Patents

Literature

61results about How to "Solve the problem of automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

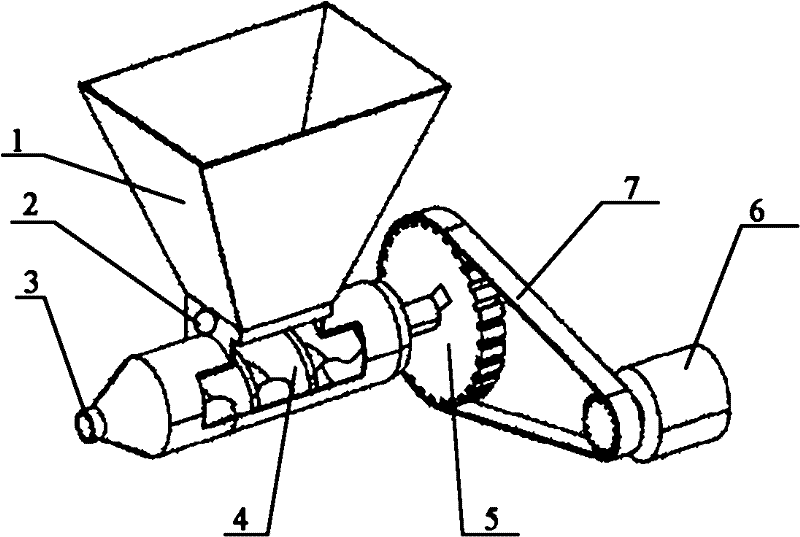

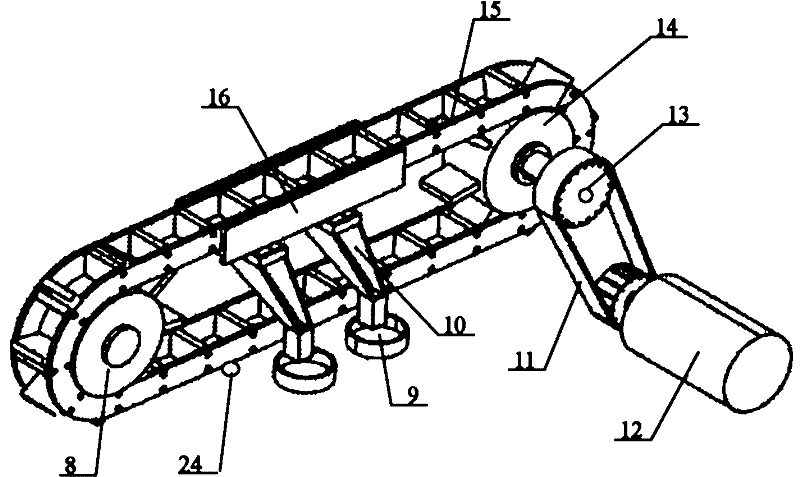

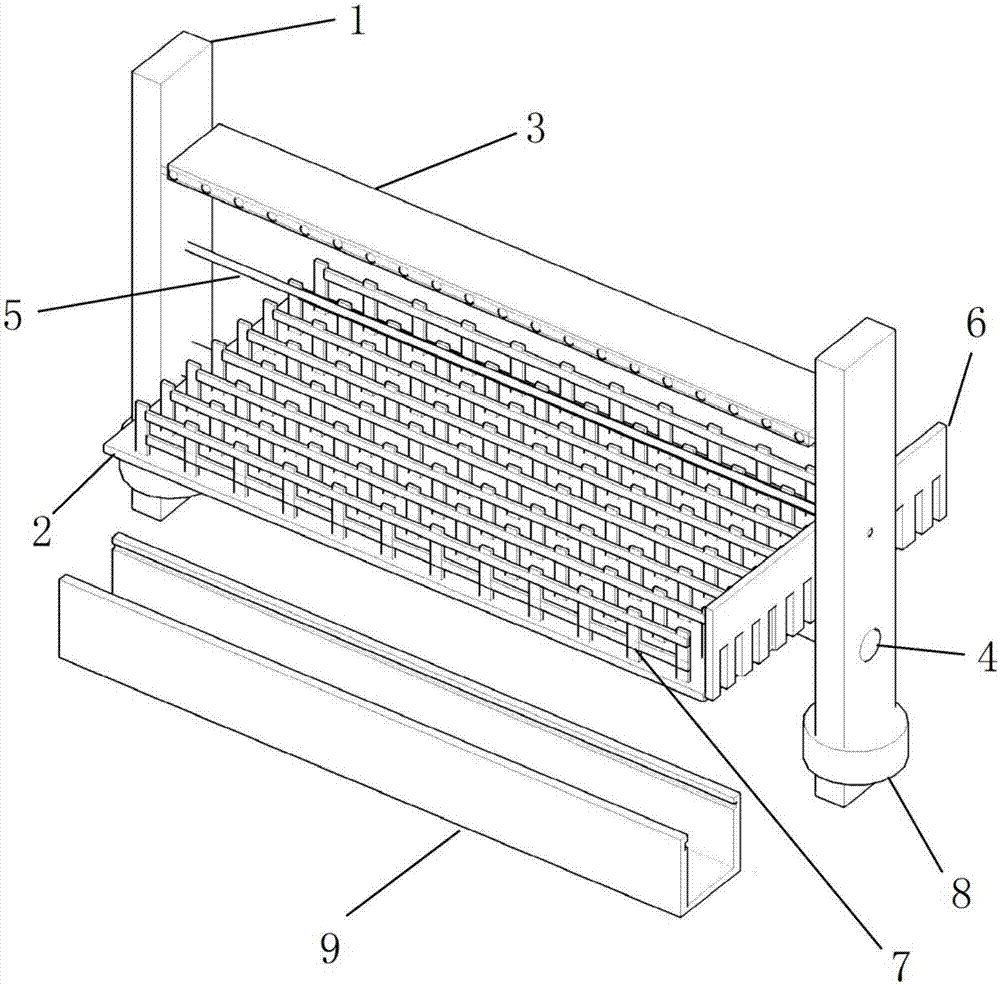

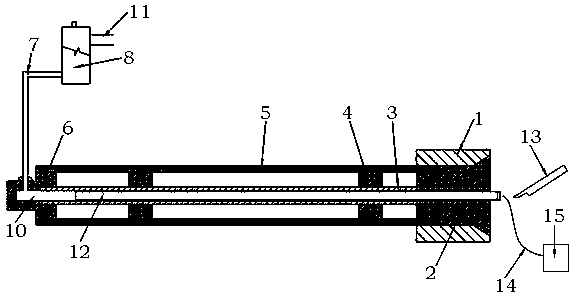

Automatic timed and quantitative feeding device for interval cages

InactiveCN102301962ARealization of automatic timing and quantitative feedingSolve the problem of automatic feedingAnimal feeding devicesAvicultureTransmission beltControl system

The invention relates to an automatic timed and quantitative feeding device for interval cages. By the automatic timed and quantitative feeding device, the problem of automatic feeding of multiple cages in the cultivation process is solved, and the automatic timed and quantitative feeding of the interval cages of cultivation enterprises is realized. The device mainly comprises a feed distribution system, a feed delivery system and a control system, wherein the feed distribution system consists of a storage hopper, a spiral batching mechanism, a belt pulley, a belt and a stepping motor; the storage hopper is fixed on a shell of the spiral batching mechanism; the spiral batching mechanism is driven by the stepping motor through the belt pulley and the belt; feeds contained in the storage hopper are outputted from a discharge hole at one end of the shell; a transmission belt in the feed delivery system is arranged at the discharge hole; a feed collection device is arranged on the lower side of the transmission belt; an outlet of the feed collection device corresponds to a feeding trough; the transmission belt is driven by the stepping motor; and the feeds inputted from the discharge hole are put into the feed collection device, and are conveyed to the feeding trough of each cage by the feed collection device.

