Two-way horizontal servo pressure machine for transmission of planet roller lead screw

A technology of servo presses and planetary rollers, applied to presses, stamping machines, transmissions, etc., can solve the problems of increasing design and manufacturing costs, limiting the frequency of forward and reverse rotation of motors, increasing structural complexity, etc., and achieving reduction Power, improved motor life, the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

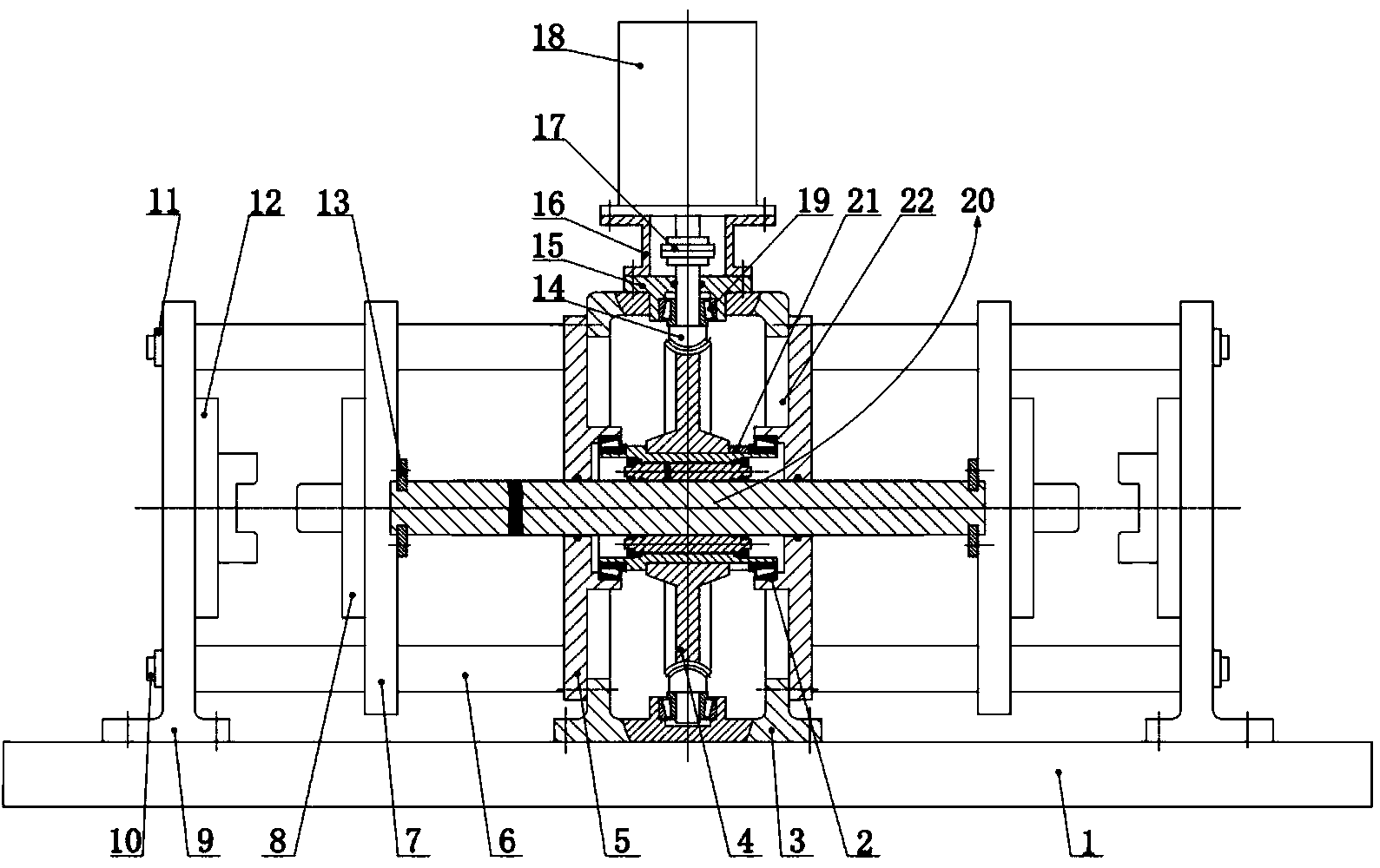

