Control method of servo press

A servo press, servo control technology, applied in the direction of presses, manufacturing tools, etc., can solve the problem of automatic adjustment of the bottom dead center of the slider without seeing it, so as to ensure the stamping accuracy and the quality of stamping parts, and improve the stamping processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

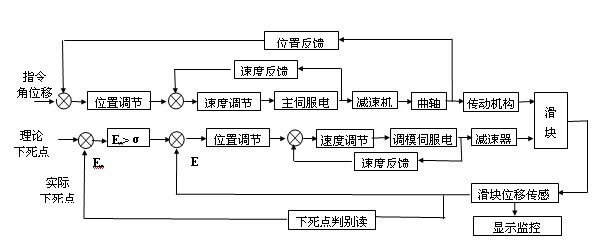

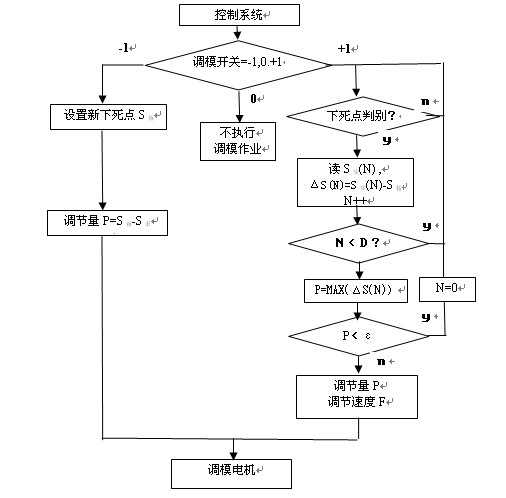

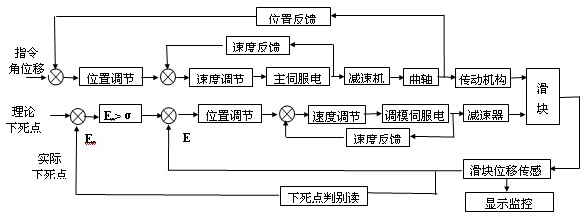

[0022] The bottom dead point control method of the present invention includes a bottom dead point reading and discrimination module, a comparison module and a threshold threshold module in the mold adjustment servo control subsystem: the bottom dead point reading and discrimination module detects each Discriminate the continuous signal of slider displacement in a stamping servo control working cycle, and read the bottom dead point position value in the current cycle; the comparison module compares the read current bottom dead point position value with the system setting value. , to calculate the offset of the current bottom dead center of the slider; the threshold threshold module is responsible for comparing the offset of the current bottom dead center of the slider with the set threshold threshold, if the offset of the bottom dead point is greater than the set threshold threshold, the system will Start the mold adjustment servo control subsystem, and adjust the slider to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com