Owner:JILIN UNIV

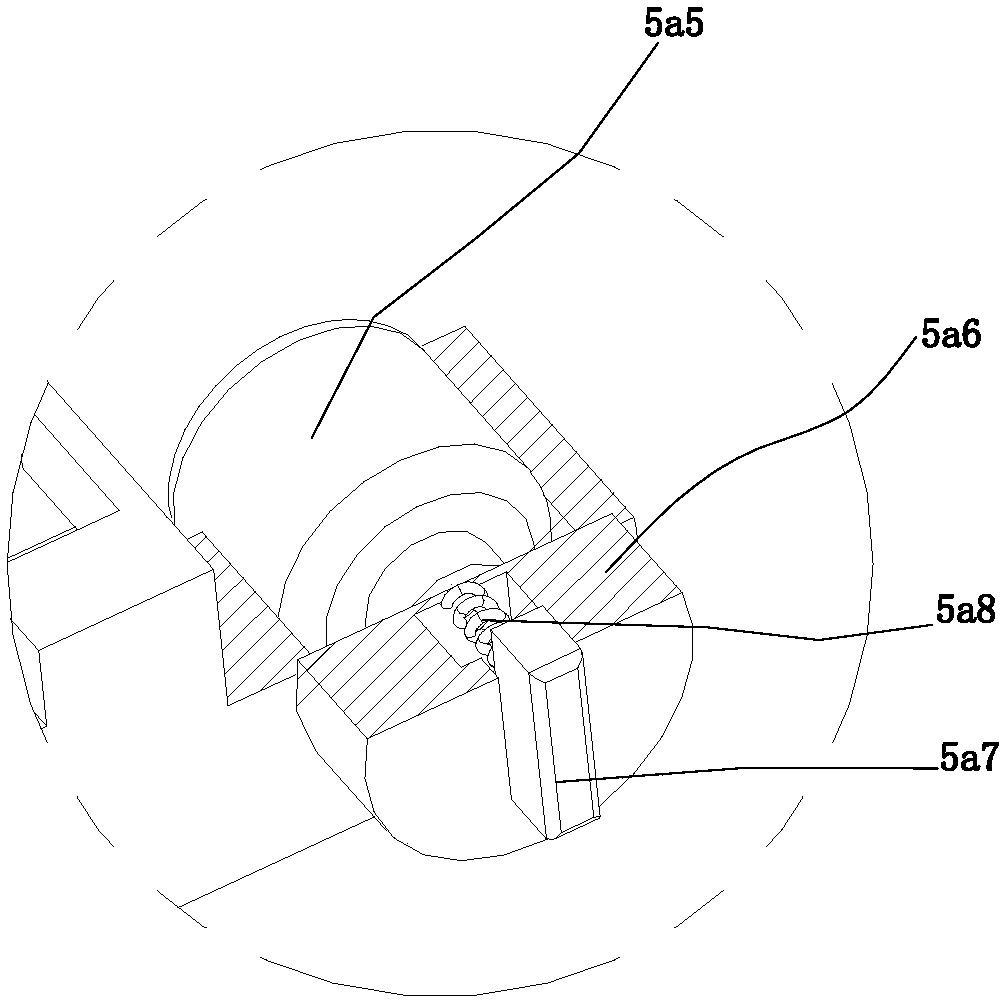

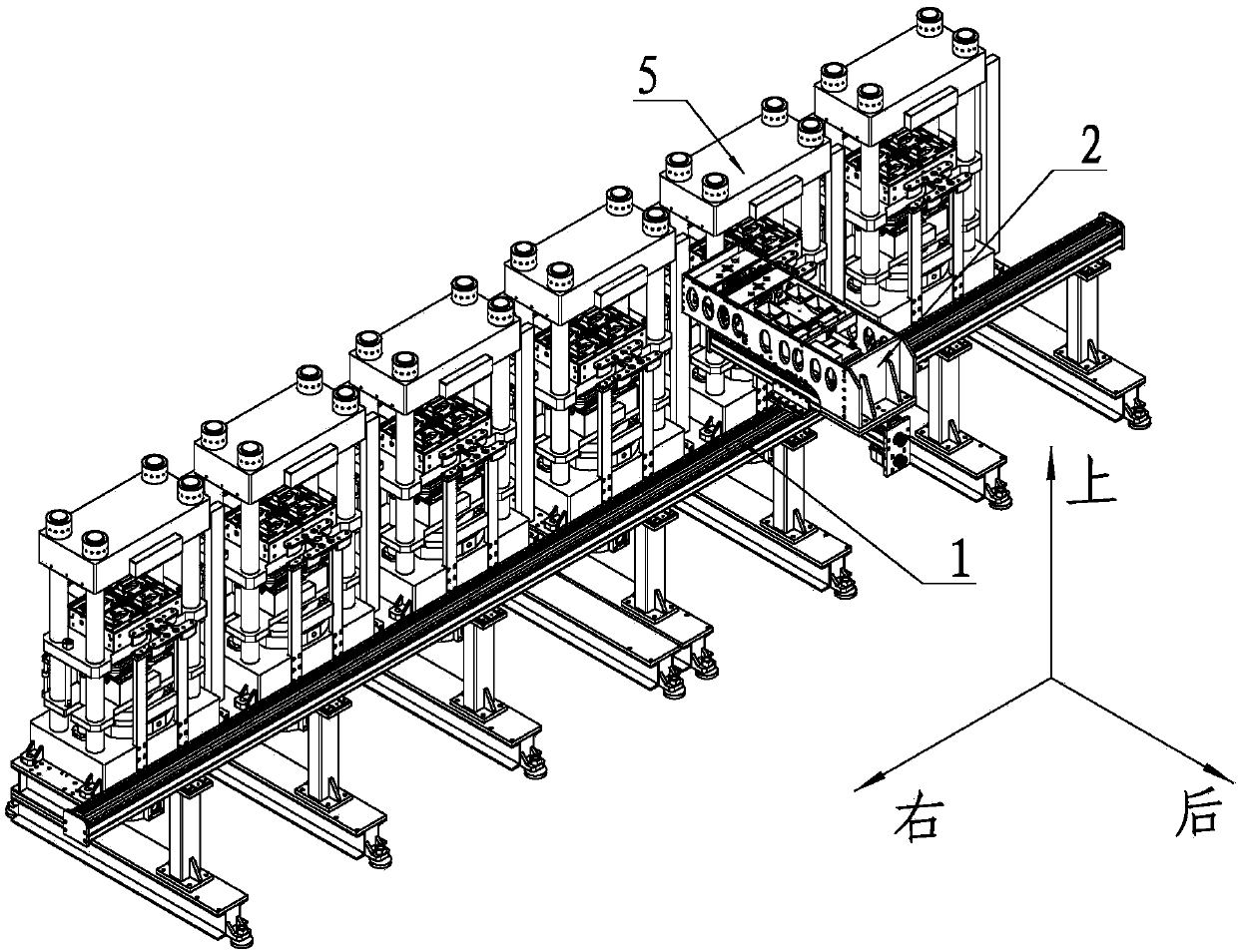

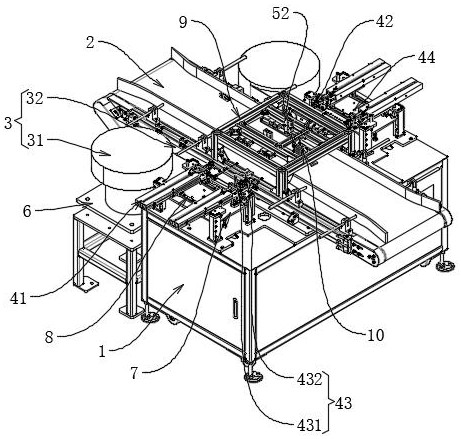

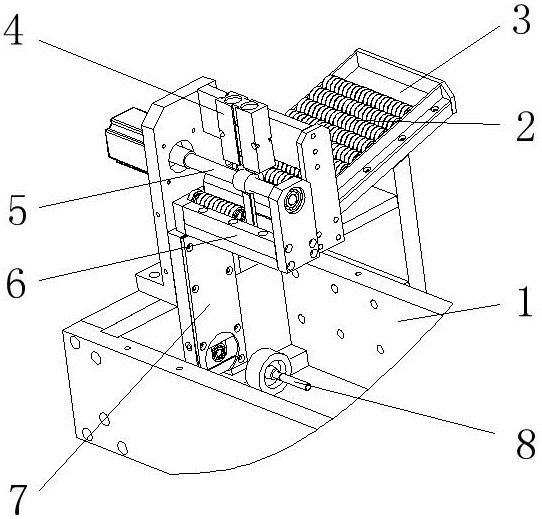

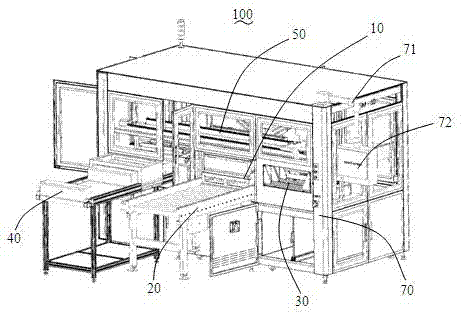

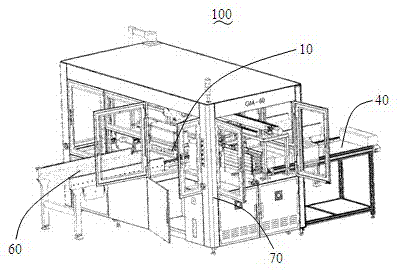

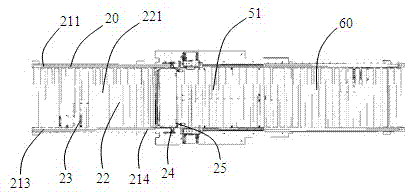

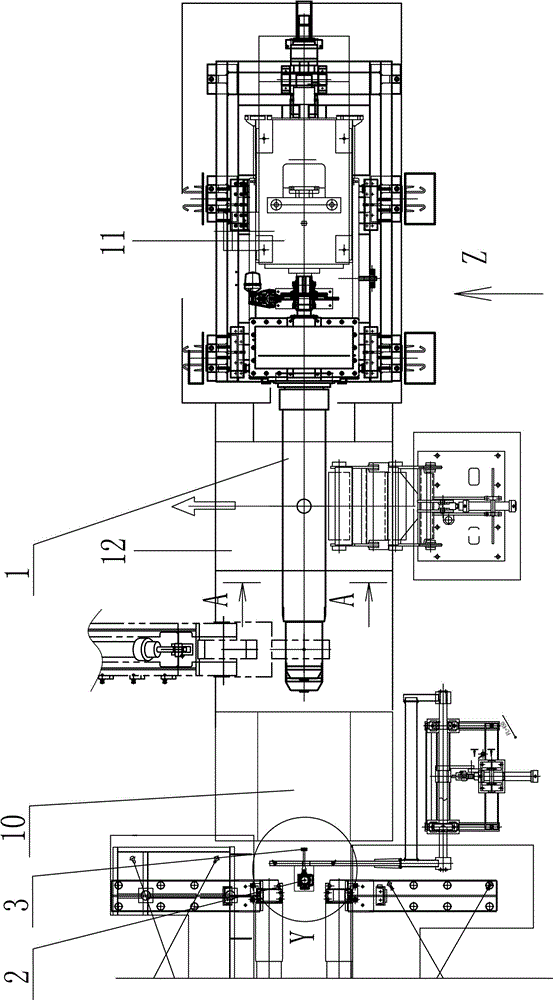

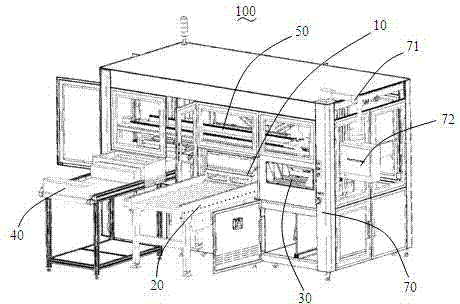

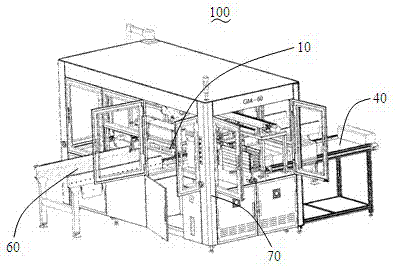

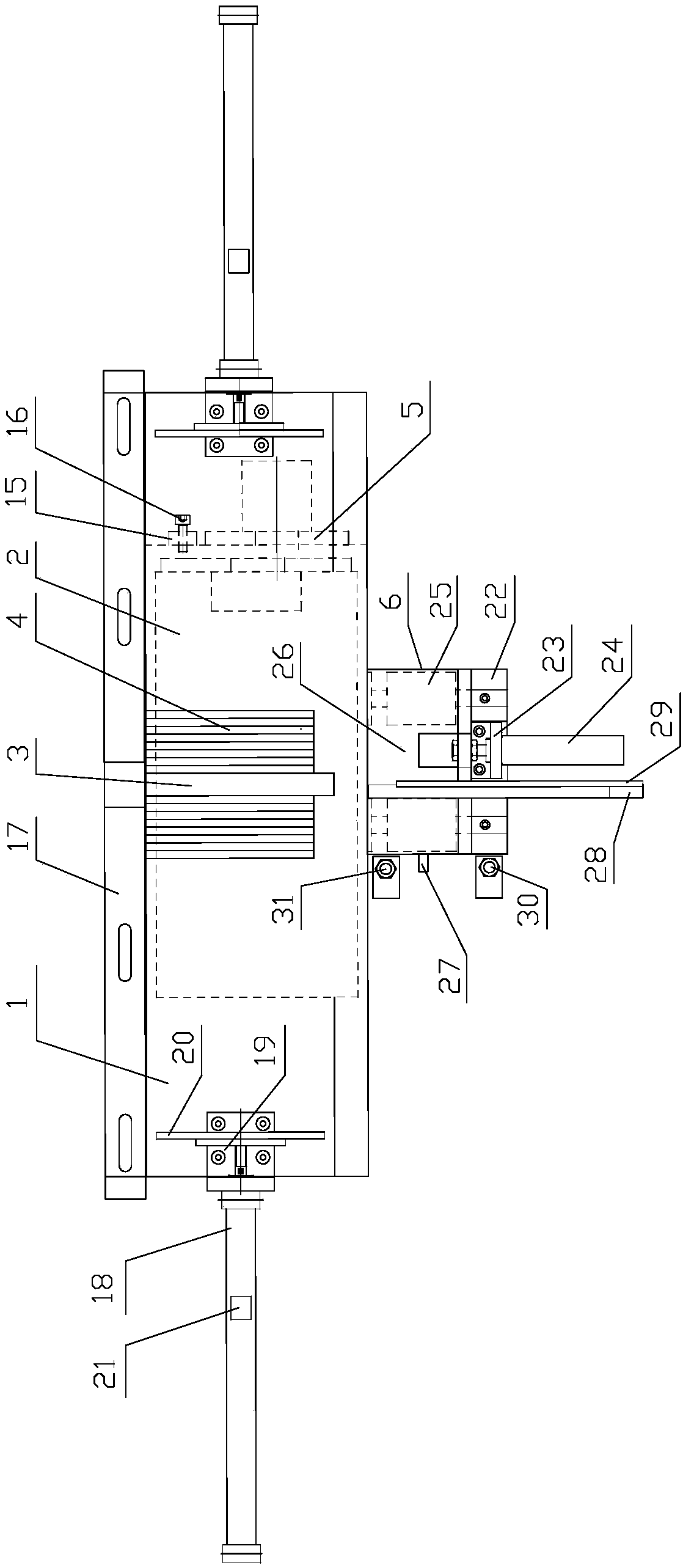

Automatic press-mounting method and equipment for optical transceiver assembling member

ActiveCN102401948AImprove efficiencyIncrease productivityAssembly machinesCoupling light guidesManufacturing technologyTransceiver

The invention discloses an automatic press-mounting method and equipment for an optical transceiver assembling member and belongs to the technical field of manufacturing optical communication devices. The automatic press-mounting method for the optical transceiver assembling member disclosed by the invention comprises the following steps of: placing a metal tail-handle, covering the upper cover of a press-mounting tool, placing a ceramic ferrule, applying pressure to the upper cover of the press-mounting tool to form a tail-handle assembly, taking away the upper cover of the press-mounting tool, screening unqualified products with poor pressure-bearing capability and skimming off products with qualified sizes and products with ultra-poor sizes. The invention further discloses automatic press-mounting equipment for the optical transceiver assembling member. According to the automatic press-mounting equipment for the optical transceiver assembling member disclosed by the invention, the automatic feeding during the press-mounting process and the full-automatic operation during the press-mounting process are solved; whether the force is out of limits and the press-mounting matching size is qualified during the press-mounting process can be judged, and the quality characteristics of the products can be selected automatically; the structure is simple and the operation is simple and convenient; the automatic operation of the complete device is realized, and the reduction of labor force, the increasing of efficiency and the reduction of cost are achieved.

