Rotary type multihead sealing machine capable of automatically identifying file thickness

An automatic identification and rotary technology, applied in stamping, printing, etc., can solve the problems of unclear nature of documents, limited application range, chaotic management, etc., and achieve the effect of improving stamping efficiency, clear and standard stamping, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

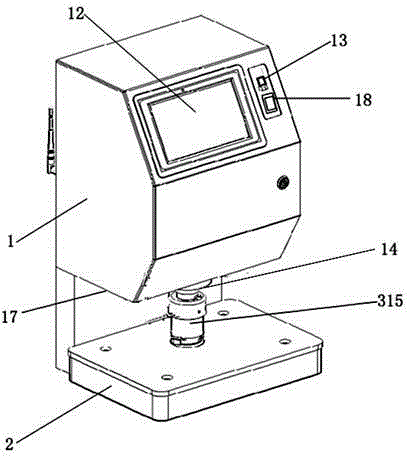

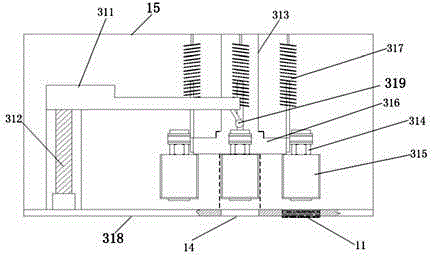

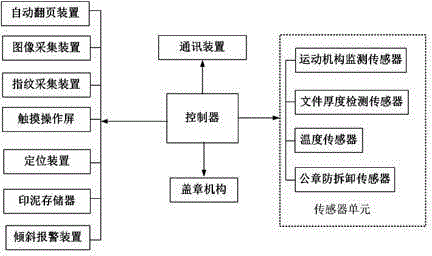

[0034] The rotary multi-head stamping machine for automatically identifying the thickness of documents of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] Such as Figure 1-4 As shown, the rotary multi-head stamping machine includes a machine head and a base 2, a housing 15 is arranged in the machine head 1, and a rotating mechanism, a stamping mechanism, a pressing mechanism and a fixing table are arranged in the housing 15 318 ; wherein, the rotating mechanism includes a supporting main shaft 313 and a rotating table 316 , and the rotating table 316 is connected to the supporting main shaft 313 through a rotating bearing, and can rotate around the supporting main shaft 313 .

[0036] The lower part of the supporting spindle 313 is fixedly connected with the fixed table 318; the stamping mechanism is arranged on the rotary table 316, and is slidably connected with the rotary table through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com