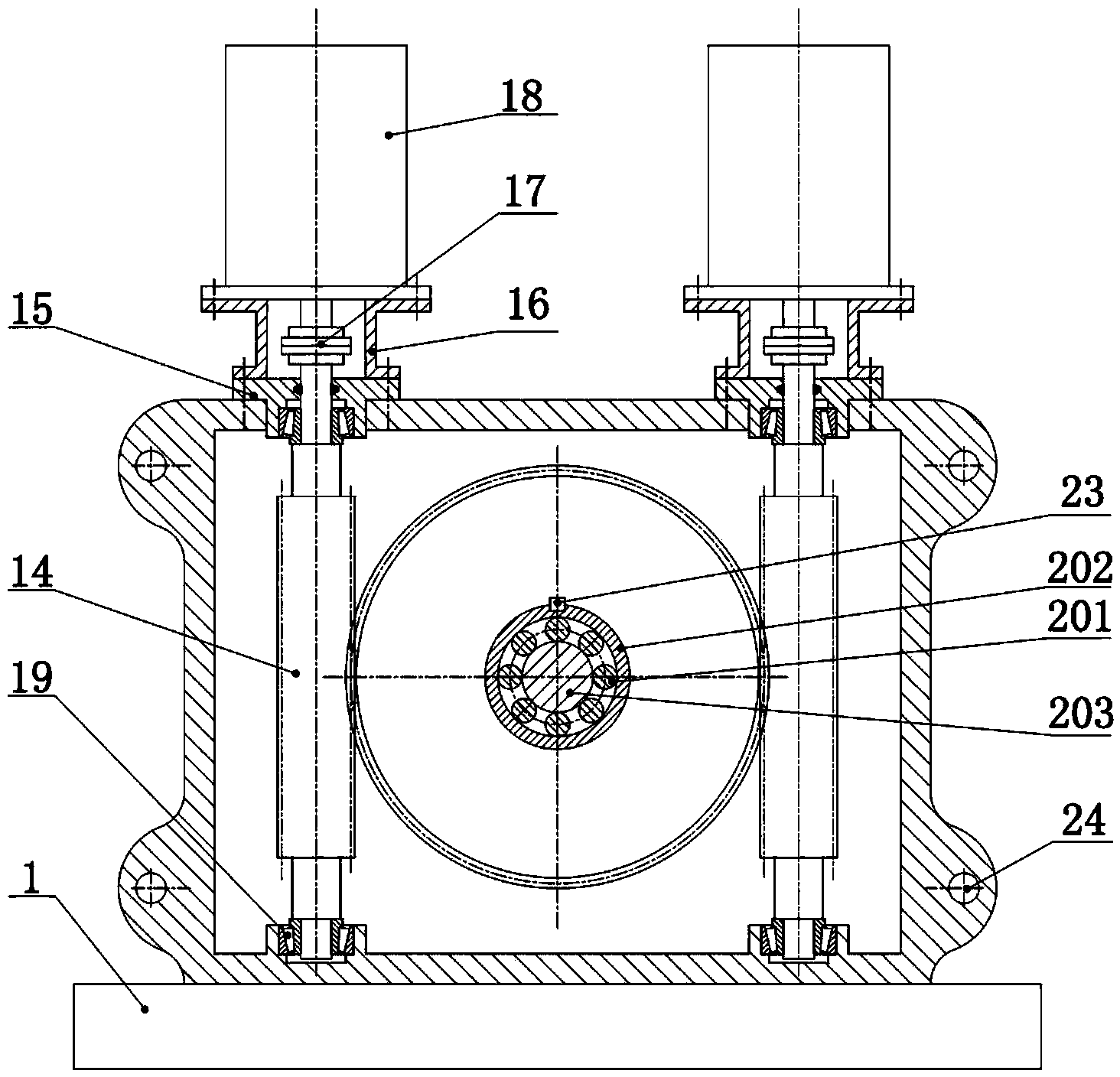

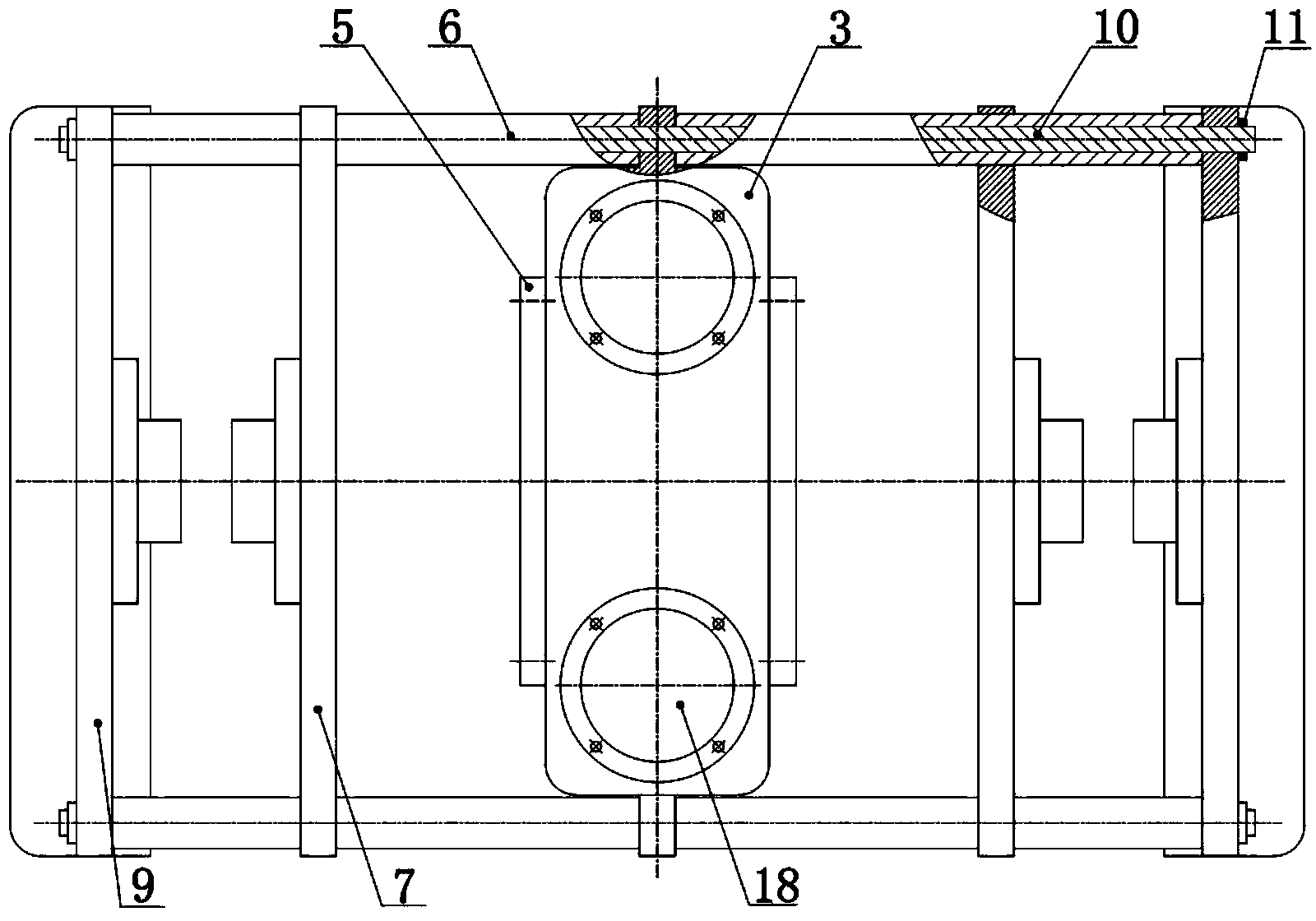

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 , image 3 As shown, a two-way horizontal servo press driven by a planetary roller screw, including a body 3, the body 3 is fixed on the base 1 by bolts, the body 3 is placed in the middle of the press, and the two sides of the body 3 are processed There is a through hole 22, and the diameter of the through hole 22 is larger than the diameter of the worm wheel 4. When installing, the worm wheel 4 is put into the through hole 22 of the fuselage 3, and the side end cover 15 is connected with the fuselage 3 by bolts to seal the through hole 22 to prevent dust from entering. The screw 203 passes through the two side end covers 15, the screw 203, the outer surface of the roller 201 and the inner surface of the nut 202 are processed with threads, the three are engaged together through the threads, and the two ends of the nut 202 are embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com