Owner:FINETOP SCI &TECH

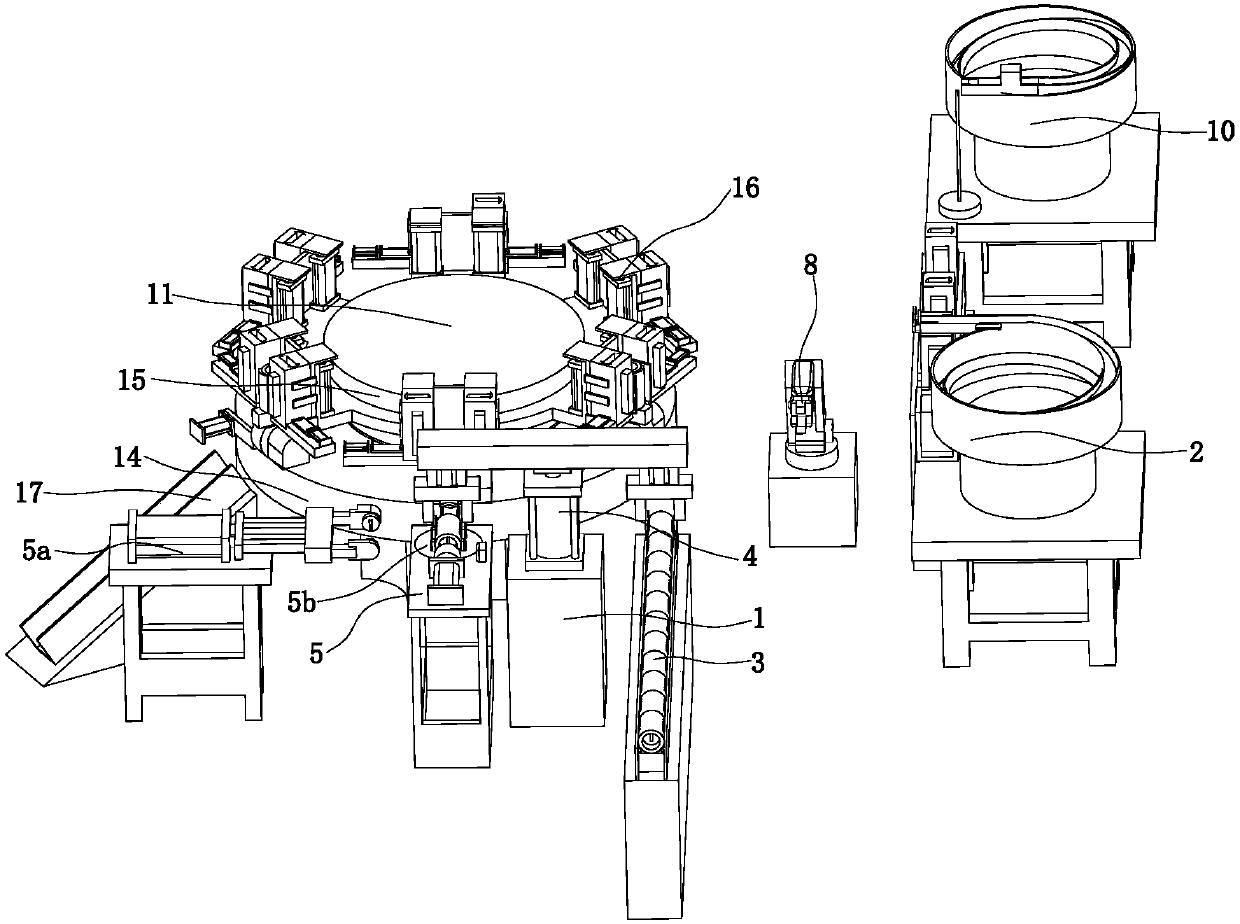

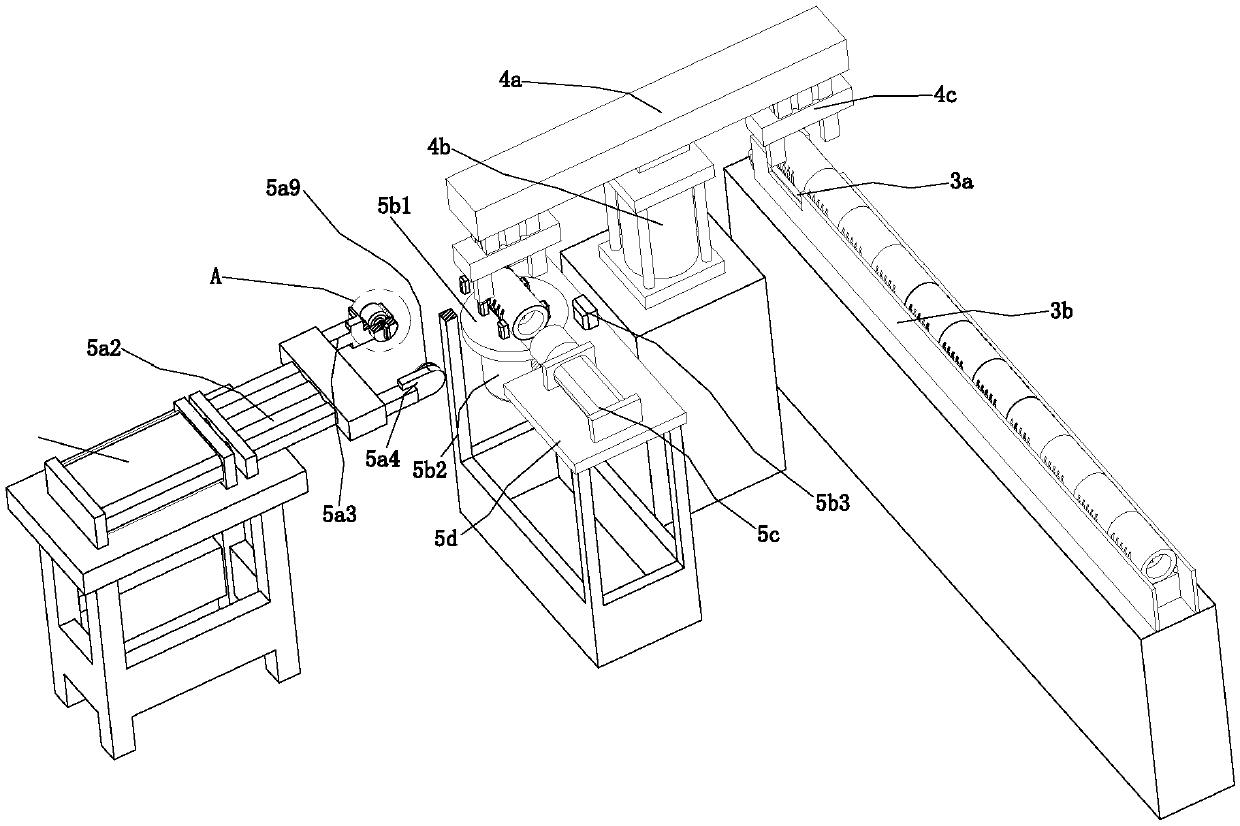

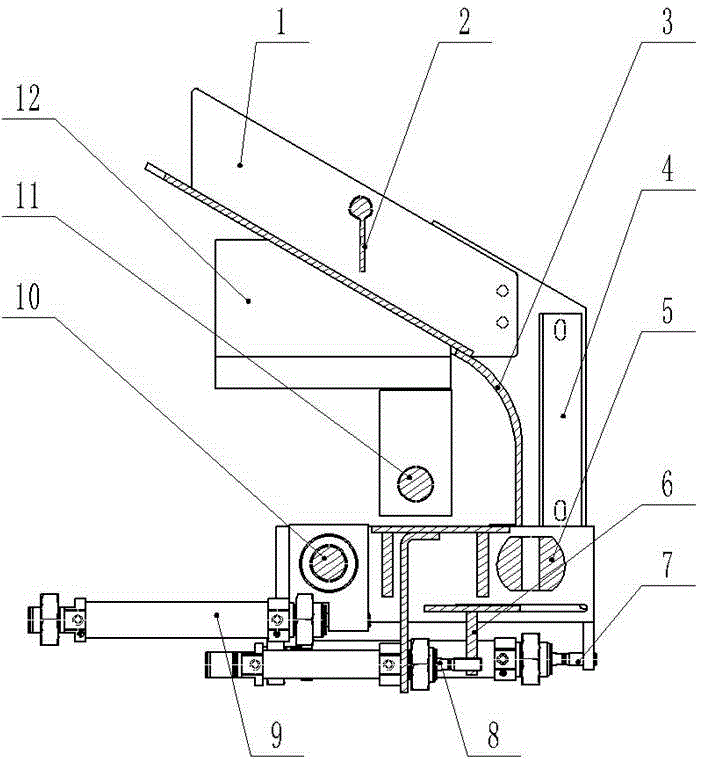

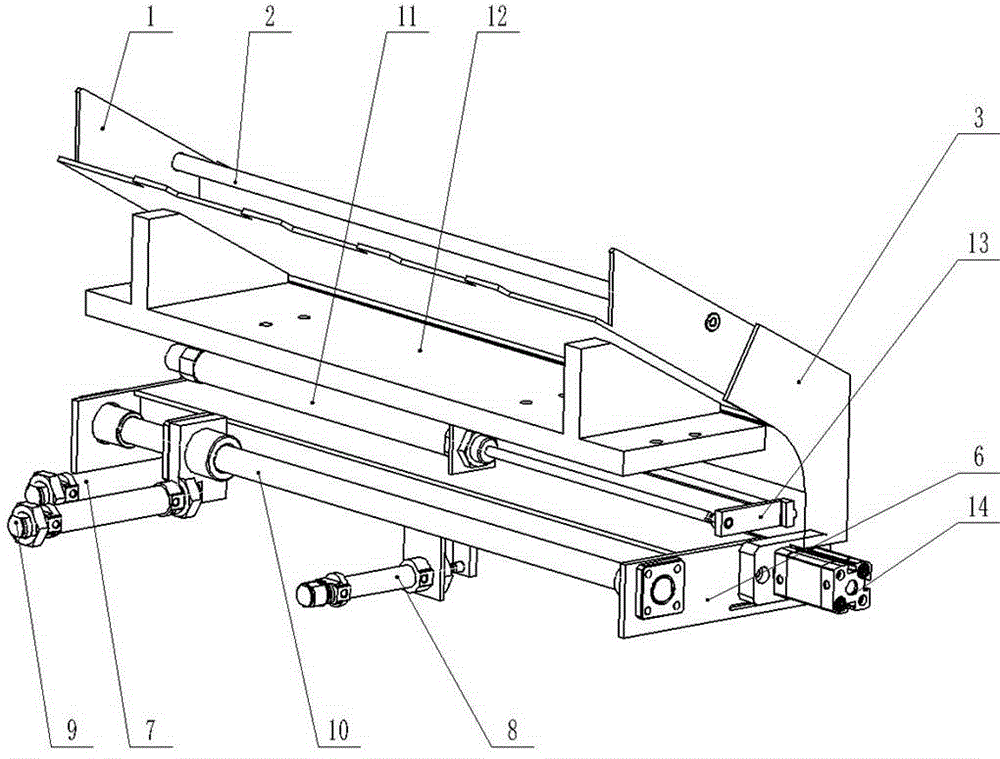

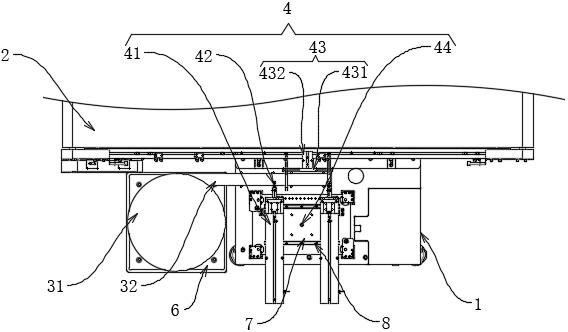

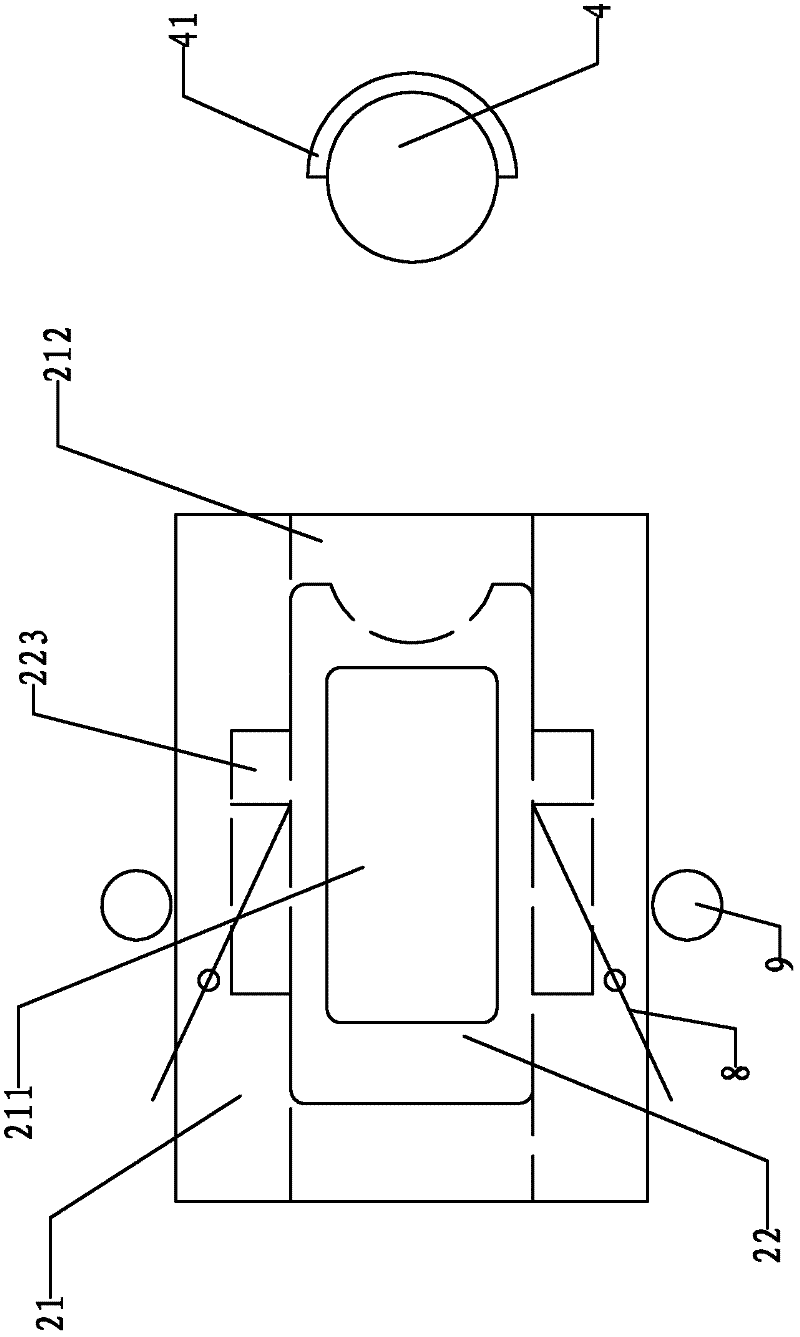

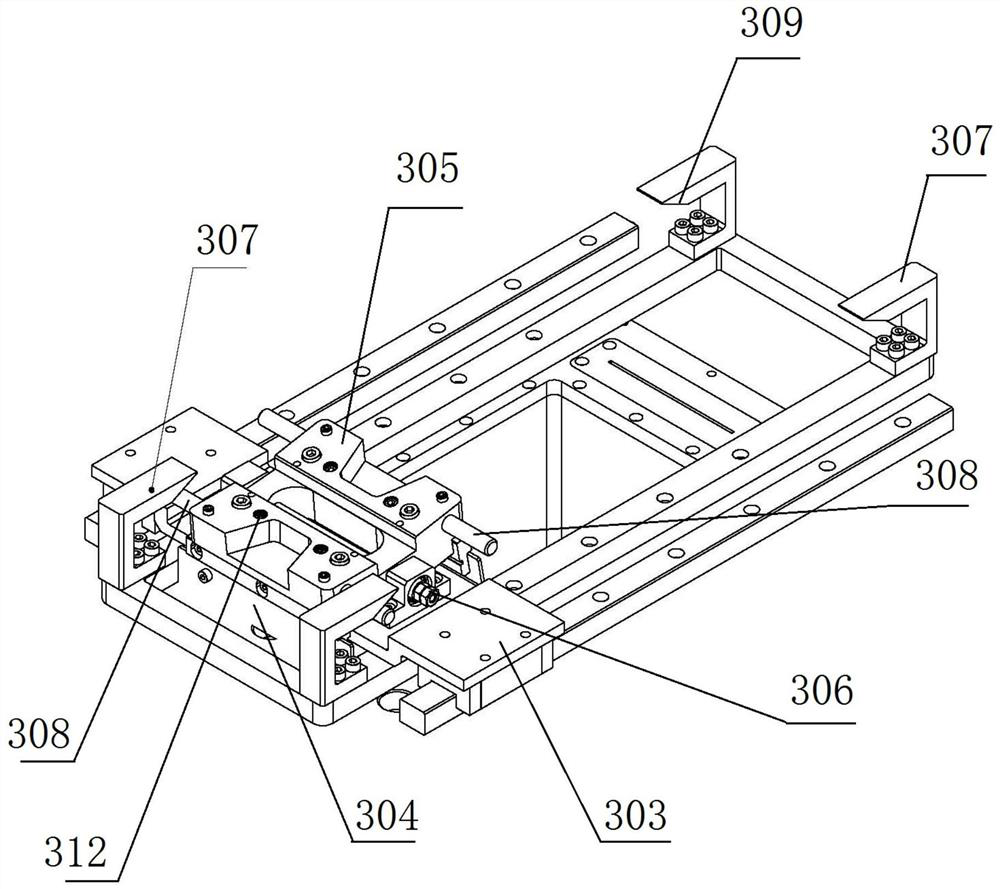

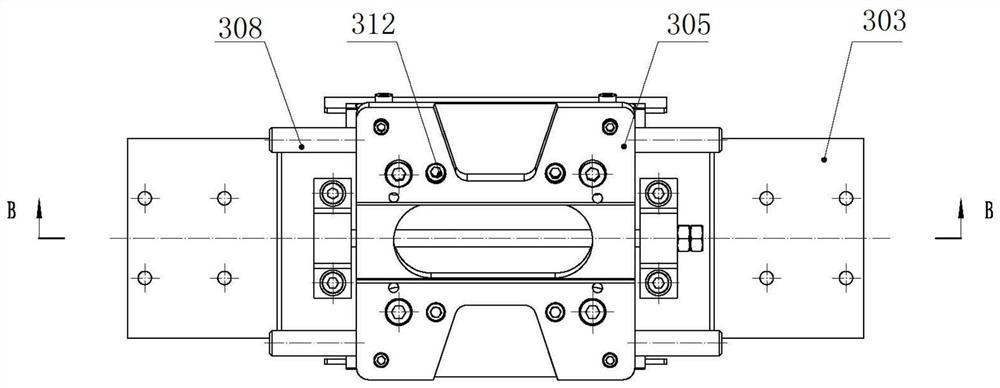

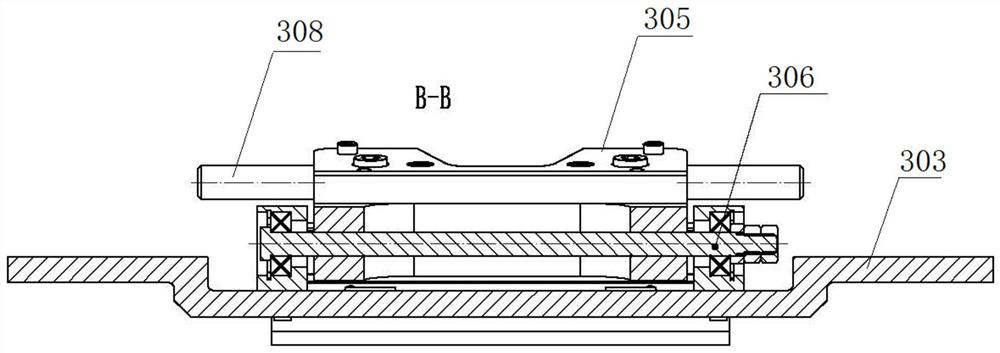

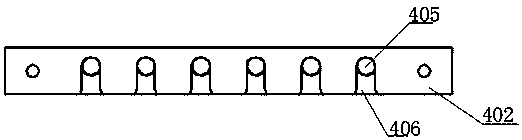

Feeding device of automatic assembly equipment for blades of blade lock

ActiveCN107617866ASolve the problem of automatic feedingHigh speedMetal working apparatusAutomatic test equipmentMechanical engineering

The invention relates to the field of lock production equipment, in particular to a feeding device of automatic assembly equipment for blades of a blade lock. The feeding device comprises a first feeding mechanism and a second feeding mechanism, the first feeding mechanism comprises a first conveying device, a transferring device and a turning device, and the second feeding mechanism comprises a second conveying device, a first vibration feeding disc and a mechanical arm. According to the feeding device, the first vibration feeding disc, the second conveying device and the mechanical arm are matched, the blades are contained into a blade box, the blade box is placed at the working position of assembly, and feeding of the blades is completed; the first conveying device, the transferring device and the turning device are matched, the directions of the two ends of a lock cylinder and corresponding directions of blade grooves in the lock cylinder are adjusted, then the lock cylinder is transferred to the working position of assembly in next step, and feeding of the lock cylinder is completed; and the manual working amount is reduced, the labor charges are reduced, cost is reduced, automatic production is completed, the lock cylinder assembly speed and quality are improved, and the feeding device is simple in mechanism and high in practicability.

Owner:扬州通扬化工设备有限公司

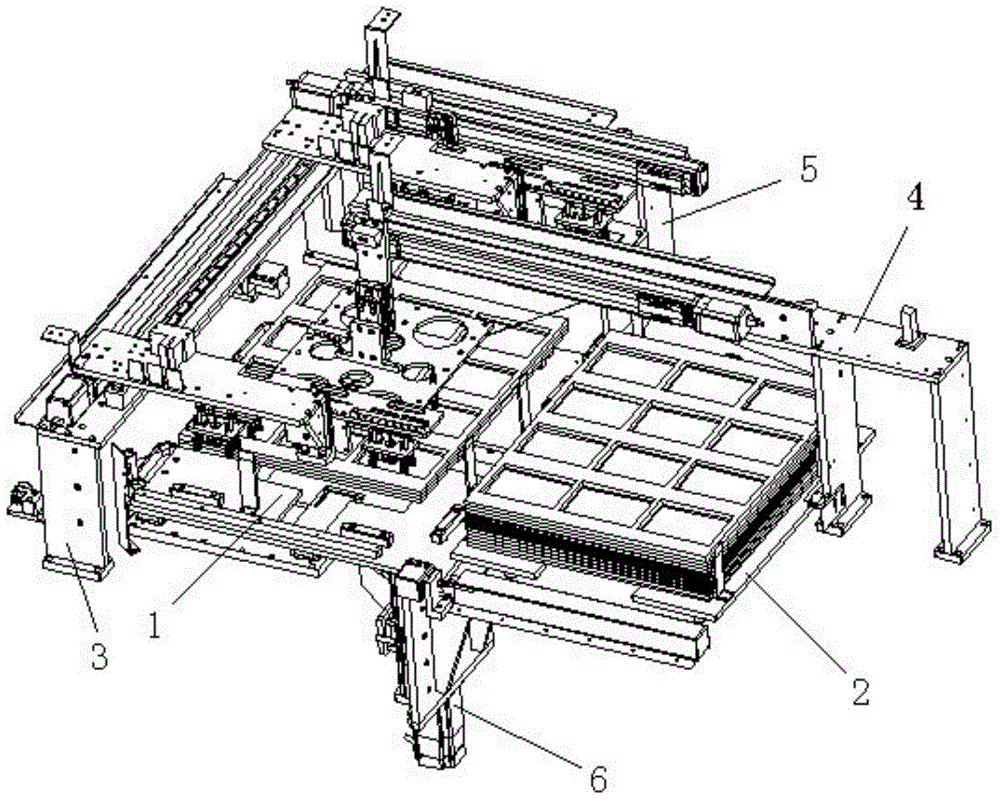

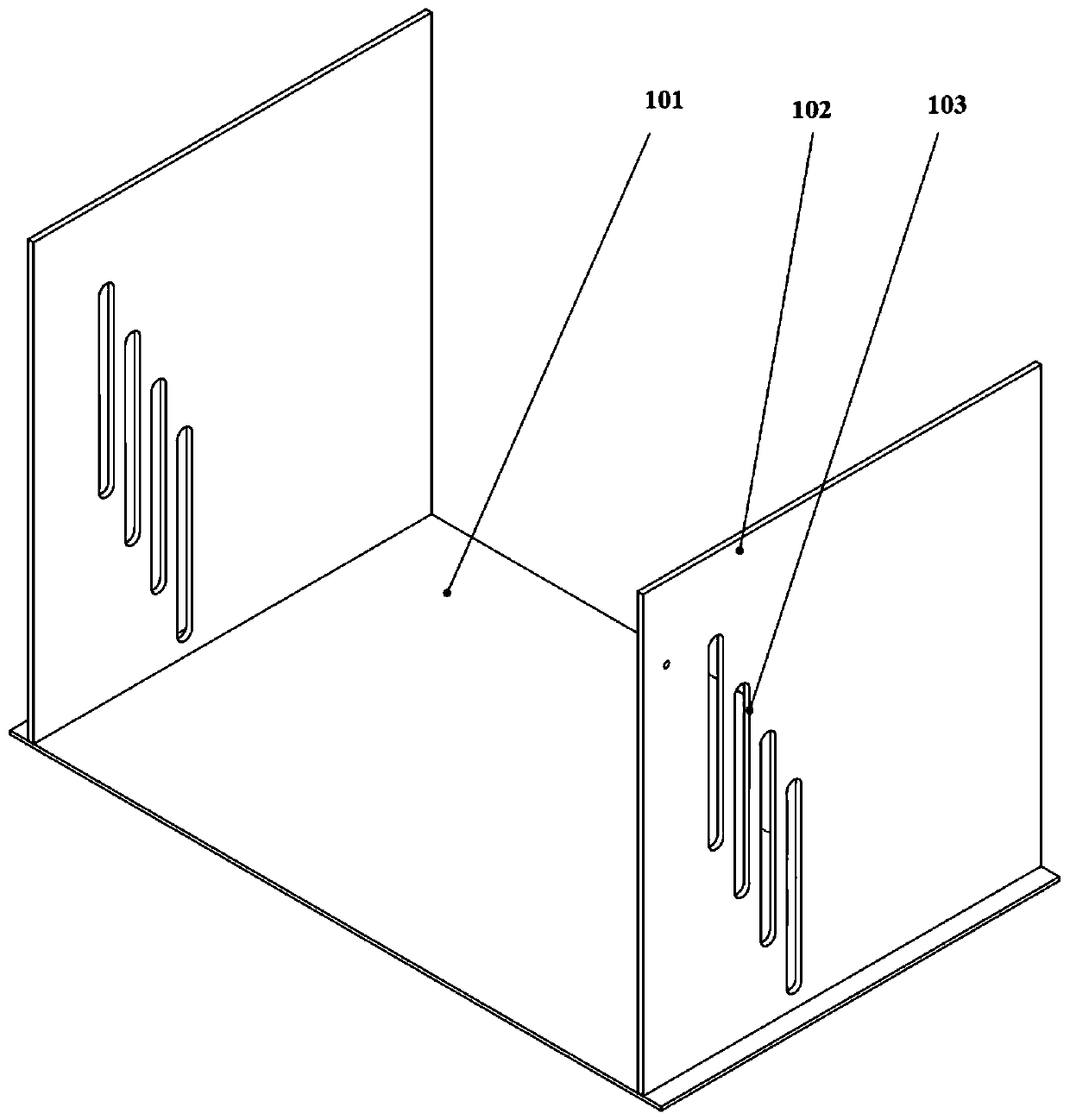

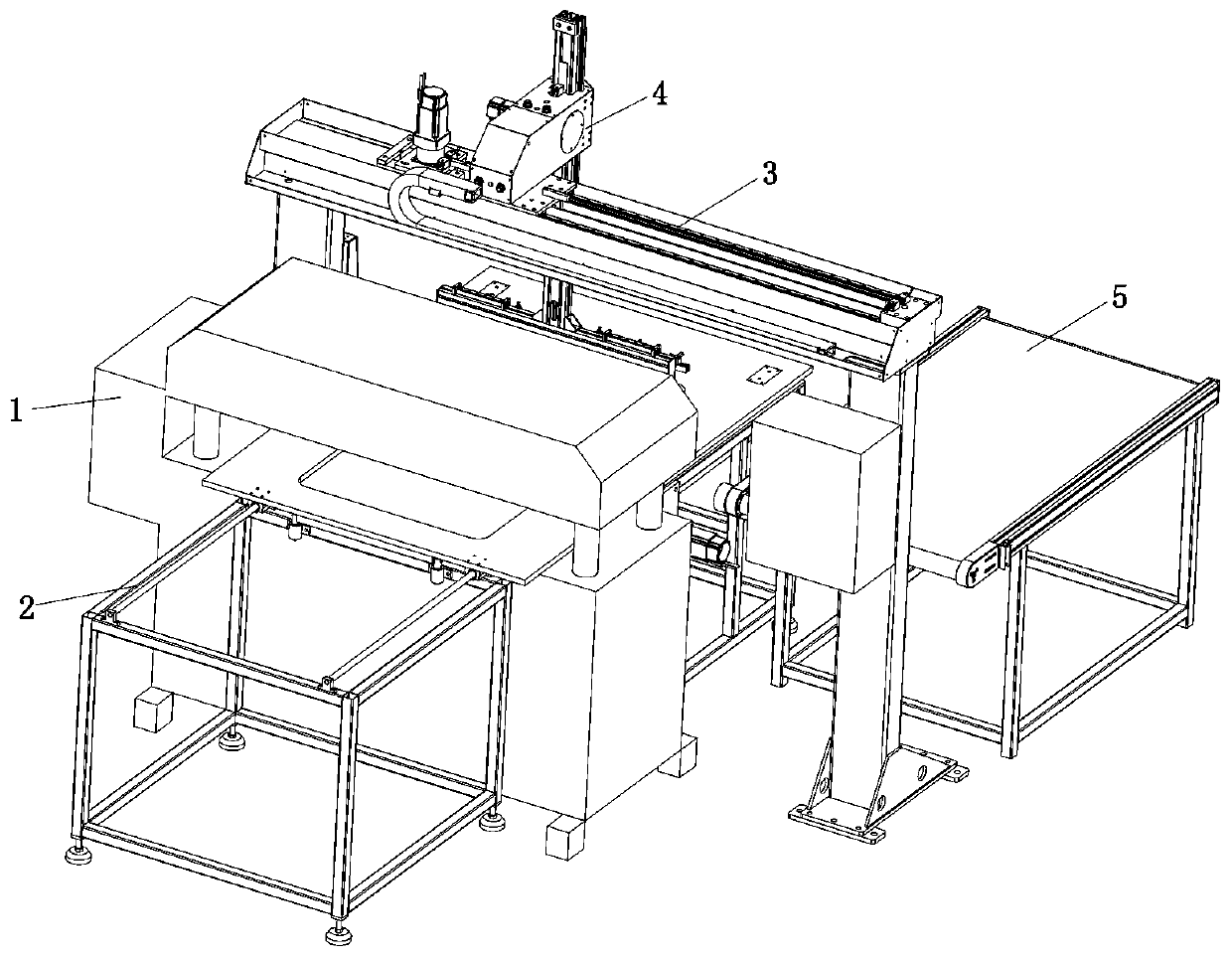

Automatic feeding device

ActiveCN104058243ASolve the problem of automatic feedingImprove feeding efficiencyConveyor partsManipulatorEngineering

The invention discloses an automatic feeding device. The feeding device comprises a feeding rack, as well as a feeding plate, a discharging plate, a longitudinal sliding bracket, a first transversal sliding bracket, a second transversal sliding bracket and a jacking device that are arranged on the feeding rack, wherein the feeding plate and the discharging plate are arranged on two sides of the feeding rack respectively; corresponding sliding rails and mechanical hand components arranged on the sliding rails are arranged on the longitudinal sliding bracket, the first transversal sliding bracket and the second transversal sliding bracket respectively; the jacking device is arranged on the lower side of the feeding plate. According to the feeding device, the feeding plate is adopted for feeding, the mechanical hand components on the longitudinal sliding bracket and the second transversal sliding bracket are adopted in a matched manner for material taking, and the mechanical hand component on the first transversal sliding bracket is adopted for removing empty battery trays and being matched with the jacking device, so that a plurality of battery trays can be piled up on the feeding plate at one time, and the feeding device is high in feeding efficiency and solves the problem of automatic feeding in a production line.

