Automatic trimming and reshaping integrated automobile stamping die and stamping process thereof

A stamping die and two-in-one technology, applied in the field of automobile stamping dies, can solve the problems of affecting stamping production efficiency, complex stamping process, waste of mold materials, etc., to solve the problems of slow mold replacement, improve stamping efficiency, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment takes the fuel tank cap of an automobile as an example, and its product depth is about 100 mm. For other similar auto-related accessories, the automatic trimming and shaping two-in-one automobile stamping die structure can refer to this example.

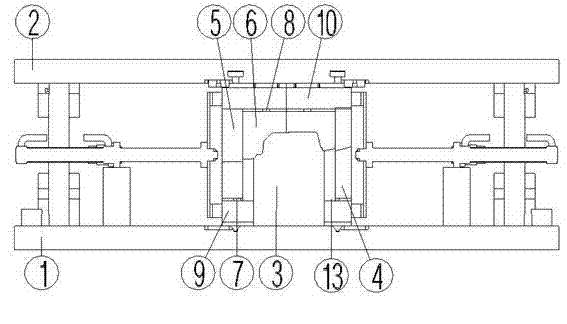

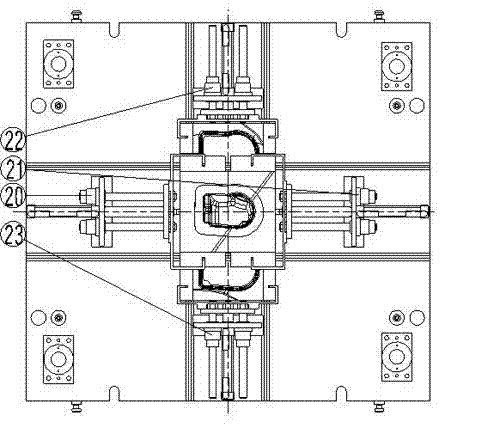

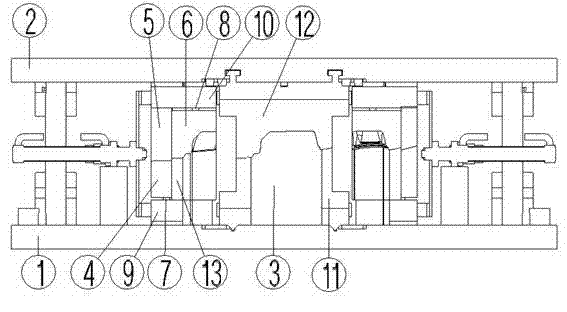

[0019] Such as figure 1 Shown in -4, the present invention comprises lower mold base 1, upper mold base 2, trimming punch 3, trimming stripper plate 4, trimming die 5 and trimming pressure plate 6, described trimming punch 3 is fixed on the lower mold base 1. The lower mold base 1 is fixed on the lower table of the machine tool, the upper mold base 2 is fixed on the upper table of the machine tool, and the upper and lower mold bases are guided by guide posts. Guide rails are set on the upper and lower mold bases; a lower fixed plate 9 is set on the left and right guide rails of the lower mold base 1, and a trimming stripper 4, a second trimming punch 13 and a lower spring are set on the lower fixing plate 9 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com