Belt type loading device applied to numerical-control circular sawing machine

A technology of belt-type and circular sawing machines, which is applied in sawing machine devices, metal sawing equipment, metal processing, etc. It can solve problems such as the inability to hoist a whole bundle, the inability to realize double-root cutting, and the inability to clamp, etc., to achieve Effects of reducing frictional resistance, saving cutting time and cost, and widening the range of shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following structural drawings further illustrate the present invention.

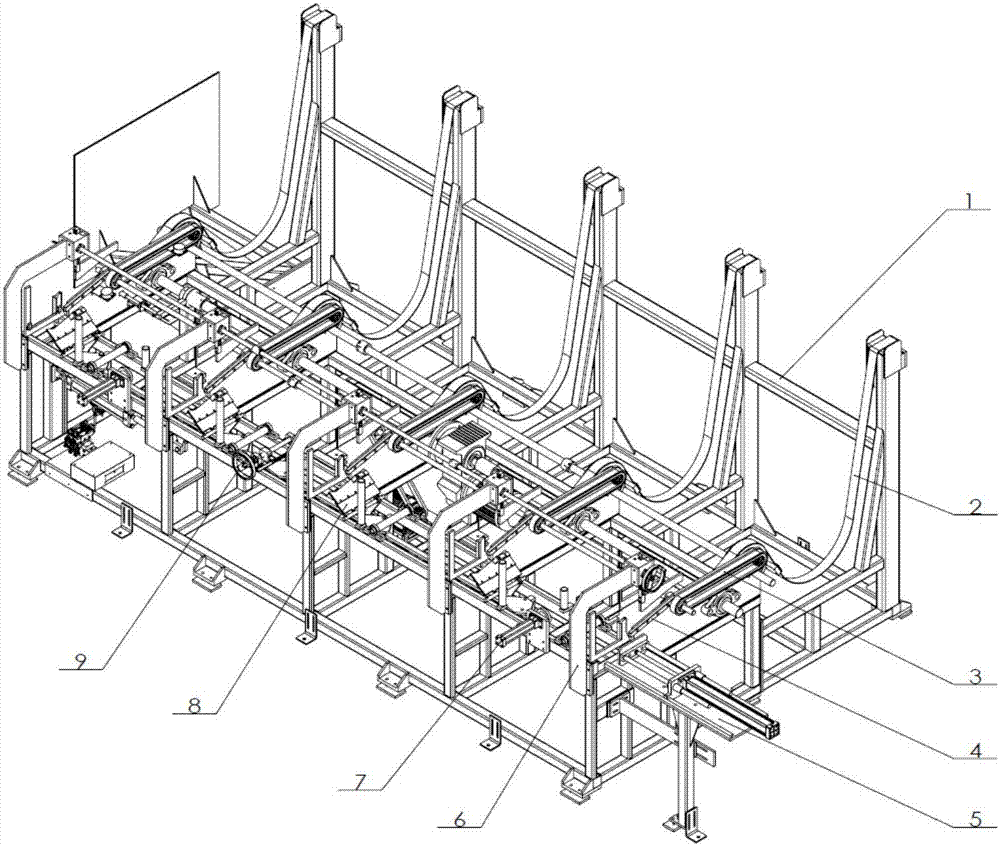

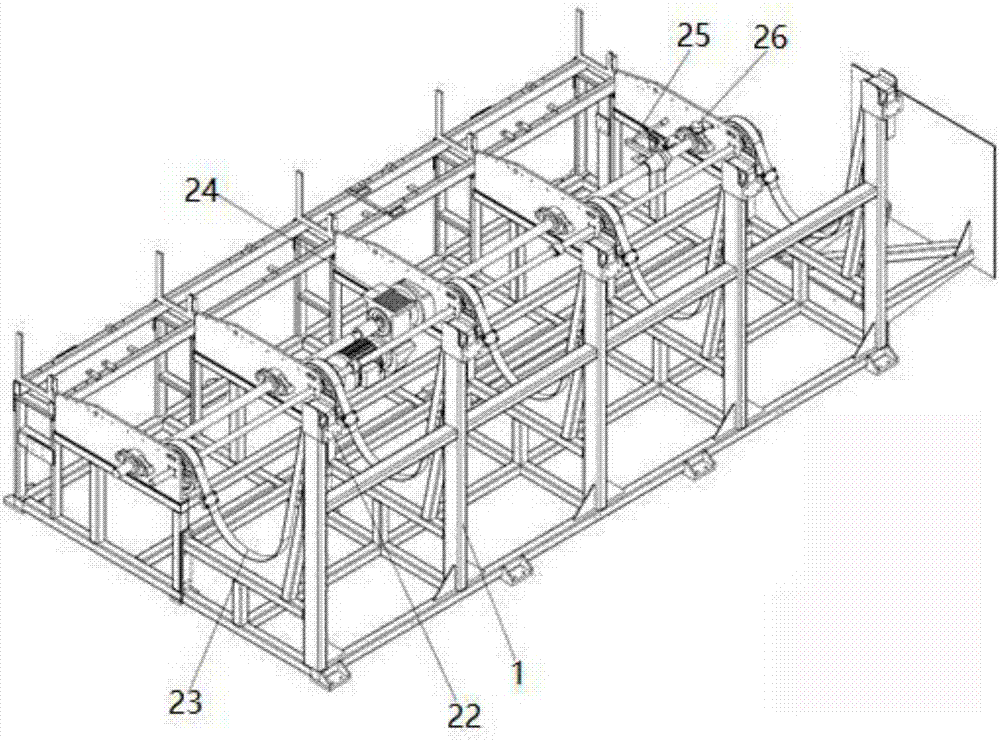

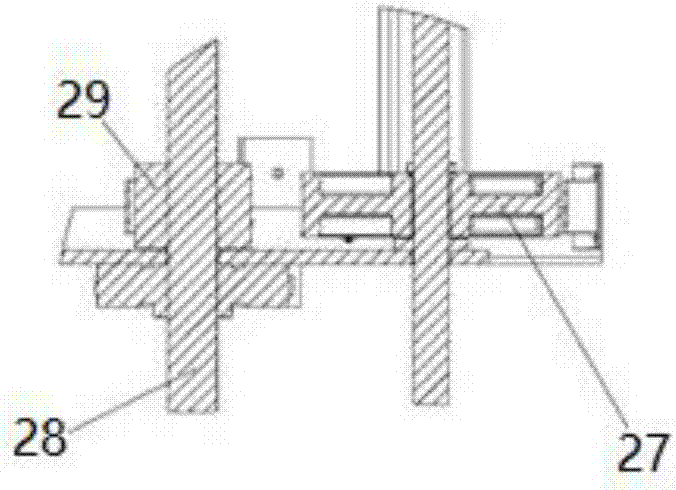

[0037] The belt type feeding mechanism such as figure 1 As shown, it mainly consists of a loading rack base 1, a pulley assembly 2, a chain conveying assembly 3, an inclined support plate 4, a cylinder pushing assembly 5, a stopper adjustment assembly 6, a clamping cylinder assembly 7, an overturning cylinder assembly 8 and a bar Diameter adjustment assembly 9 etc. constitute.

[0038] Hoist the whole bundle of bars on the belt of the pulley assembly 2, and tighten the belt through the parallel shaft reduction motor on the pulley assembly 2, so that the bars roll down to the chain of the chain conveying assembly 3, and the small deceleration of the chain conveying assembly 3 The motor drives the bar to move to the inclined support plate 4, adjust the height of the block of the stop adjustment assembly 6 according to the diameter of the bar, control the bars to pass one by one, and then adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com