Owner:SUZHOU LING AUTOMATION EQUIP

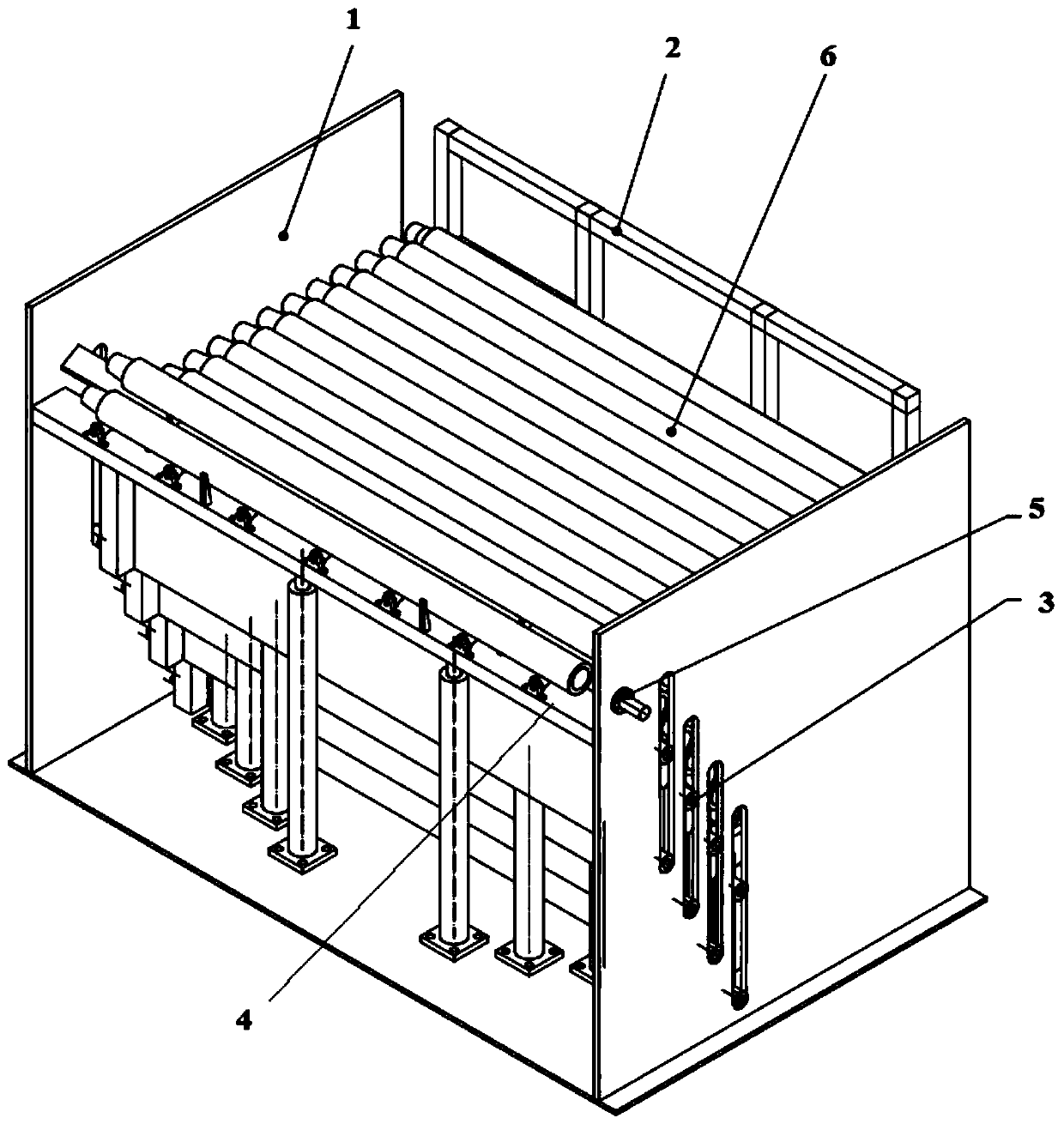

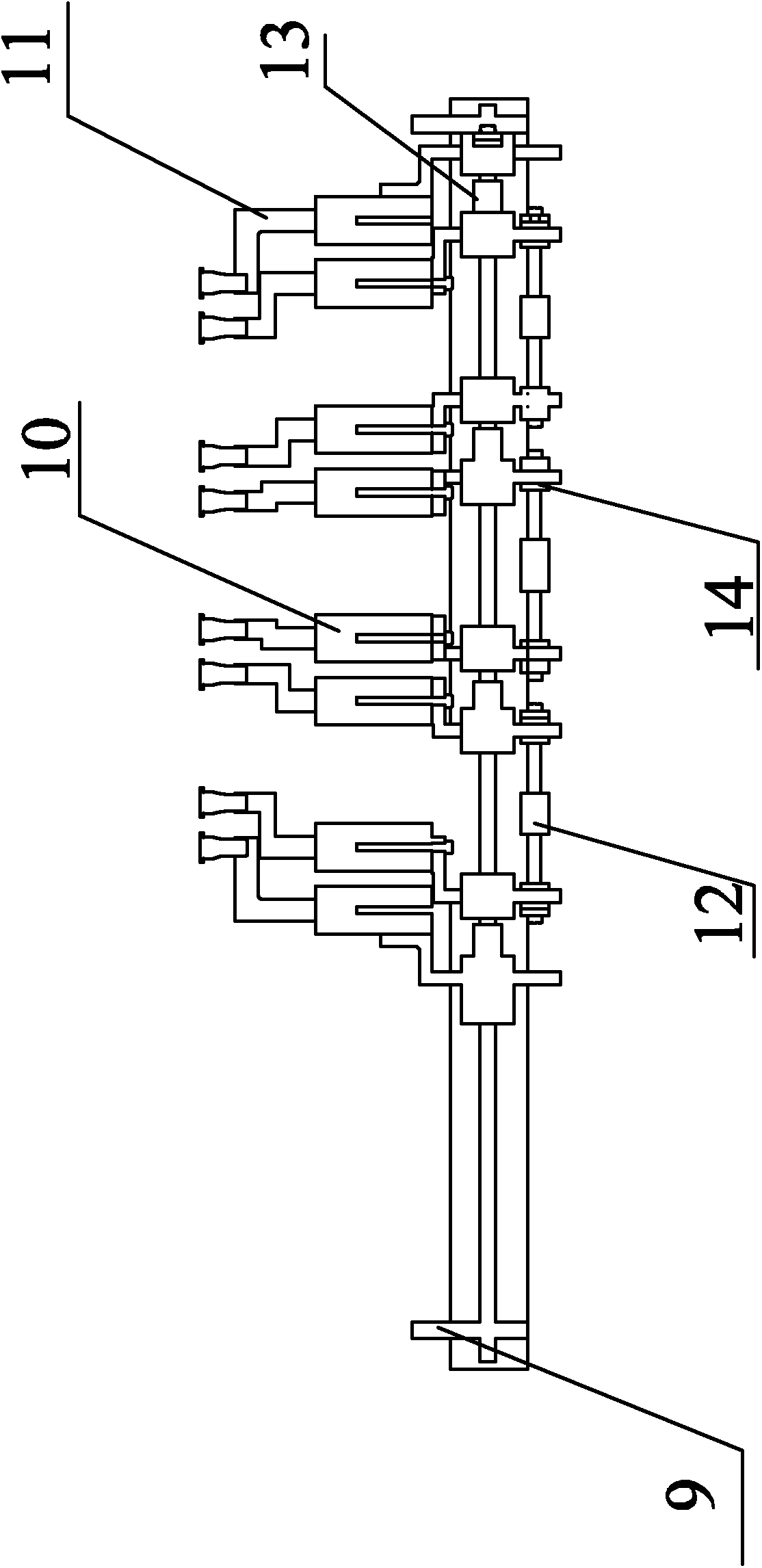

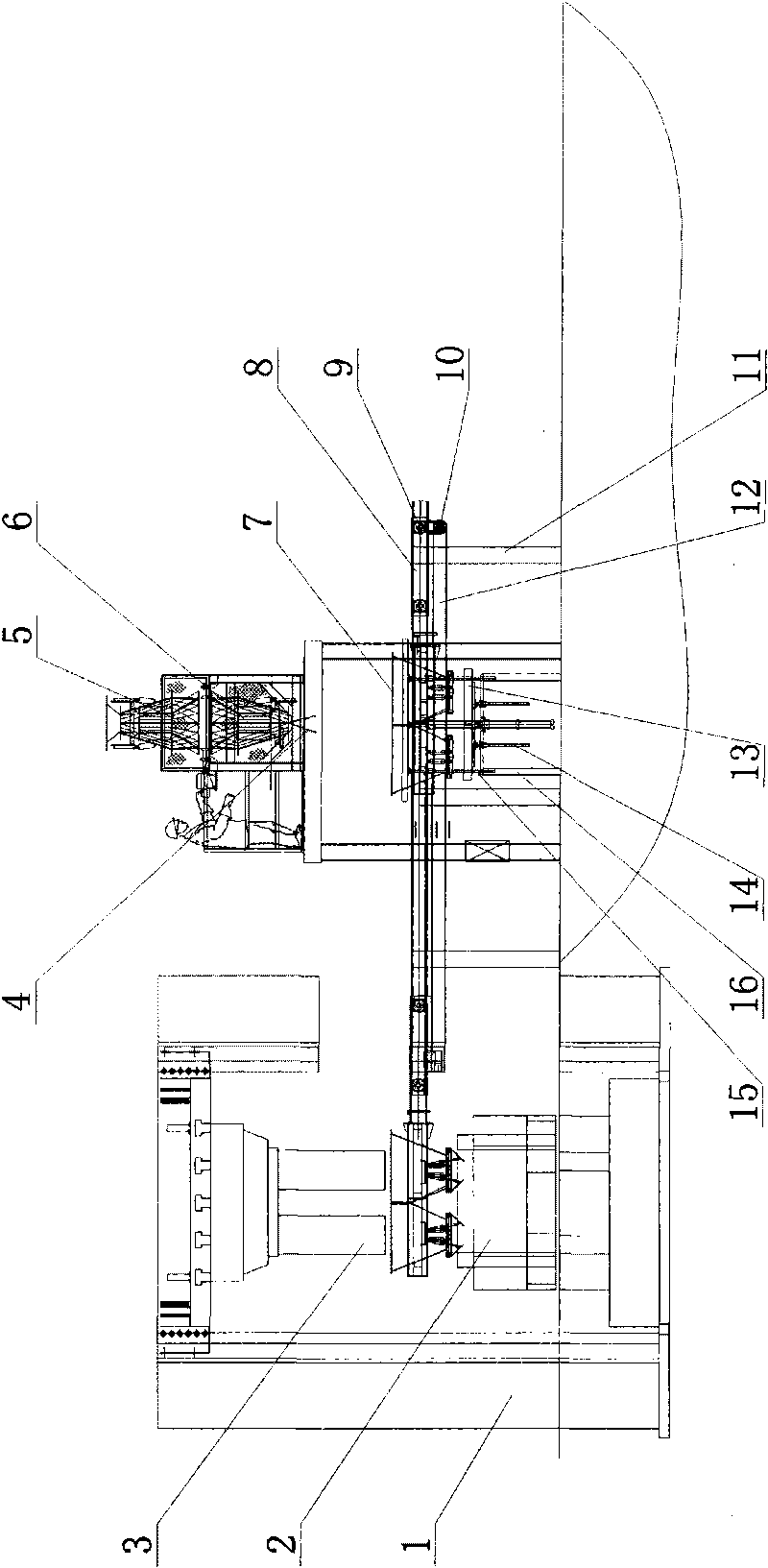

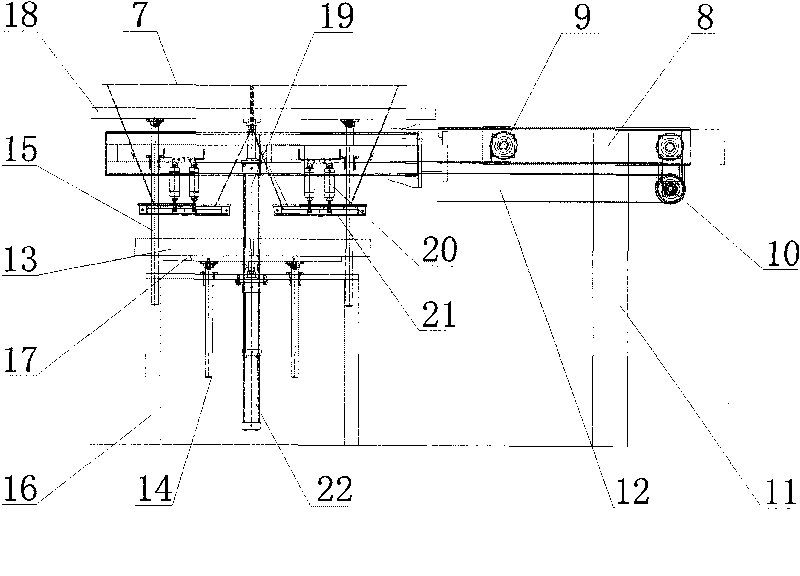

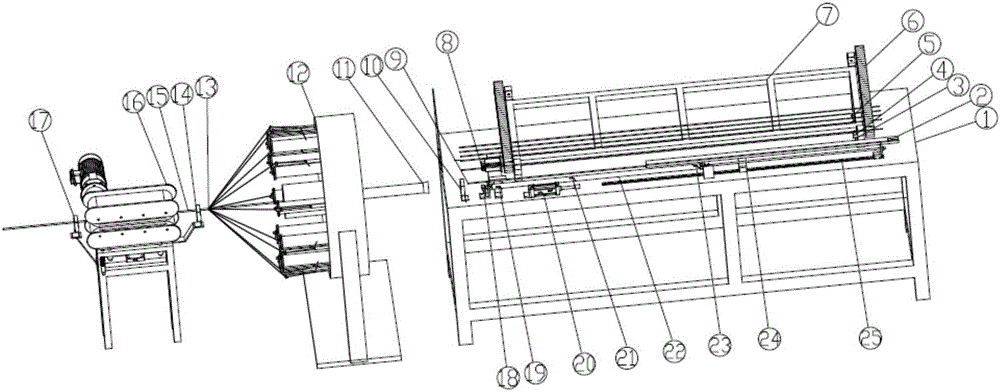

Drill rod machining automatic feeding system and method

ActiveCN111571289AReduce labor intensityReduce security risksAutomatic control devicesFeeding apparatusNumerical controlStructural engineering

The invention discloses a drill rod machining automatic feeding system and method. The system comprises a rack, a drill rod box, a stepped distributing device, a buffer device and a positioning device. Sensors are arranged on the parts. The system achieves the functions of drill rod automatic distributing and discharging functions during drill rod machining, the labor intensity of workers can be effectively reduced through a stable and reliable automatic feeding system, the production efficiency is improved, and meanwhile the safety risk probably caused during work of the workers is reduced. According to the method, through mutual cooperation and cooperative work of the graded stepped distributing device, the drill rod box, the positioning device, the buffer device and a sensor detection system, single drill rods are independently separated from the drill rod box and positioned, and distributing and discharging automation of the drill rods is achieved; and a multi-step automatic discharging method is adopted, so that the problem about automatic feeding generated when the long and heavy drill rods are subjected to numerical control machining on a machine tool is solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Automatic loading device applied to brake pad production

ActiveCN107720267ASolve the problem of automatic feedingImprove work efficiencyConveyor partsEngineeringLoading arm

The invention discloses an automatic loading device applied to brake pad production. The automatic loading device comprises a cross sliding table which is composed of a beam and a longitudinal beam insliding connection with the beam; a loading arm is arranged on the longitudinal beam in a sliding mode; a transverse drive mechanism is arranged between the beam and the longitudinal beam; a longitudinal drive mechanism is arranged between the longitudinal beam and the loading arm; the loading arm comprises a loading arm frame body; and a loading mechanism, a spraying mechanism, a flattening mechanism, a cleaning mechanism and a taking-placing mechanism are sequentially arranged in the loading arm frame body from rear to front. The device realizes automatic operation of a series of middle processes such as plate taking, cleaning, spraying, loading and steel backing, and solves the key automatic loading key in brake pad automatic production.

Owner:济南悦创液压机械制造有限公司

Automatic feeding and discharging device

ActiveCN104972345ASolve the problem of automatic feedingReduce Occupational InjuriesMetal working apparatusVertical planeCarriage

The invention provides an automatic feeding and discharging device. According to the device, a support is installed on a rack; a slide carriage is installed above the support; a buffer frame is installed at the middle section of a side wing of the slide carriage; a steering groove is connected to the tail end of the slide carriage; a thickness regulation plate is installed on a side wing of the steering groove, and the bottom surface of the thickness regulation plate is parallel with the vertical plane of the steering groove; a clamp is located under the steering groove, and a middle opening of the clamp right faces a bottom opening of the steering groove; a horizontal movement support is located under the steering groove; an unloading air cylinder is installed at the bottom of the horizontal movement support and fixedly connected with an unloading baffle in the horizontal movement support. The automatic feeding and discharging device is suitable for automatic feeding in the process of machining edge teeth of files and makes the files enter a machining position of a machine tool at a right posture.

Owner:中国兵器装备集团自动化研究所有限公司

T-shaped interface supply device for non-polyvinyl chloride (PVC) soft bag large transfusion production line

ActiveCN102320449AAchieve continuous operationSolve the problem of automatic feedingJigging conveyorsConveyor partsProduction linePolyvinyl chloride

The invention relates to an interface supply device for a soft bag large transfusion production line, in particular to a T-shaped interface supply device for a non-polyvinyl chloride (PVC) soft bag large transfusion production line, which comprises an oscillation hopper, a straight line slide way and a horizontal bracket, wherein the horizontal bracket is arranged under the straight line slide way in parallel; the straight line slide way is located diagonally above the oscillation hopper; and the technical key point lies in that: a clamping device is arranged under the straight line slide way, a straight line guide rail is arranged on the bottom of the clamping device, limiting frames are respectively arranged on the two ends of the straight line guide rail, clamping hands are arranged on the straight line guide rail, and a parallel gas claw is arranged on the upper end of each clamping hand. The continuous operation of the T-shaped interface production line can be realized, so that the automatic feeding problem of T-shaped interfaces is solved successfully and the development idea of a soft package transfusion manner is expanded through the T-shaped interface supply device for the PVC soft bag large transfusion production line provided by the invention.

