Pipe double end chamfering machine

A double-head chamfering machine and pipe technology, which is applied to machine tool parts, metal processing machinery parts, clamping, etc., can solve the problems of labor hours and low efficiency, save time, improve processing efficiency, and reduce production costs and resource effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

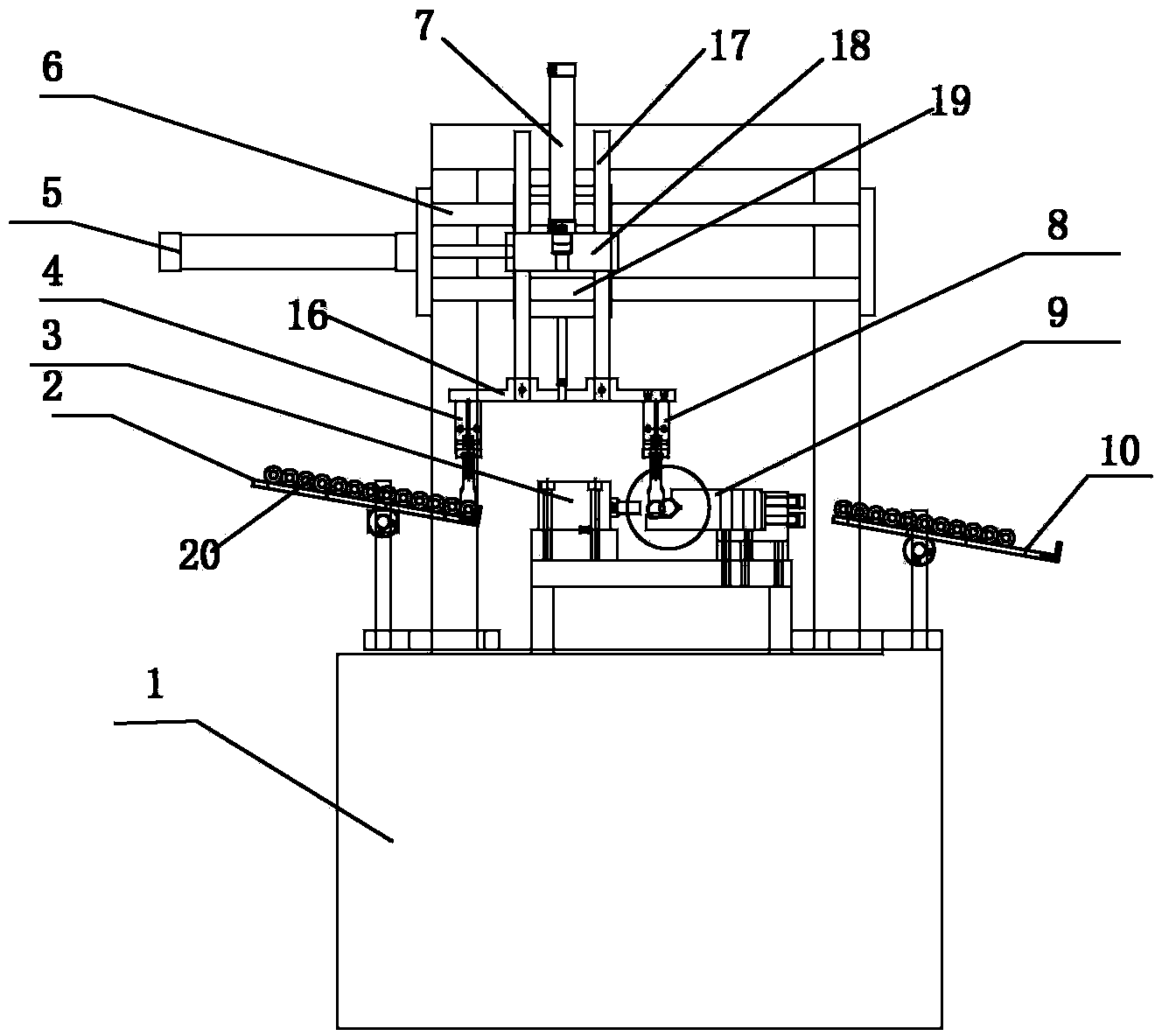

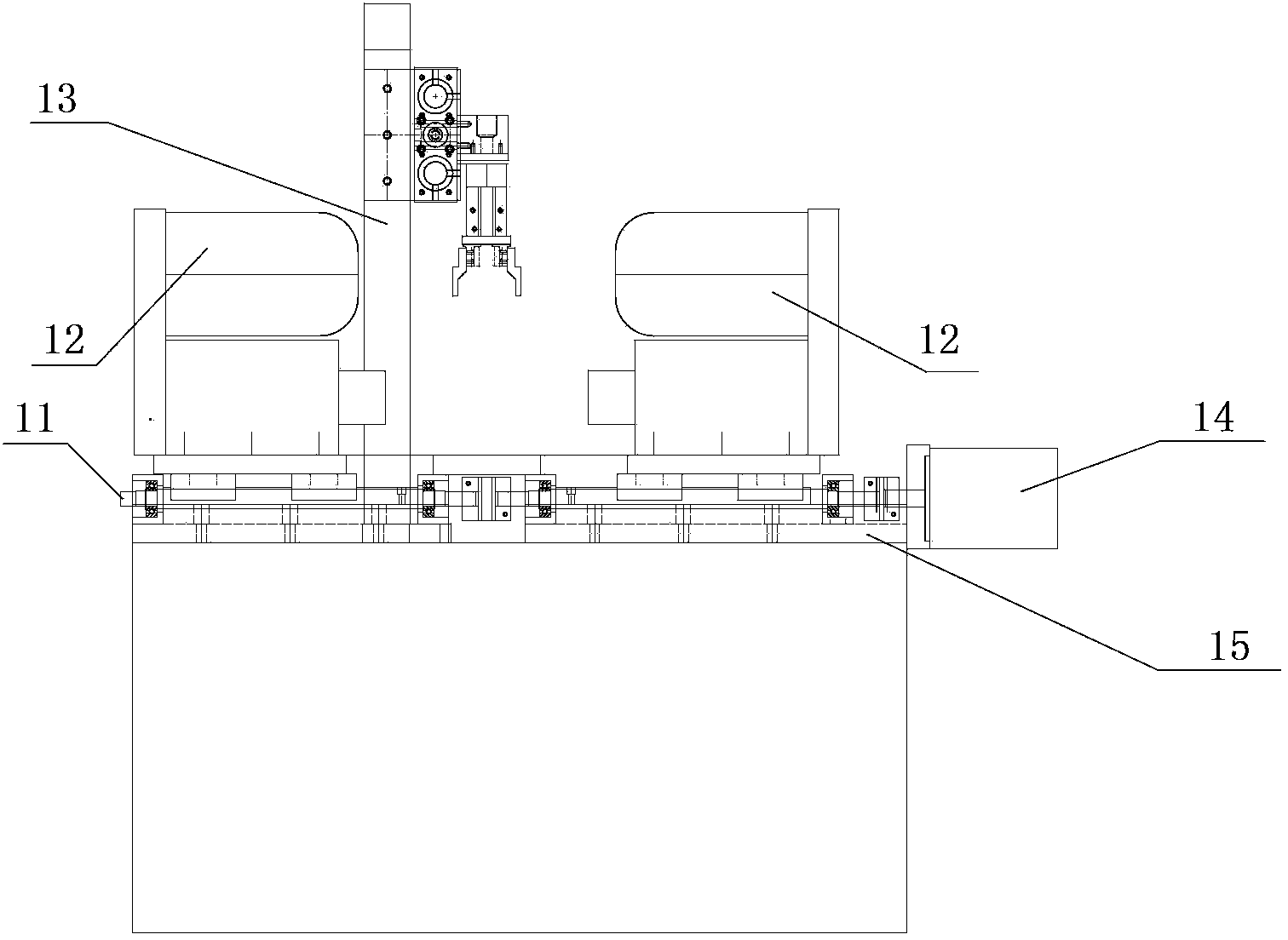

[0015] see attached figure 1 , 2 , the present invention provides a kind of pipe double-head chamfering machine, comprising a bed 1, a material loading and unloading mechanism, a chamfering processing mechanism, a clamping mechanism, an upper material bin 2, and an unloading material bin 10. The feeding mechanism, the chamfering processing mechanism and the clamping mechanism are fixed on the bed, the upper feeding bin is fixed on the left side of the bed, the lower feeding bin is fixed on the right side of the bed, and the feeding and unloading mechanism includes a vertical cylinder 7. Guide rail 6, horizontal cylinder 5, feeding pneumatic finger 4 and unloading pneumatic finger 8, the feeding pneumatic finger and unloading pneumatic finger are connected to the guide post 17 through the connecting bracket 16, and the guide post is connected to the vertical guide plate 18 is slidingly connected, the connecting bracket is connected with the vertical cylinder 7, the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com