Automatic coiling device for steel strip coil with inner ring provided with folding head and use method thereof

A steel coil and inner ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to roll up, narrow inner diameter variation range, large folding head size, etc., achieving a high degree of automation and a wide range of applications , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

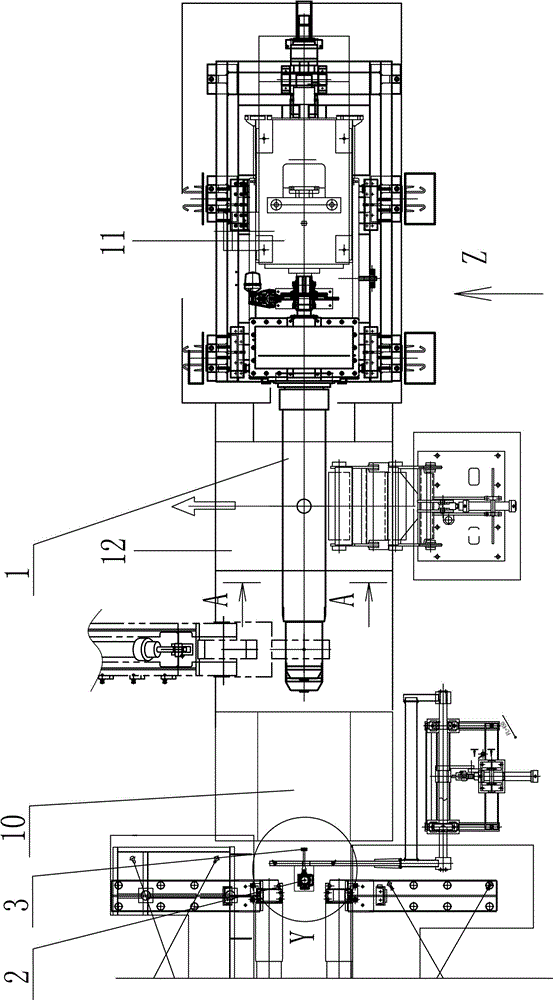

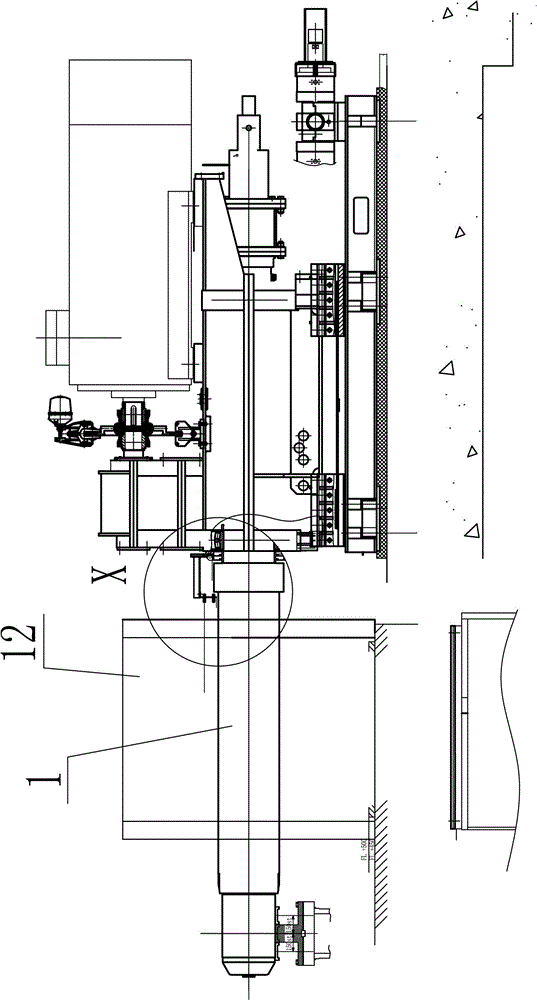

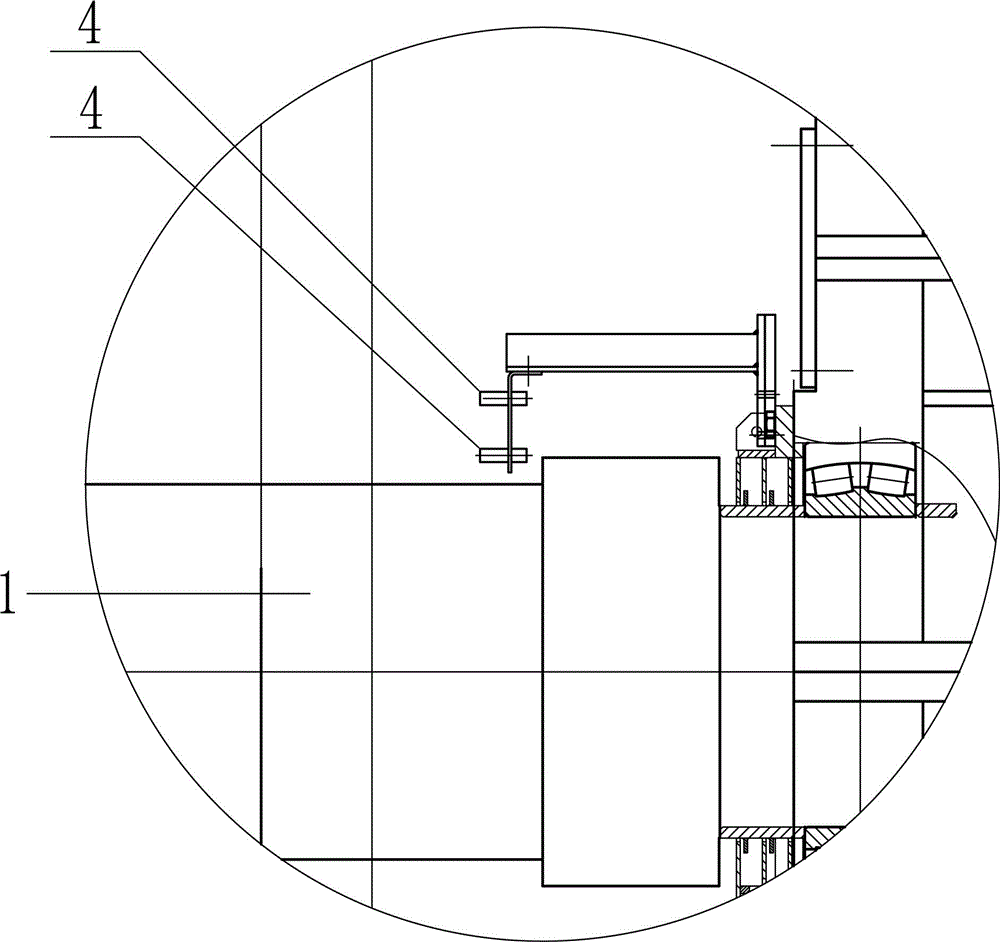

[0025] An automatic winding device for a steel coil with a folded head on the inner ring, including an uncoiler 1, a gear motor 2, a laser rangefinder 3, a laser probe 4 and a sleeve 5, such as Figure 1 to Figure 6 As shown, the specific structure is:

[0026] The uncoiler 1 is driven by a stepping motor 11, and a reel 12 is fixed on the rotating shaft of the uncoiler 1;

[0027] The rotating shaft of the gear motor 2 is connected to the laser range finder 3 through the transmission mechanism, and the laser range finder 3 is arranged on one side of the reel 12;

[0028] There are at least two laser probes 4 and sleeves 5, and each laser probe 4 is sequentially arranged on the radial direction of the plane where the end face of the reel 12 is located. The distance between each laser probe 4 and the central axis of the uncoiler 3 rotating shaft and the The inner diameter of each sleeve 5 is matched with the inner diameter of each steel coil, and the side wall of one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com