Owner:SHINVA MEDICAL INSTR CO LTD

Buckle assembly equipment for lamp machining and use method thereof

ActiveCN113319561ASolve the problem of automatic feedingAchieve blockingMetal working apparatusGlass productionStructural engineeringLamp shell

The invention discloses buckle assembly equipment for lamp machining and a using method thereof. The buckle assembly equipment comprises a machining table; a conveying belt arranged on the machining table and used for conveying to-be-machined lamps; buckle conveying mechanisms arranged on two sides of the machining table; assembling mechanisms arranged on two sides of the conveying belt; and a positioning mechanism arranged on the machining table and used for fixing the to-be-machined lamps. By arranging the buckle conveying mechanism, disordered workpieces can be orderly and directionally arranged in order and conveyed, so that automatic feeding of the assembly equipment is achieved. A positioning plate is driven by a positioning mechanism and a vertical positioning air cylinder which are arranged on a portal frame to position a lamp shell in the vertical direction, a lateral positioning air cylinder drives a clamping plate to contract to position the lamp shell in the horizontal direction, the lamp shell is prevented from deviating in a buckle press-fitting process. By arranging the assembling mechanism, the buckles can be automatically press-fitted on two side edges of the lamp shell, so that the working efficiency is improved, and the labor intensity of workers is reduced.

