Stamping die capable of automatically correcting plate deviation

A stamping die and automatic deviation correction technology, applied in the field of die stamping, can solve the problems of increased work intensity, hidden safety hazards, and low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

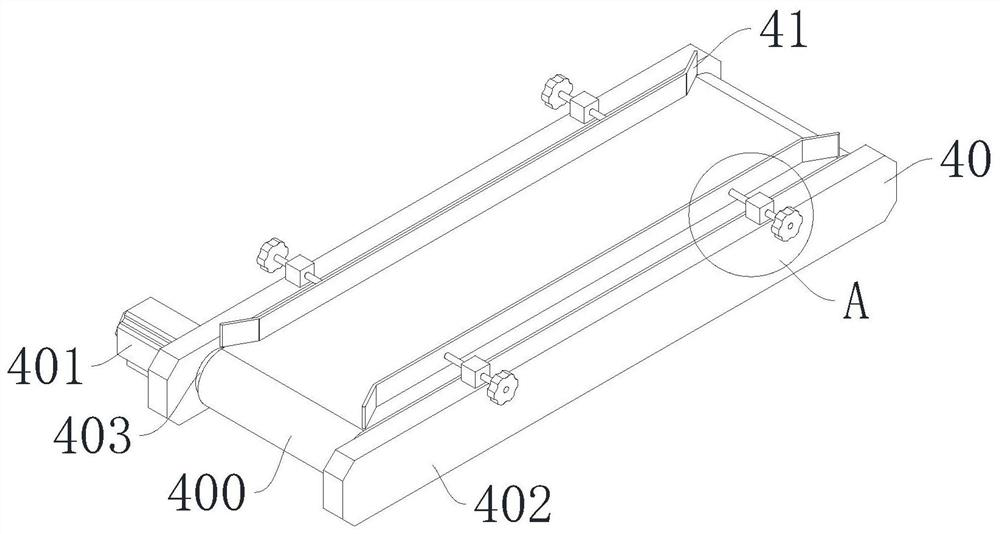

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033]Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

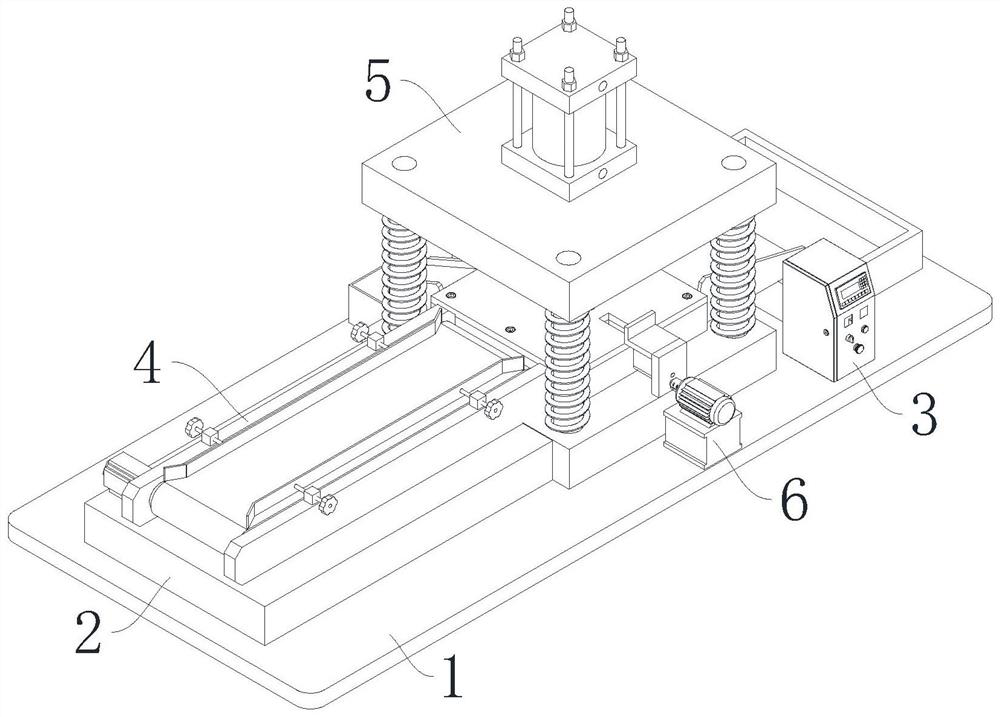

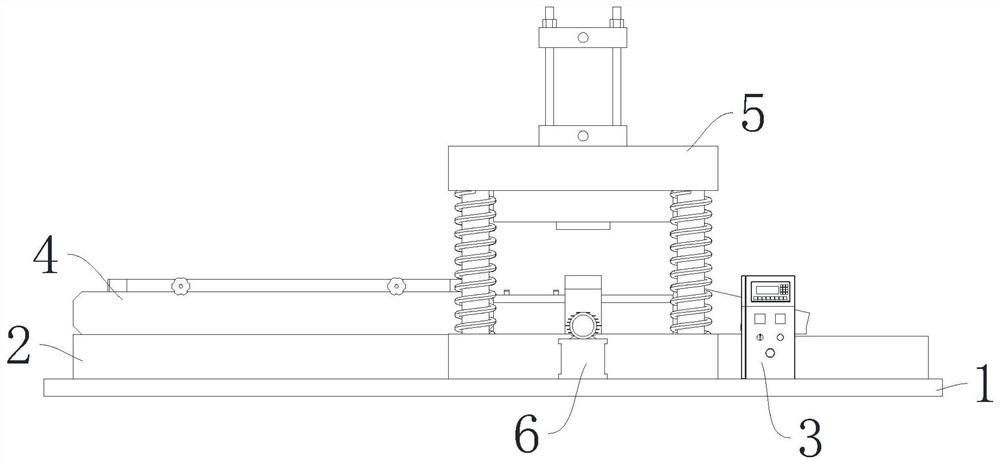

[0034] refer to Figure 1 to Figure 12 The stamping die that can automatically correct the deviation of the plate shown includes a base 1 and a base 2, and also includes a controller 3, a conveying mechanism 4, a stamping mechanism 5 and a push-fit mechanism 6, and the base 2 is fixed on the base 1 The top end of the top is used to carry the conveying mechanism 4, and the conveying mechanism 4 is fixedly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com