Automatic stamping device for product packaging box

A technology for packaging boxes and products, applied in printing, stamping and other directions, can solve the problems of multi-manual operation, inefficiency, automation, etc., and achieve the effect of improving stamping efficiency, high degree of automation, and high stamping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

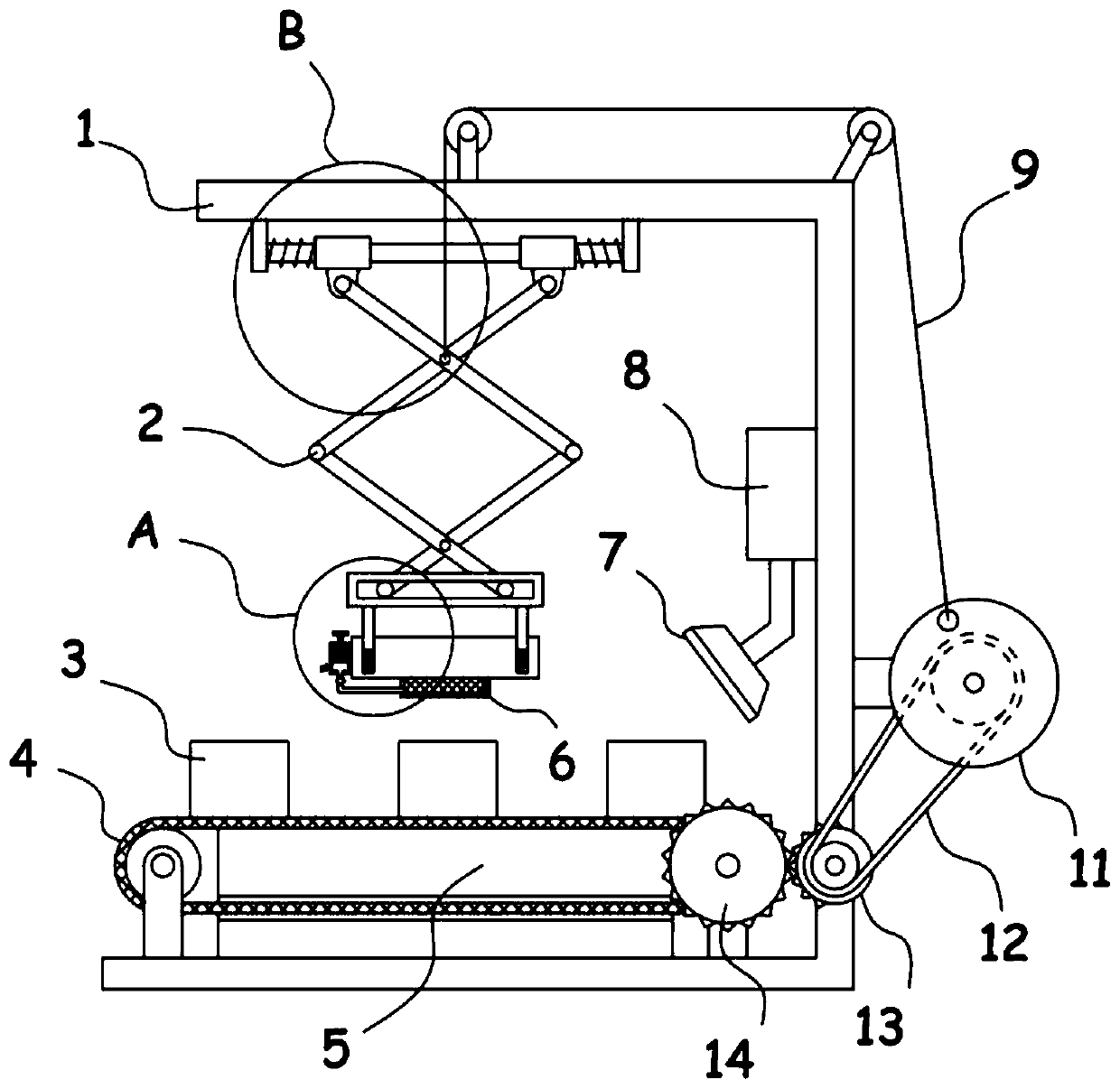

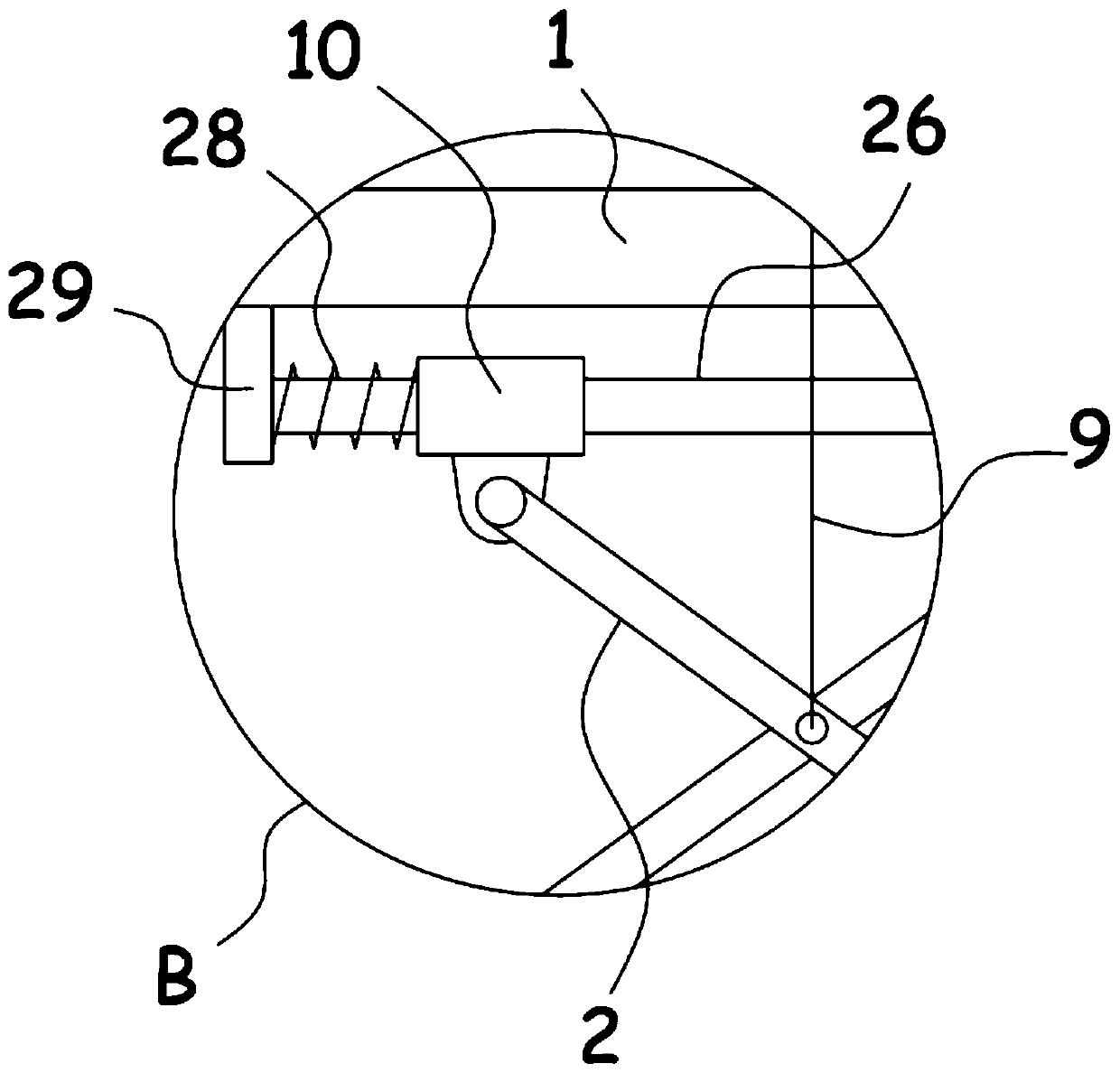

[0022] see Figure 1-4 , an automatic stamping device for product packaging, including a support frame 1 and a support bottom block 5, the support frame 1 is provided with a conveyor belt 4 for transporting the packaging box 3, and the upper surface of the support bottom block 5 is in contact with the inner wall of the conveyor belt 4 Then, a turntable 11 is installed on the support frame 1, and the turntable 11 is driven and connected with a telescopic frame 2 through a driving mechanism. There is a transmission gear 14, and the transmission gear 14 is connected to the rotating disk 11 through a stepping mechanism.

[0023] The device transports the packaging box 3 on it through the conveyor belt 4, so that the packaging box 3 moves to the right below the stamping assembly, and the driving mechanism drives the stamping assembly to move downward through the connecting assembly to realize the cover of the packaging box 3. chapter action.

[0024] Specifically, the driving mec...