Owner:郑州纬达自动化科技有限公司

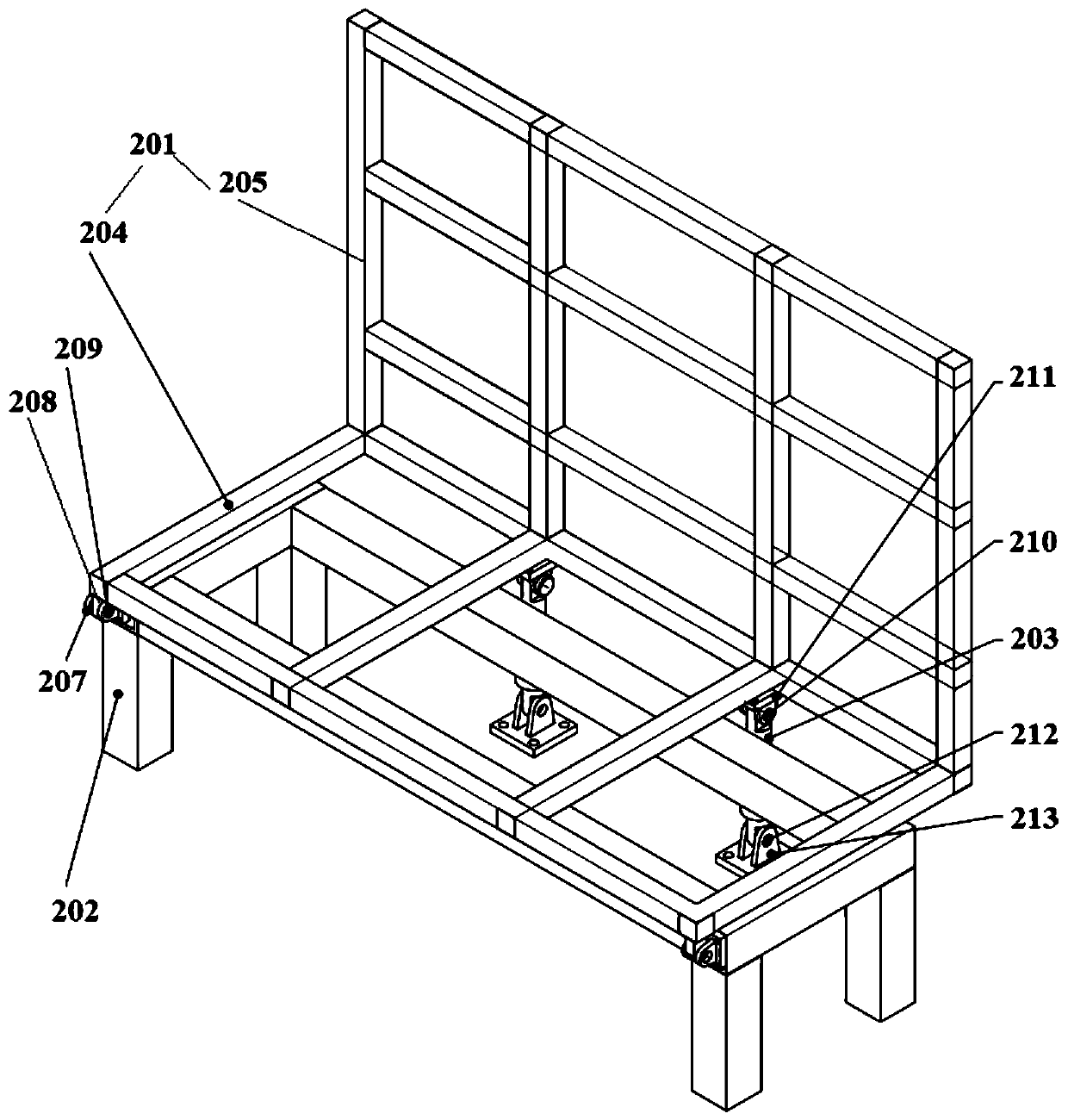

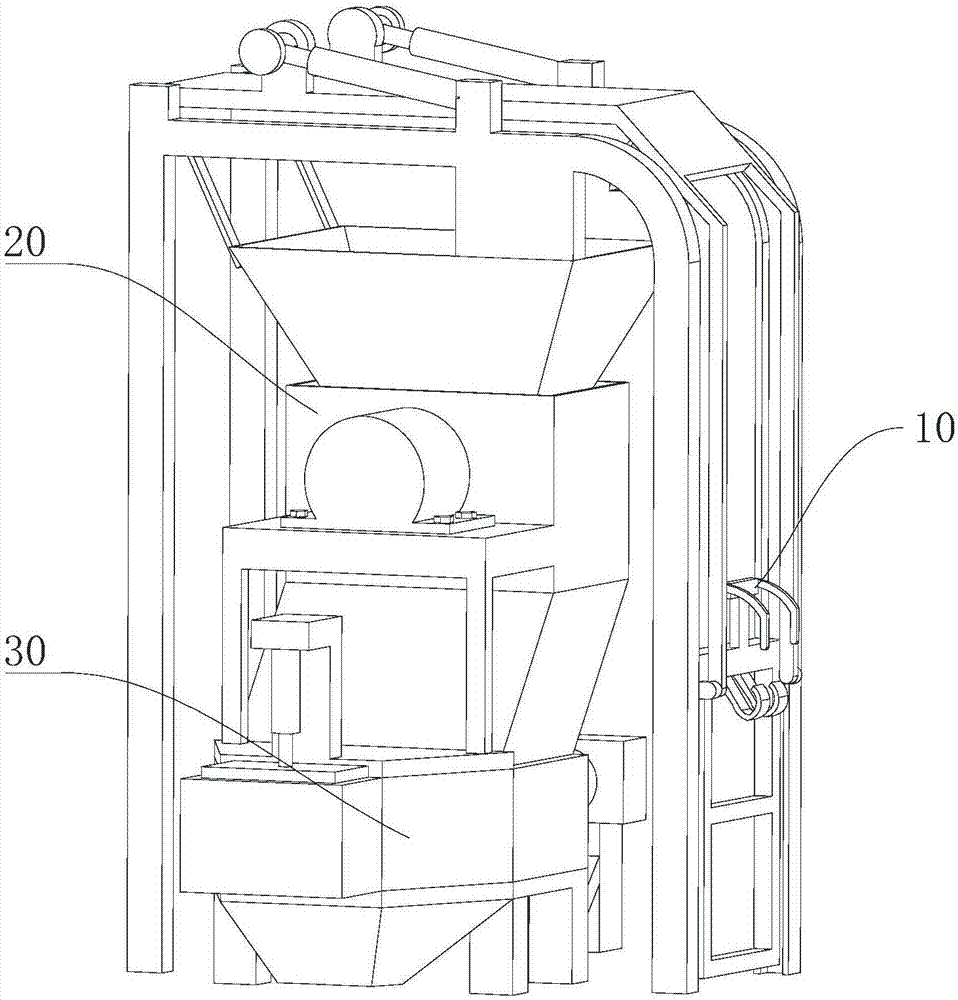

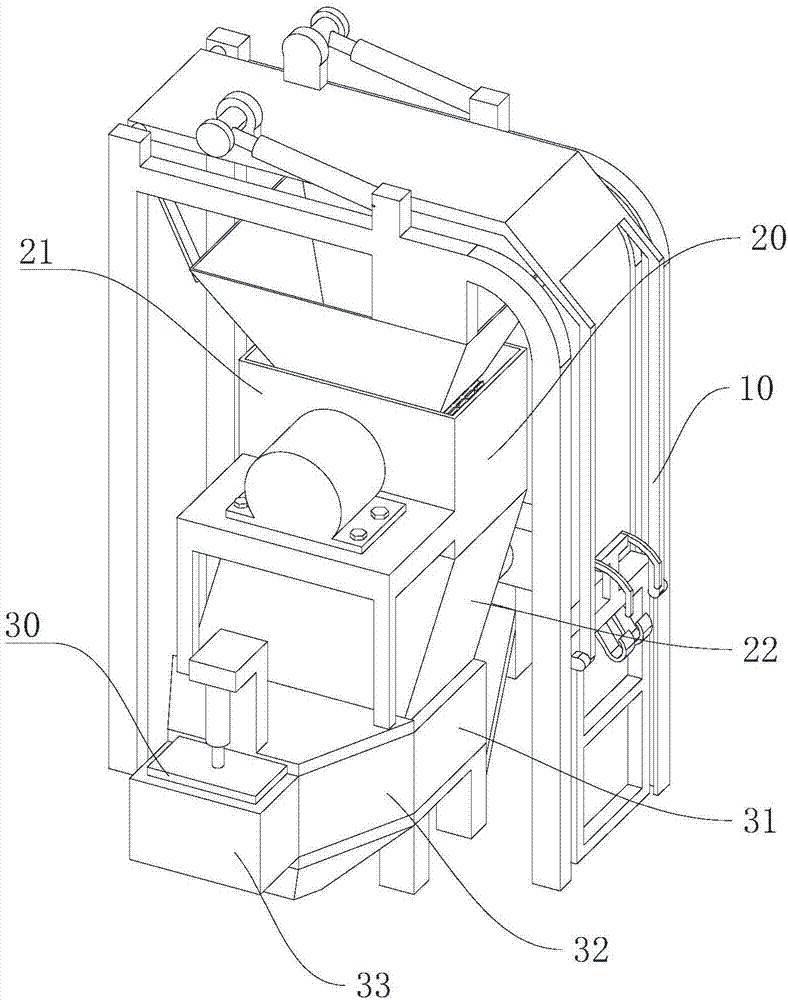

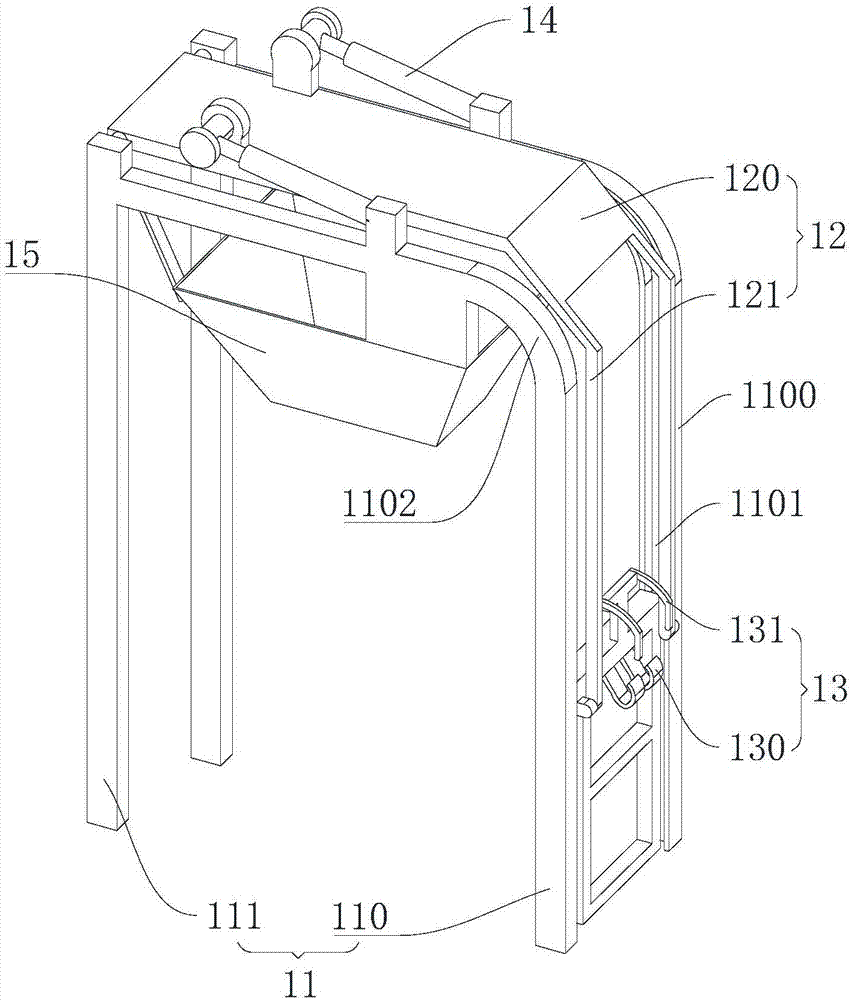

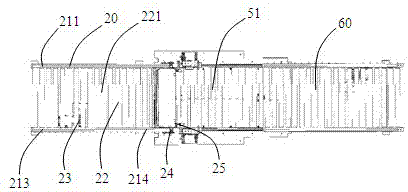

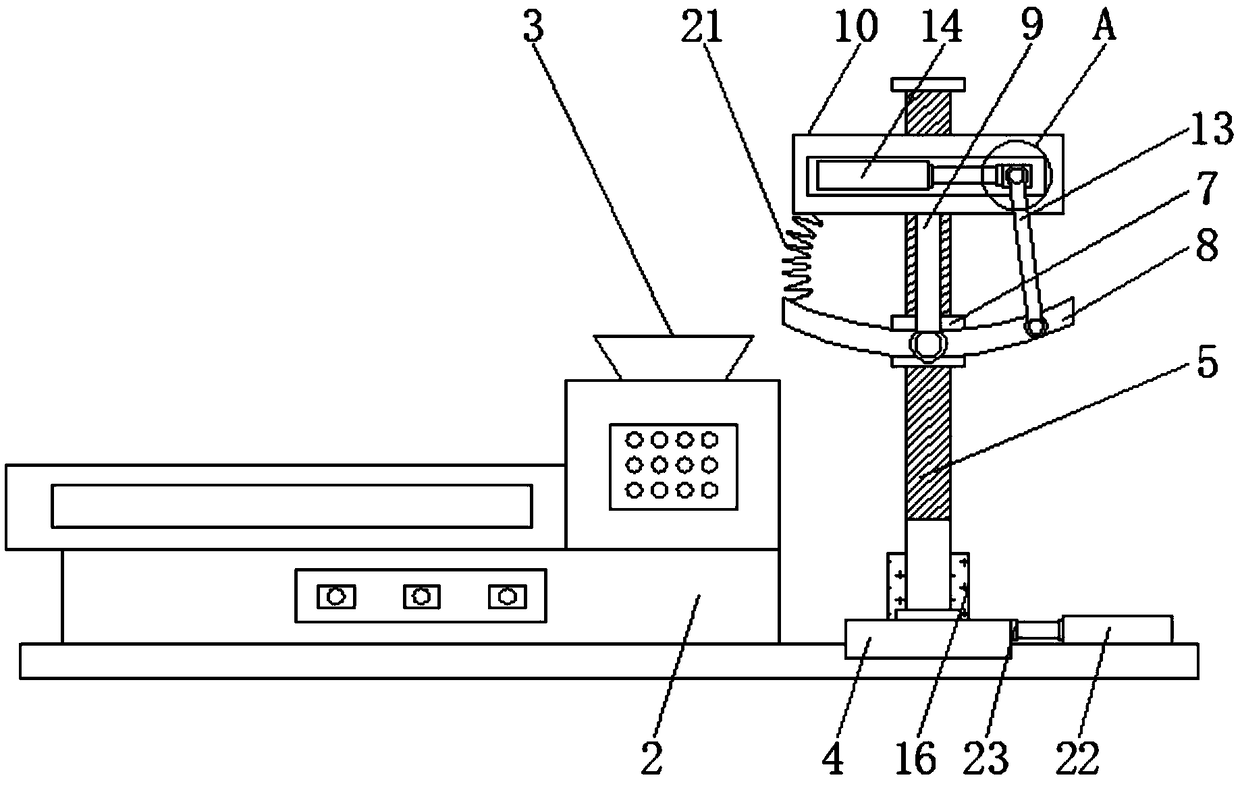

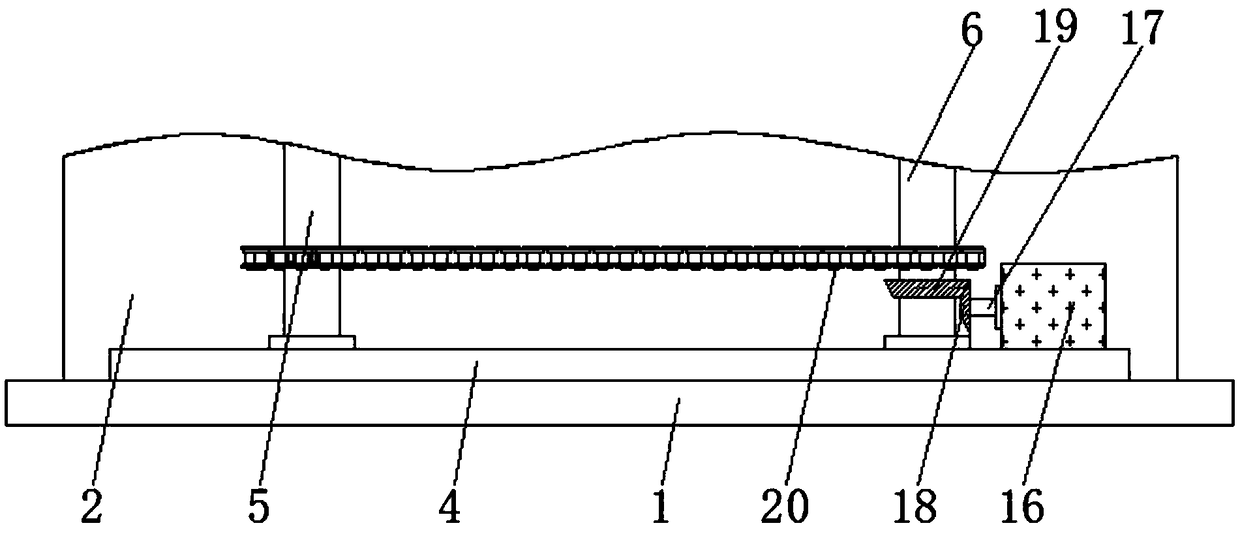

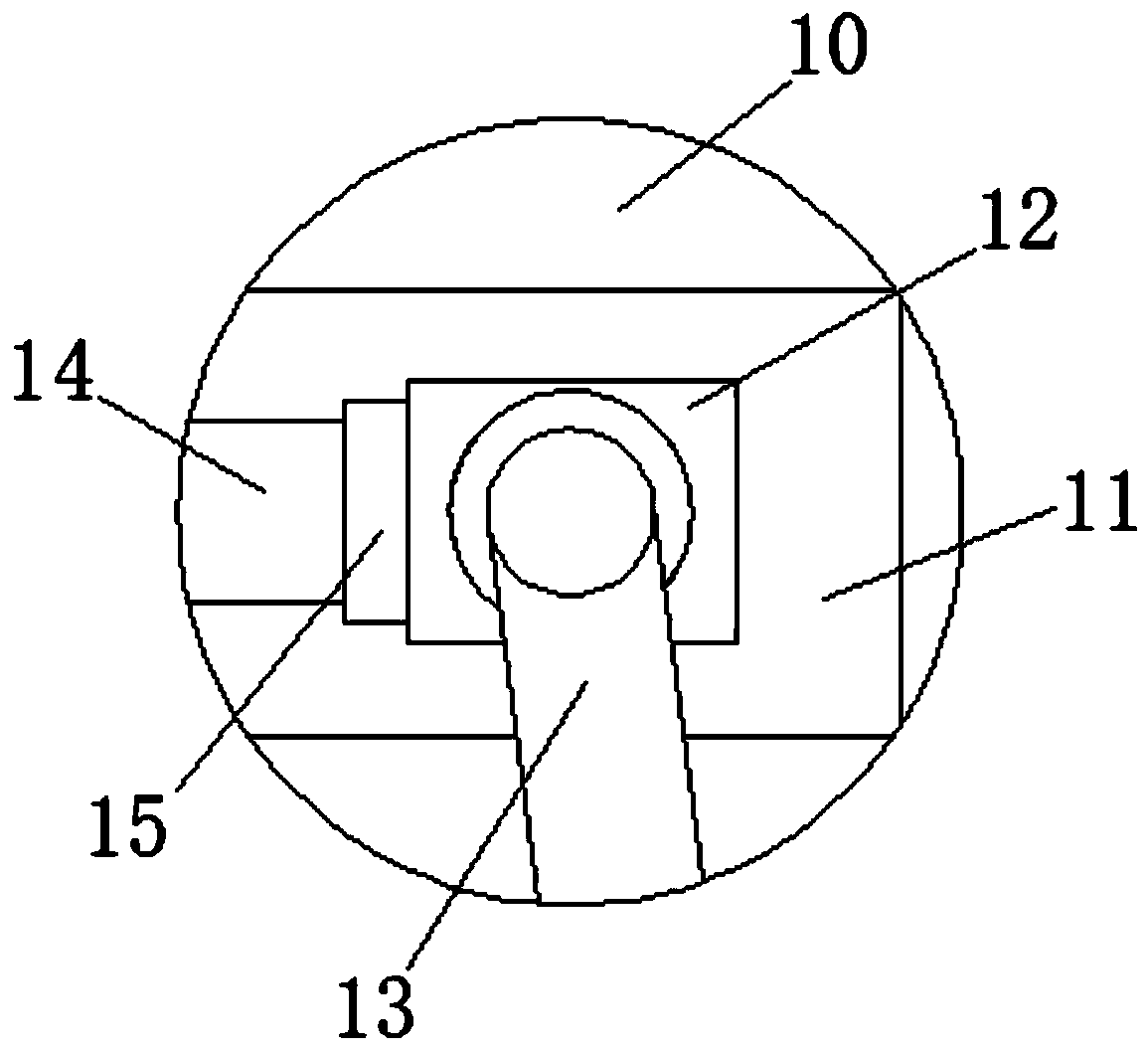

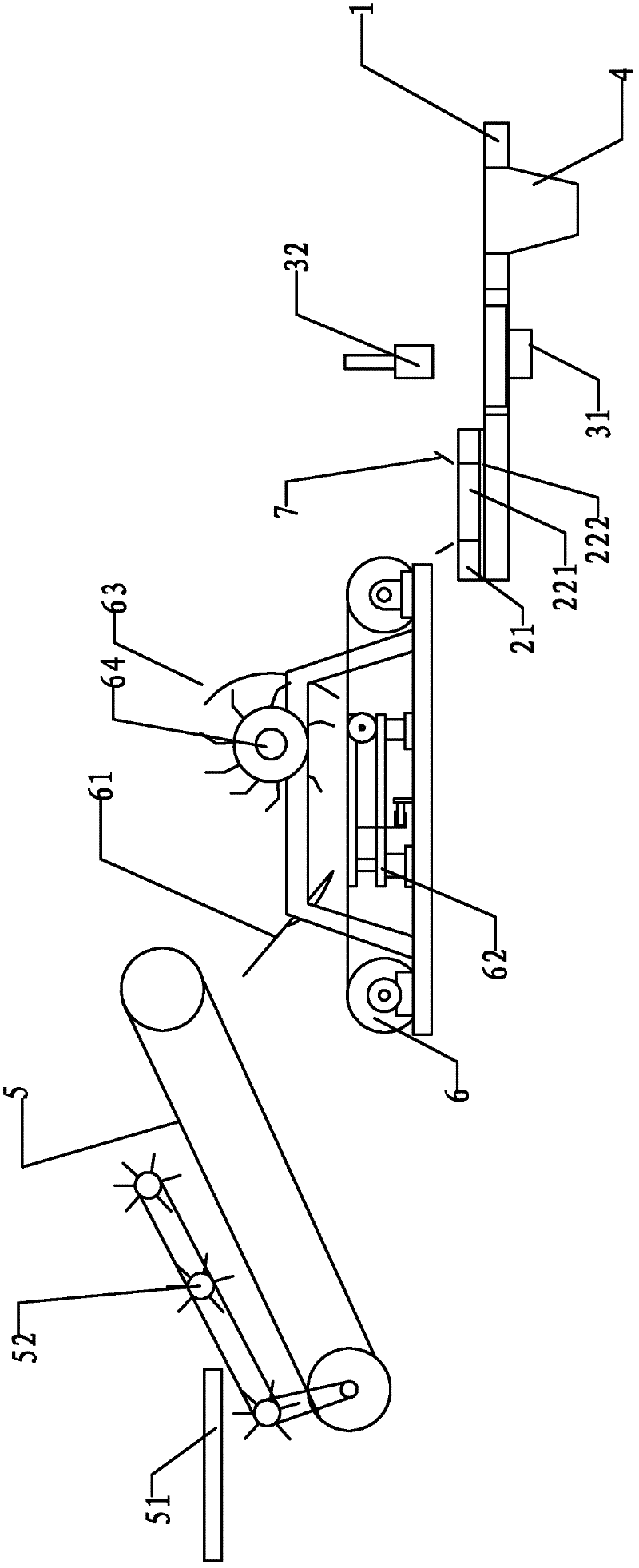

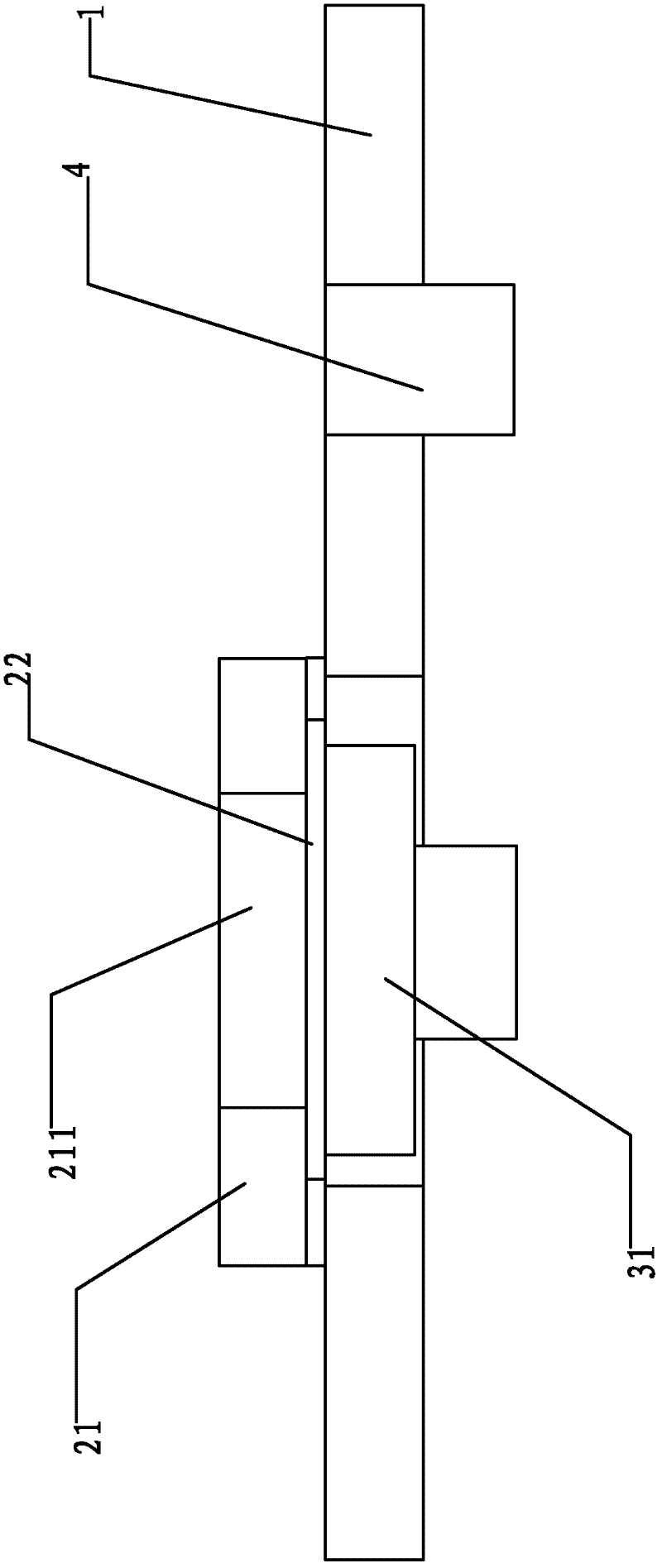

Intensive silkworm rearing apparatus

The invention discloses an intensive silkworm rearing apparatus, comprising: a frame; a rearing bed including a silkworm frame and a bottom plate, wherein a first rotary shaft is mounted below the bottom plate, the silkworm frame is arranged above the bottom plate in a manner of being erected along the length of the bottom plate, and the silkworm frame is composed of vertical rods and transverse rods that are staggered; a mulberry leaf conveying mechanism including a conveyer belt and a second rotary shaft, wherein the conveyer belt is mounted on the second rotary shaft and transversely rotates to convey mulberry leaves, and the second rotary shaft may axially rotate so that the conveyer belt turns down to pour the mulberry leaves; a cocoon picking mechanism including a guide rail and a cocoon comb, wherein the upper portion of the cocoon comb is in inserted fit with the guide rail, the lower portion of the cocoon comb is extended to the rearing bed, and the cocoon comb slides along the guide rail so as to peel off cocoons on the rearing bed; and a collection channel. The intensive silkworm rearing apparatus has the advantages that, for instance, silkworm yield is increased, disease damage is relieved, and the apparatus is suitable for intensive rearing.

Owner:NANJING ZHIQIAO AGRI CO LTD

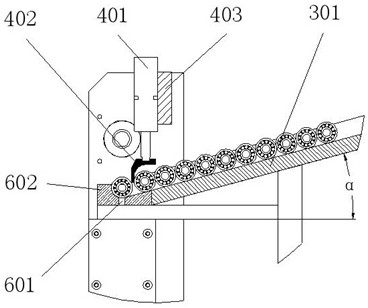

Automatic feeding device for small bearings

InactiveCN112338490ASave transfer structureThe feeding process is simpleMetal working apparatusConveyor partsRobot handControl engineering

The invention discloses an automatic feeding device for small bearings. The automatic feeding device comprises a frame body, a bearing storage bin, a limiting stopping mechanism, a driving connectingrod mechanism and a bearing transferring rail, the storage bin is arranged on the frame body, and the limiting stopping mechanism, the driving connecting rod mechanism and the bearing transferring rail are sequentially arranged above the storage bin from top to bottom and are coordinated with one another for transferring. The automatic feeding device has the advantages that bearings can be first orderly placed in the bearing storage bin in multiple rows and multiple columns through a mechanical arm or manual work, multi-batch feeding at a time used for automatic rotor assembly of one shift ormultiple shifts is realized, the bearings slide along a slope of the storage bin for feeding through the gravity of the bearings, the gravity of the bearings is fully utilized for generating movementkinetic energy, short-distance movement of the whole row of bearings is realized, and therefore a complex transferring structure is removed, and the feeding procedure is simplified.

Owner:FGLS ELECTRIC CO LTD

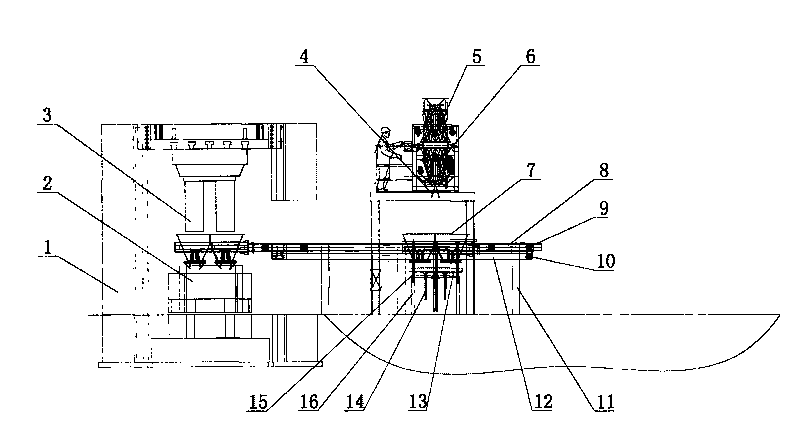

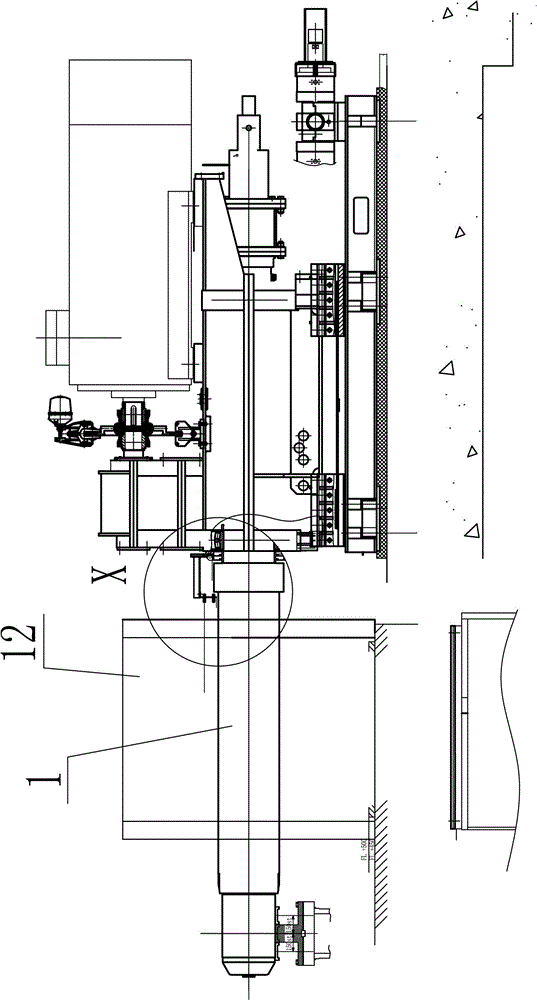

Automatic feeding device of zirconium electrode hydraulic machine

InactiveCN101758644ASolve the problem of automatic feedingIncrease productivityPressesHydraulic cylinderEngineering

The invention relates to an automatic feeding device of a zirconium electrode hydraulic machine, which is characterized in that: a rack is arranged beside a hydraulic machine, a guide rail is arranged on the rack, a moving trolley, rolling wheels of the moving trolley and a speed reducing device which drives the rolling wheels are arranged on the guide rail, a frame supporting plate is arranged on the trolley, two rectangle hoppers and a hopper lifting mechanism thereof are arranged side by side in the middle of the supporting plate, an opening sealing plate and a hydraulic cylinder are arranged at the bottom part of the hopper, an electronic weighing device of the hopper is arranged in the rack, the speed reducing device, the hydraulic cylinder, the lifting mechanism and the electronic weighing device of the hopper are all controlled by a PLC system; therefore, zirconium material is automatically fed into a hydraulic machine mould by the hopper of the trolley and the electronic weighing device, thereby solving the automatic feeding problem, the feeding is fast and accurate, and the production efficiency is greatly increased.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Environment-friendly garbage recycling and treating device

InactiveCN107363079ASolve the problem of automatic feedingSolution volumeSolid waste disposalGrain treatmentsMoistureSanitation

The invention provides an environment-friendly garbage recovery treatment device, which relates to the field of environmental protection equipment and includes a feeding mechanism, a crushing mechanism and a pressing mechanism. The crushing mechanism is arranged between the feeding mechanism and the pressing mechanism. The crushing mechanism includes a crushing bin and a transition The pressing mechanism includes the feeding bin, the pressing bin and the discharging bin. The feeding mechanism is used to transport the garbage to the crushing bin. One end of the transition bin is connected with the crushing bin, and the other end of the transition bin is connected with the feeding bin. The pressing bin It is set between the feed bin and the discharge bin. This device integrates feeding, crushing and compression, which can effectively solve the problems of automatic feeding, large volume and low transportation efficiency of garbage. The feeding process will not cause garbage leakage, which is environmentally friendly and hygienic. When the garbage is compressed, the garbage and the water in it can be separated in an orderly manner, which can not only greatly reduce the volume of the garbage, but also reduce the weight of the solid garbage and improve the efficiency of shipment.

Owner:CHENGDU HENGLIDA TECH

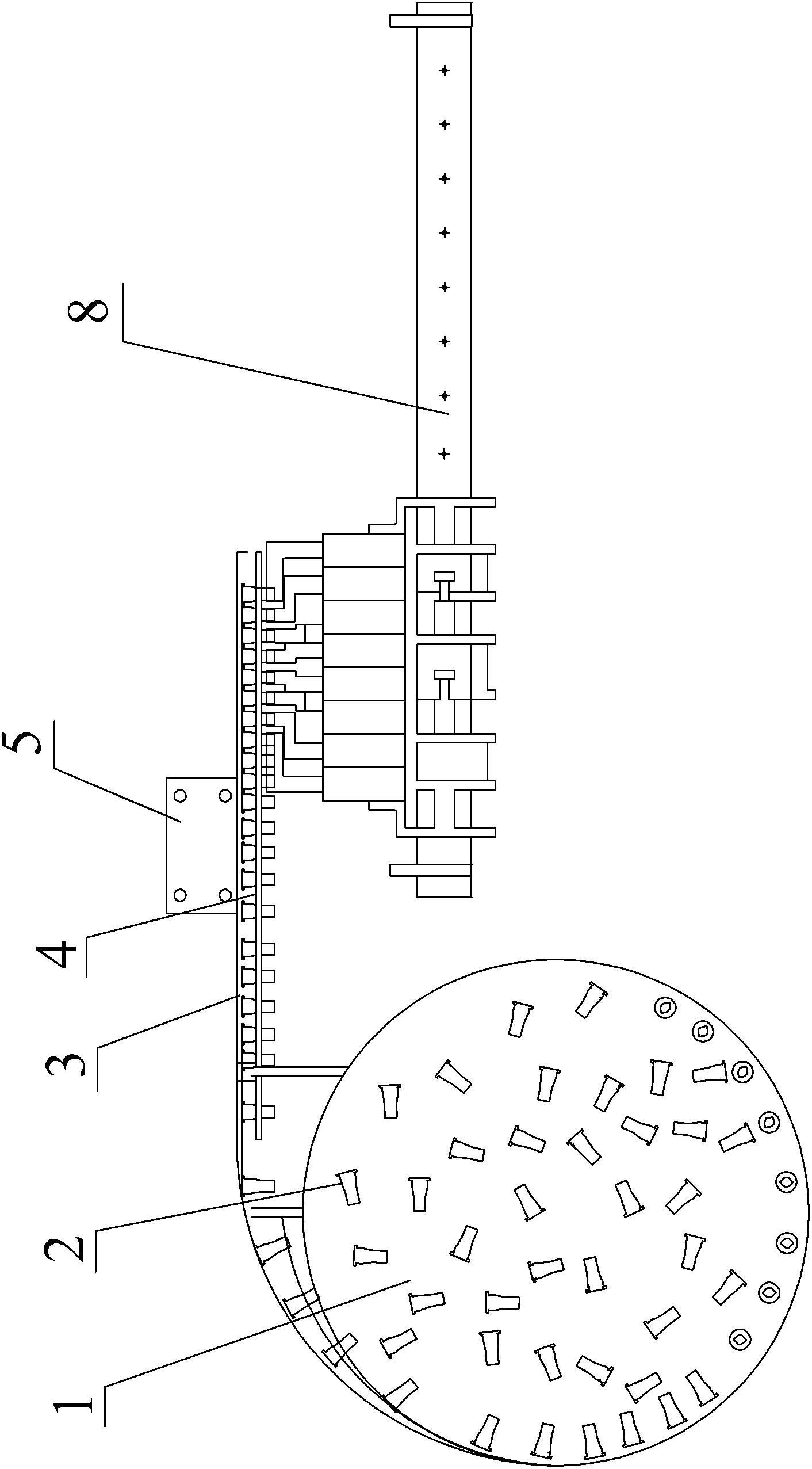

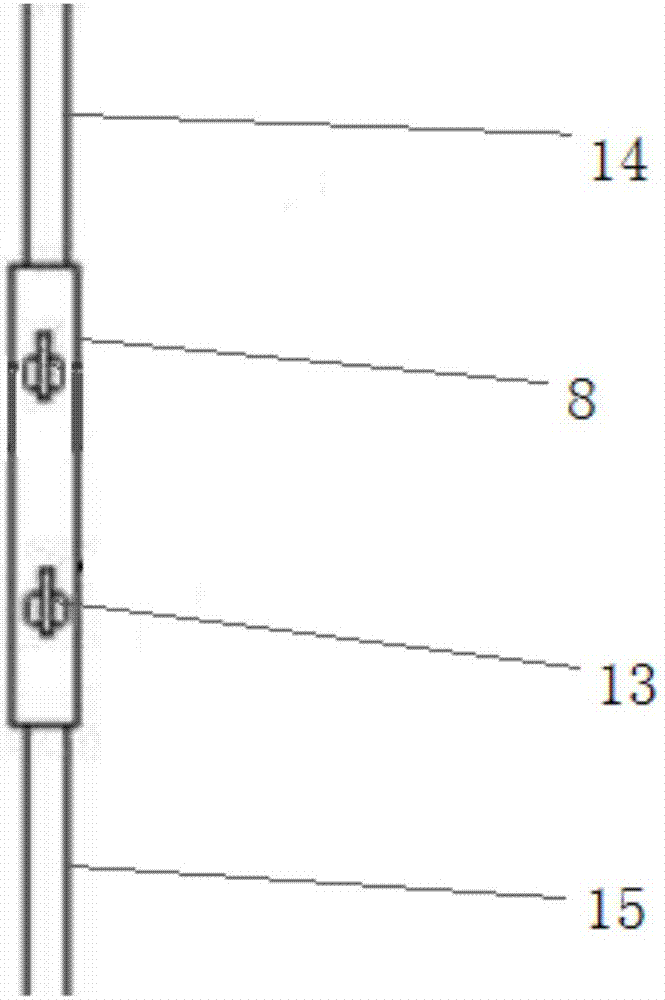

Crystalline silicon clamp feeding system

InactiveCN103922114ASolve the problem of automatic feedingIncrease productivityConveyor partsEngineeringCrystalline silicon

The invention discloses a crystalline silicon clamp feeding system. The crystalline silicon clamp feeding system comprises a support, a conveying portion, a power system, a position sensor and a blocking air cylinder, wherein the conveying portion is mounted on the support, the power system provides power for the conveying portion, and the position sensor is mounted at one end of the support. Compared with feeding systems in the prior art, the crystalline silicon clamp feeding system has the advantages that the crystalline silicon clamp automatic feeding during large-scale automatic production of silicon wafers can be achieved so that increase of producing efficiency and reduction of producing costs of the silicon wafers are facilitated.