Embodiment 2

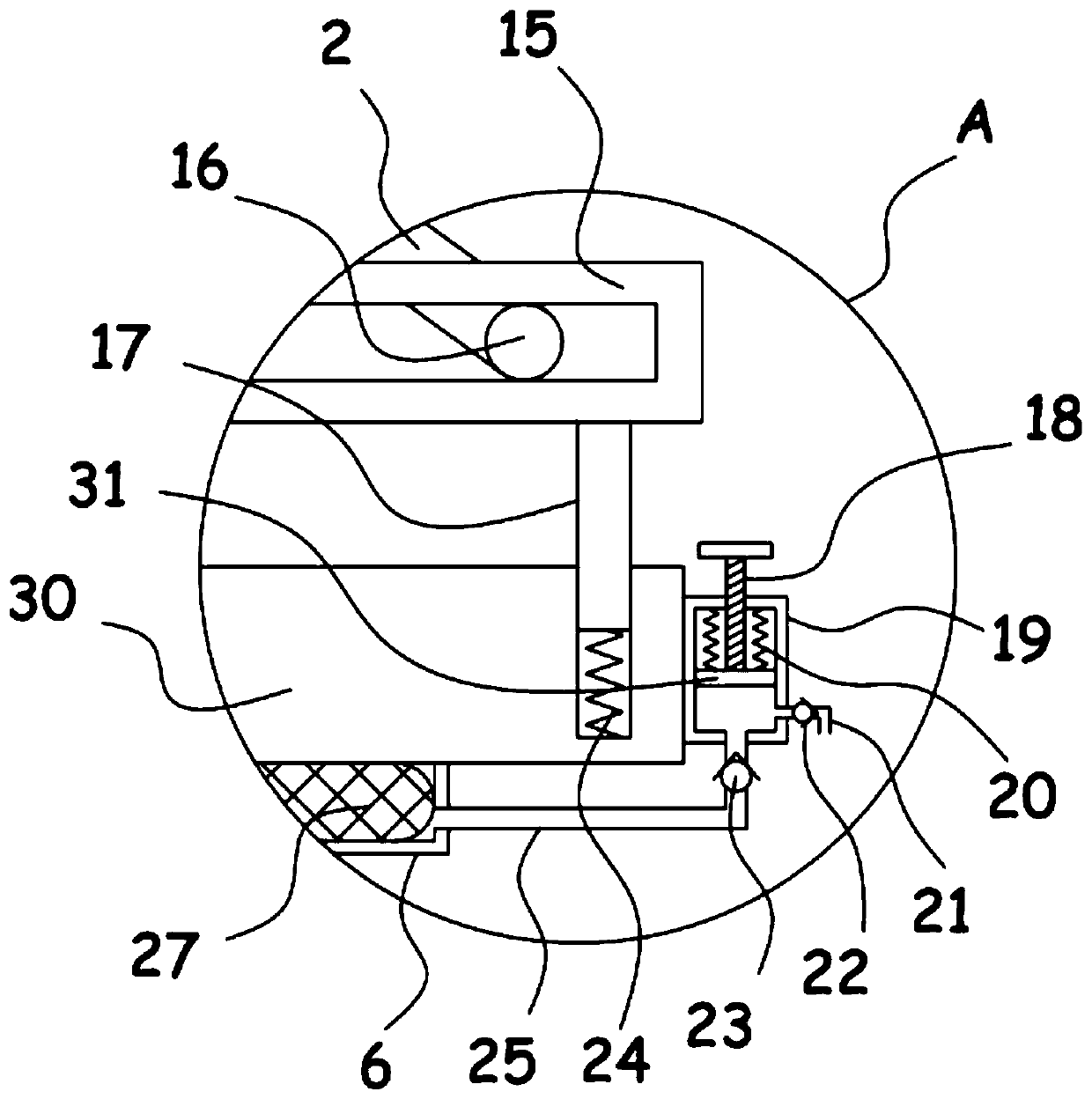

[0028] In order to further improve the sealing quality of the packaging box 3, on the basis of Embodiment 1, the connecting assembly of the device includes a connecting block 30 and a circular frame 15, and the lower end of the telescopic frame 2 is fixed with a transmission pin that slides through the circular frame 15 The column 16 and the bottom of the circular frame 15 are fixed with several guide rods 17 which are slidably connected with the connecting block 30 , and a telescopic spring 24 is fixedly connected between the guide rods 17 and the connecting block 30 .

[0029] During the expansion and contraction process of the telescopic frame 2, the transmission pin 16 is in sliding contact with the return frame 15 to realize the vertical movement of the return frame 15. During the stamping process, the seal 6 contacts the packing box 3, and the return frame 15 drives The guide rod 17 slides downward relative to the connecting block 30. At this time, the telescopic spring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com