Owner:SIP GOLDWAY TECH

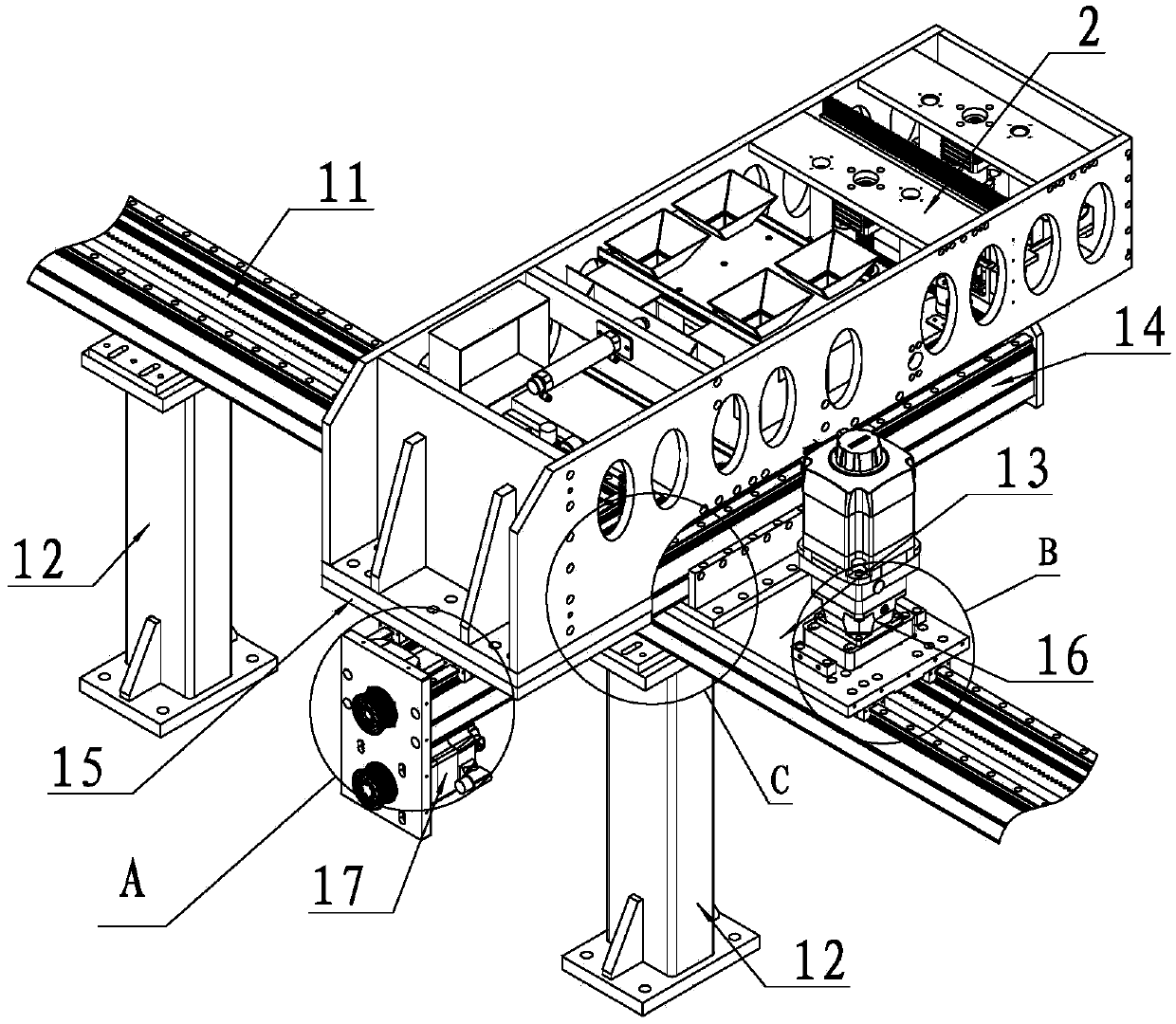

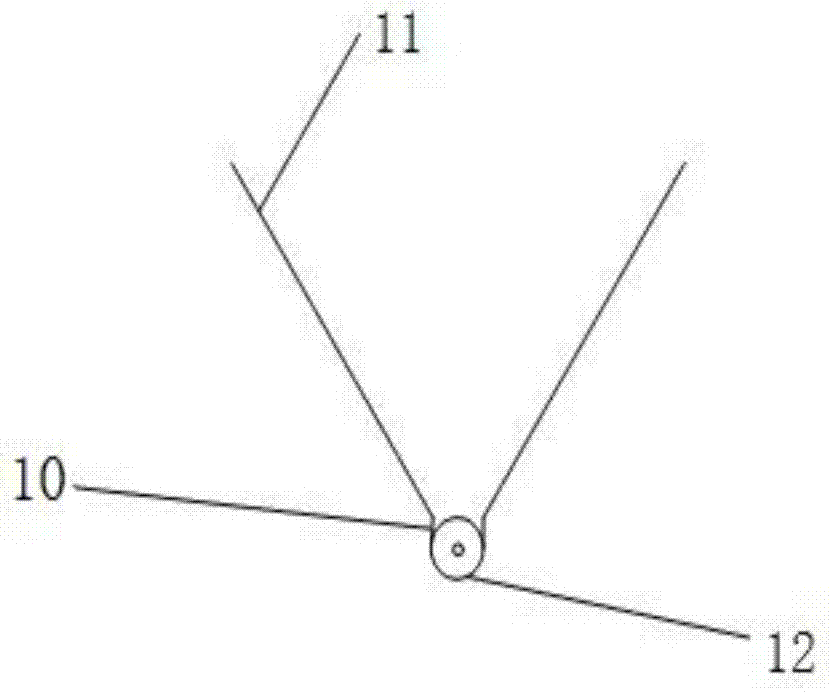

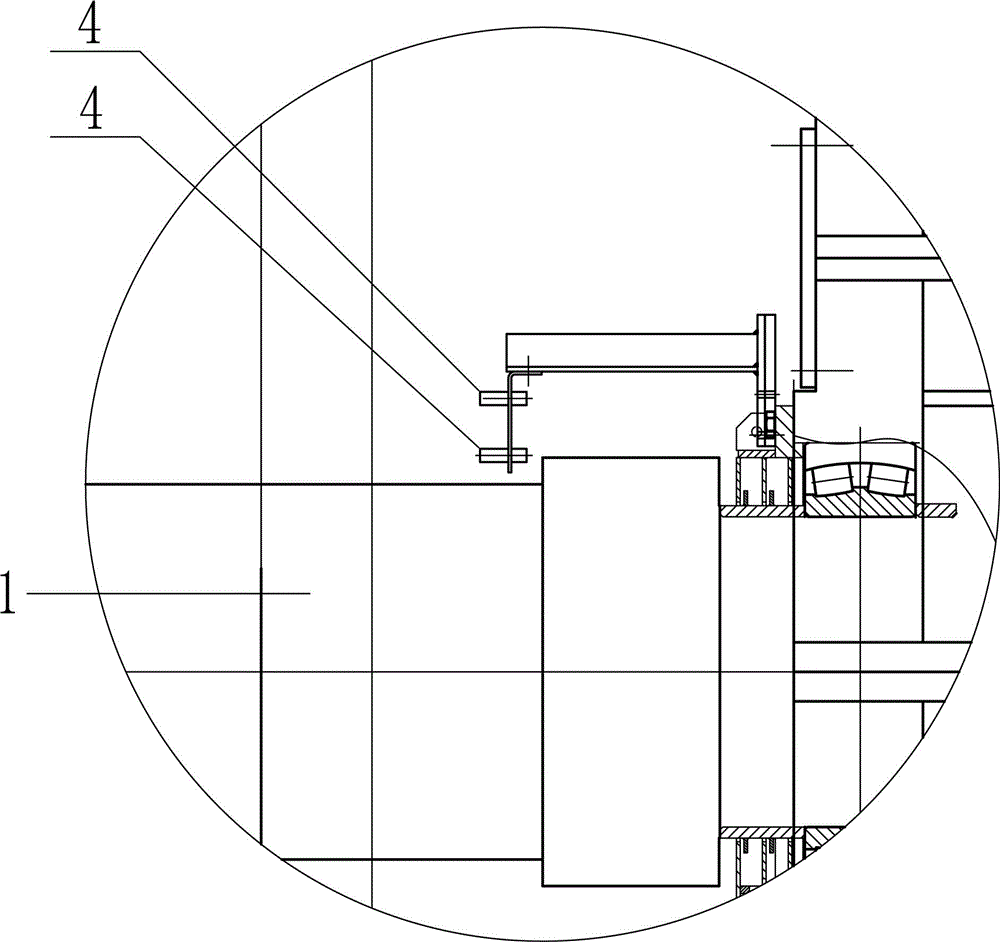

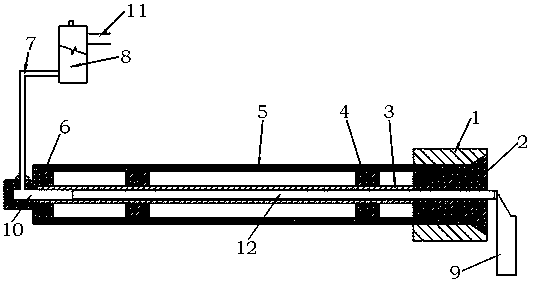

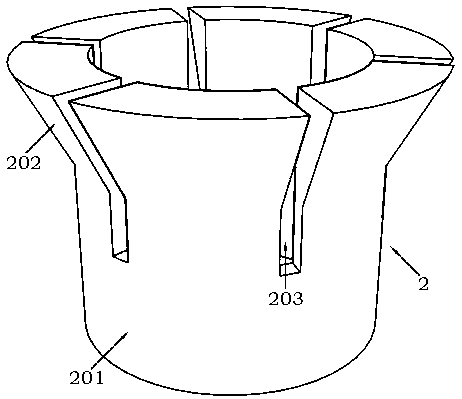

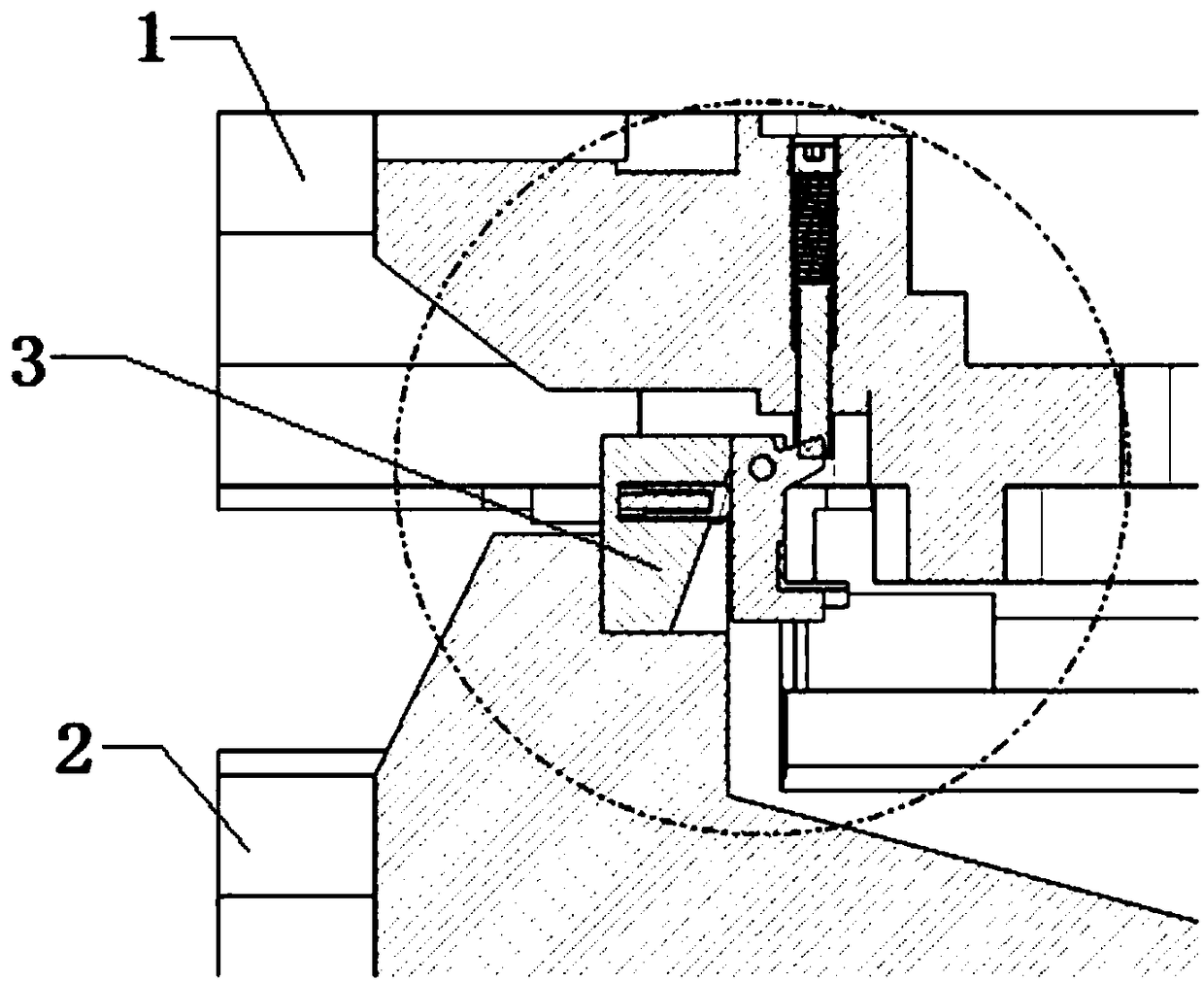

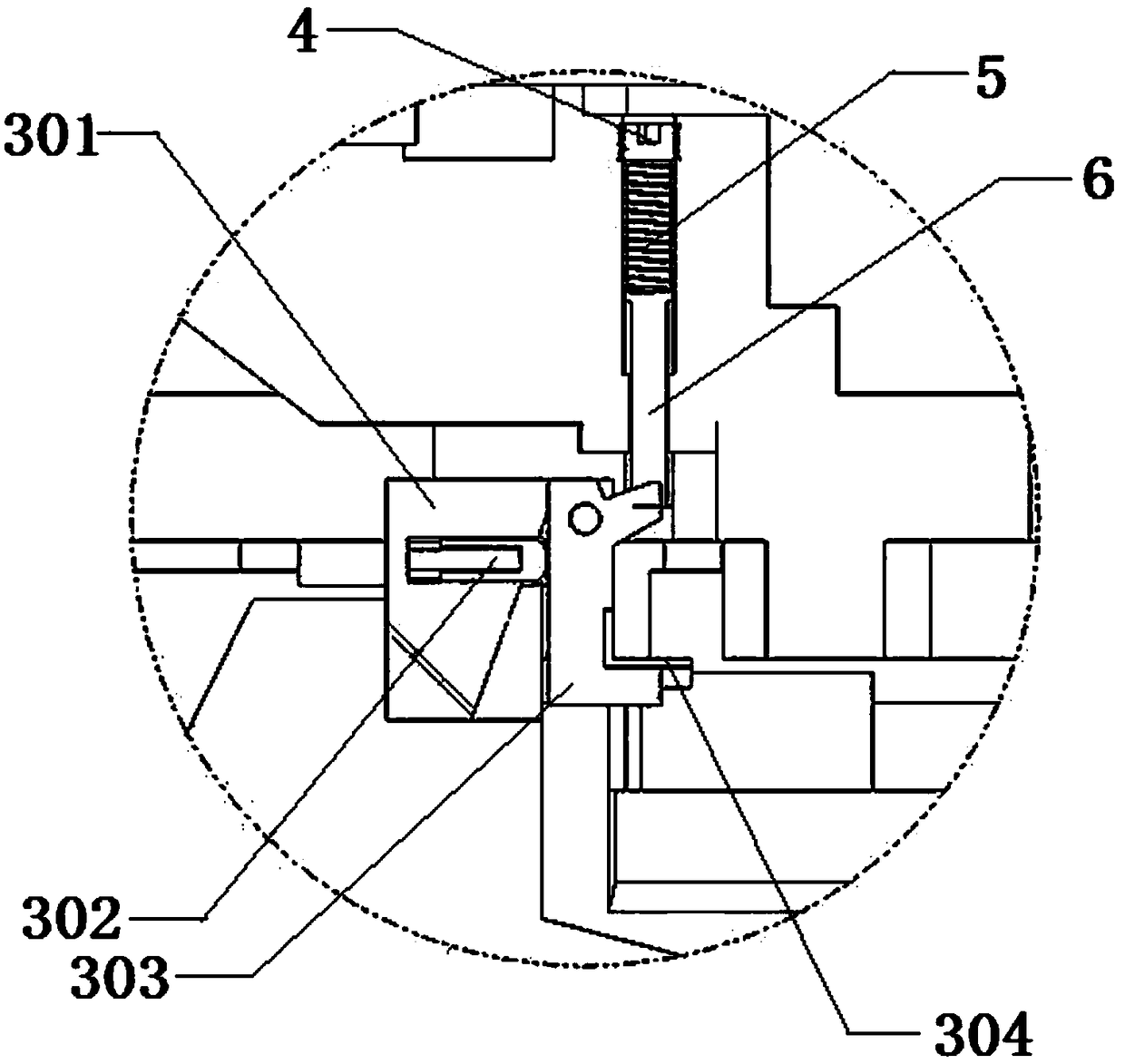

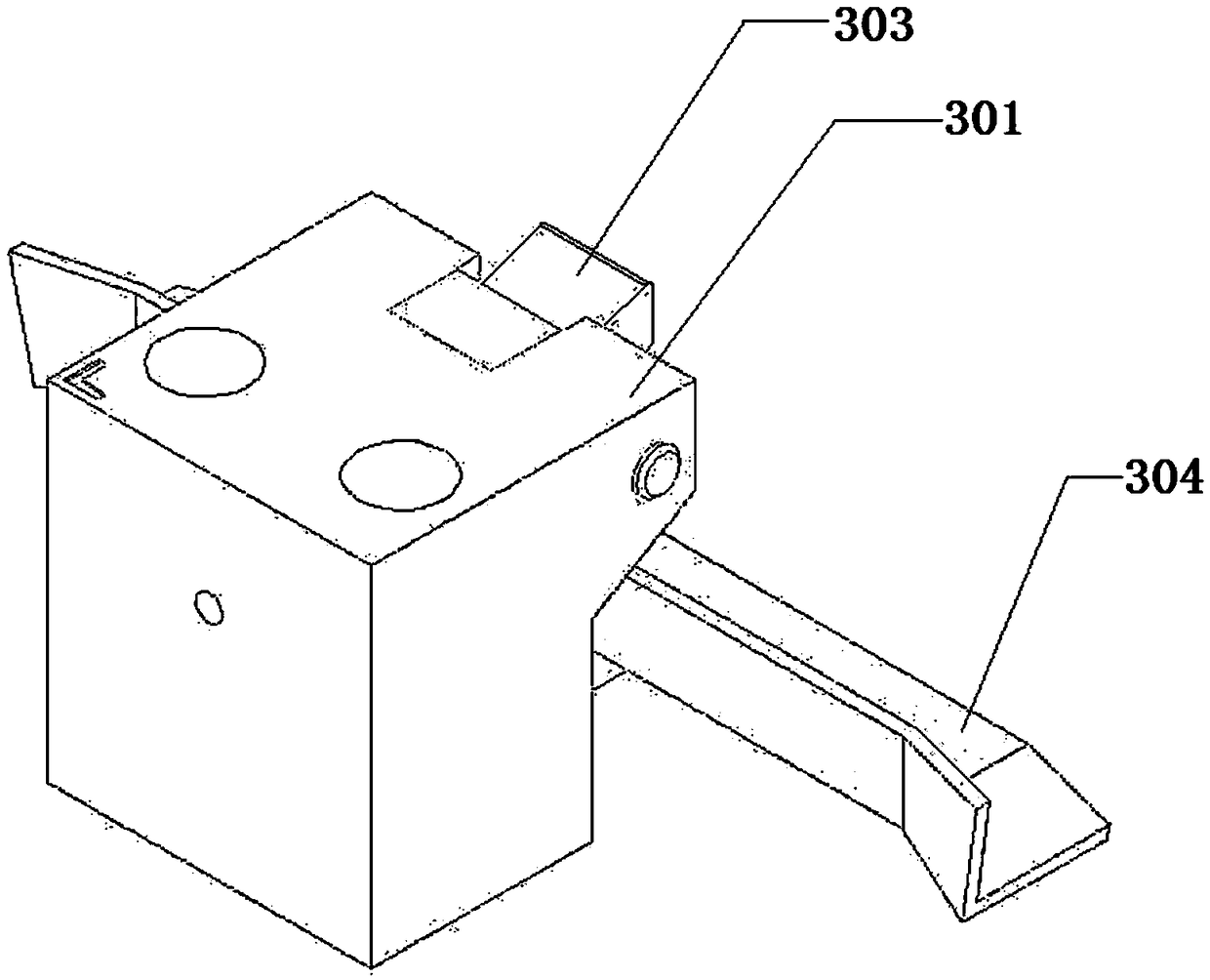

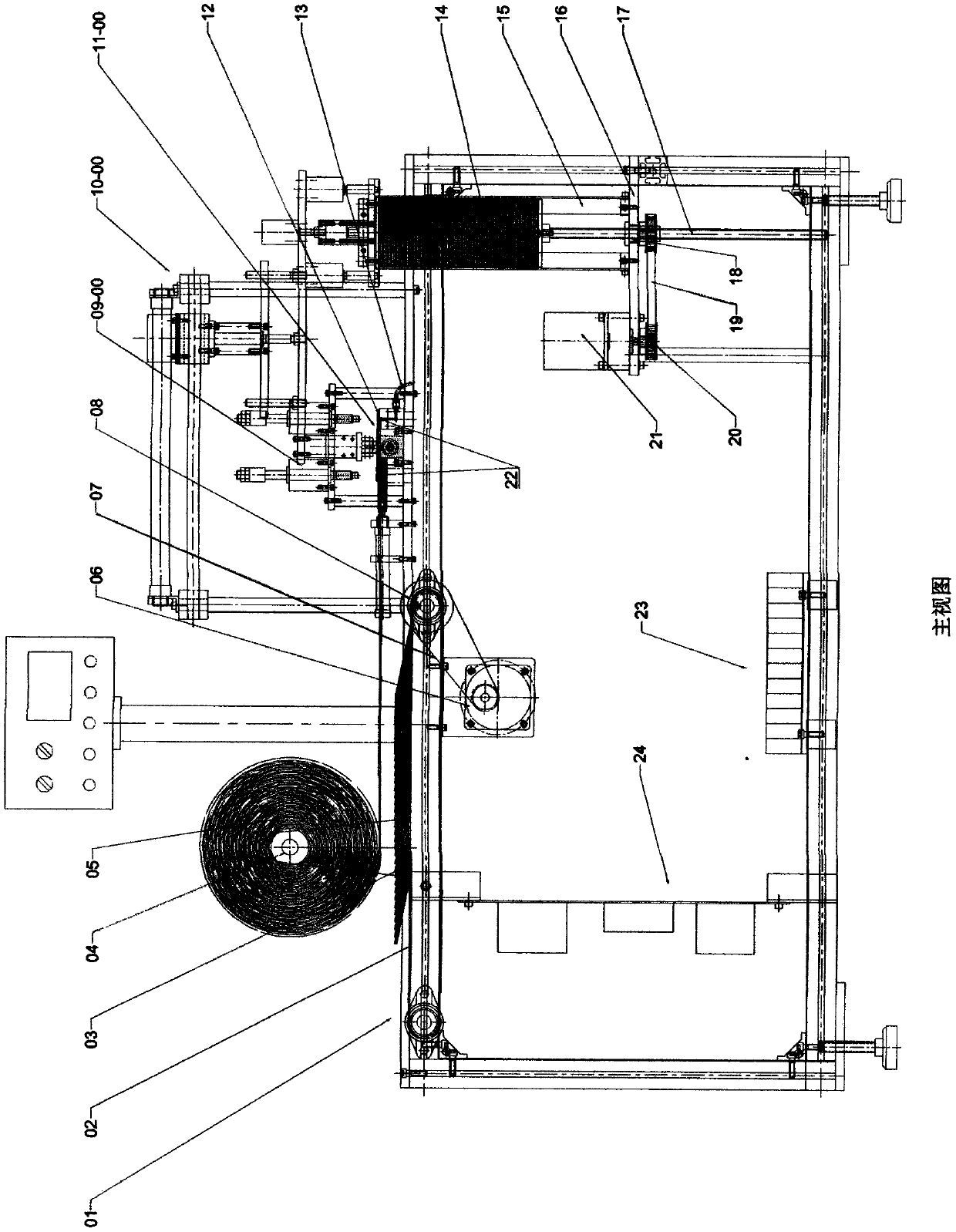

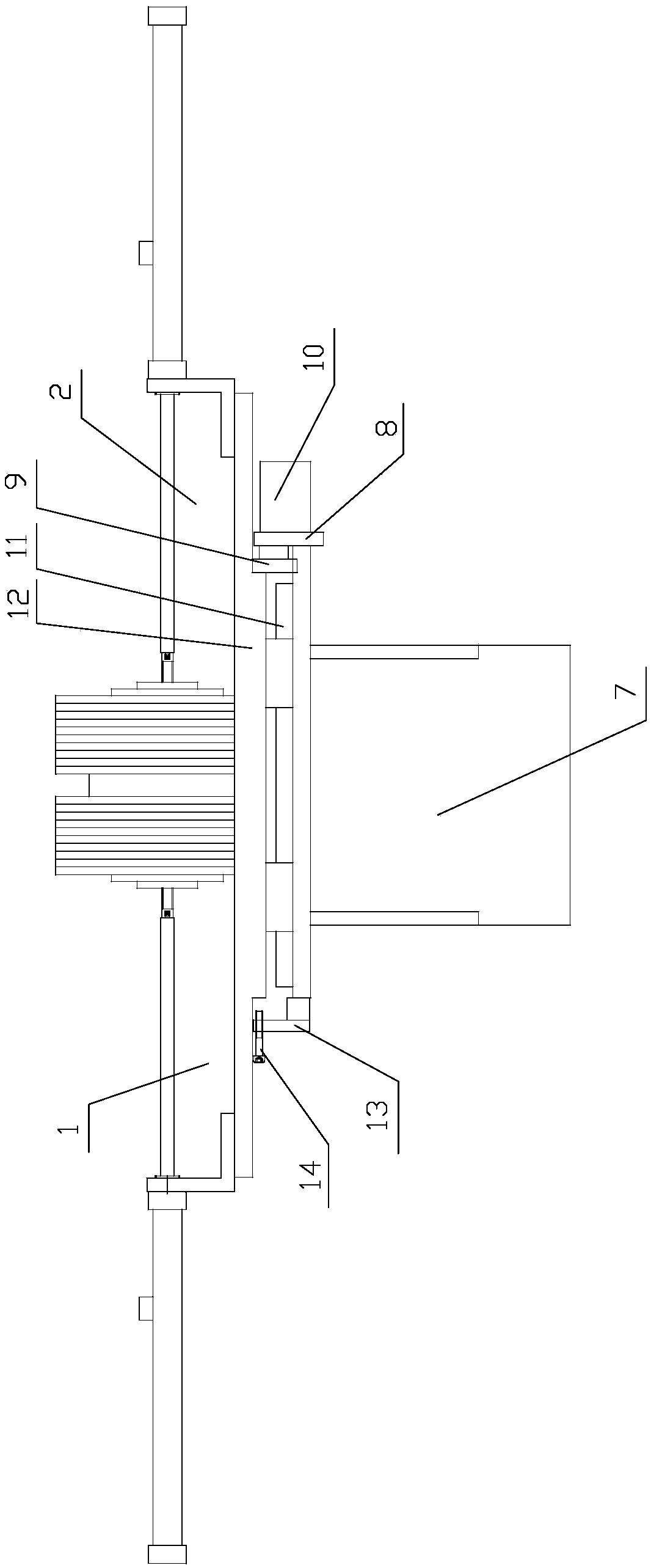

Automatic coiling device for steel strip coil with inner ring provided with folding head and use method thereof

InactiveCN105772534AHigh degree of automationImprove productivityMetal working apparatusLaser rangingLaser rangefinder

The invention relates to the field of tight coiling or coiling or uncoiling of metal strip materials, in particular to an automatic coiling device for a steel strip coil with the inner ring provided with a folding head and a use method thereof. The automatic coiling device for the steel strip coil with the inner ring provided with the folding head comprises an uncoiling machine (1), and is characterized by further comprising a gear motor (2), a laser range finder (3), laser probes (4) and sleeves (5), wherein a groove is formed in the lateral wall of one end surface of each sleeve (5); the sleeves (5) are arranged outside a coiling drum (12) in a sleeving mode; a stepping motor (11), the gear motor (2), the laser range finder (3) and the laser probes (4) are connected with a controller (6) through signal lines. The use method of the automatic coiling device for the steel strip coil with the inner circle provided with the folding head is characterized by including the following steps of a, axis alignment; b, measurement of the folding head; c, alignment of the folding head; and d, uncoiling. The automatic coiling device for the steel strip coil with the inner ring provided with the folding head and the use method thereof are high in automation degree, high in production efficiency and wide in application range.

Owner:BAOSTEEL ENG & TECH GRP

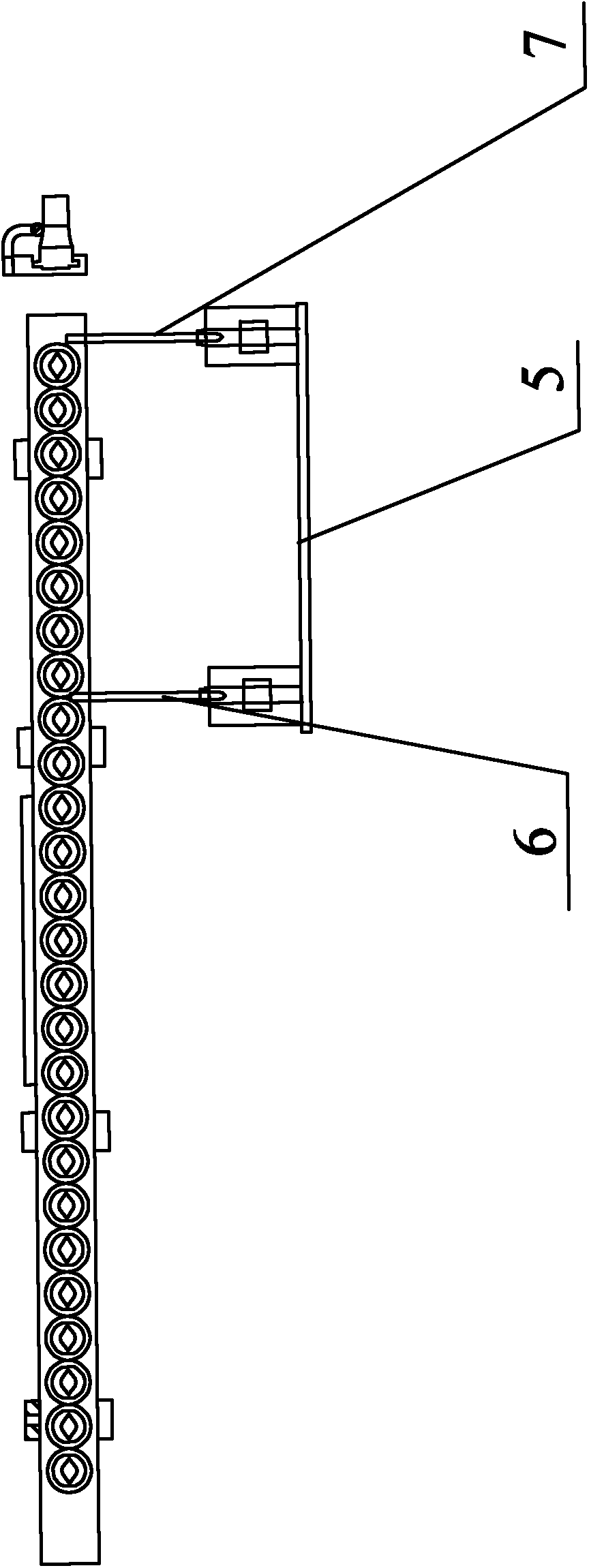

Single crystal silicon loading system

InactiveCN103922115ASolve the problem of automatic feedingIncrease productivityCharge manipulationConveyor partsEngineeringPosition sensor

The invention discloses a single crystal silicon loading system. The single crystal silicon loading system comprises a support, a transport portion installed on the support, a correction portion which is installed on the support and stretches across the transport portion, a power system which provides power for the transport portion, and a position sensor installed at one end of the support and used to sense whether the transport portion is provided with single crystal silicon or not. Compared with the prior art, the single crystal silicon loading system achieves the result that the single crystal silicon can be automatically loaded when silicon slices are automatically produced on a large scale, and therefore the single crystal silicon loading system facilitates production efficiency improvement of the silicon slices and production cost reduction of the silicon slices.

Owner:SIP GOLDWAY TECH

Powder cake emulsification foaming agent

InactiveCN107041401AImprove liquiditySolve the problem of automatic feedingDough treatmentDough/pre-mixesAdditive ingredientGlycerol

The invention discloses a powder cake emulsification foaming agent comprising the following substance ingredients by weight percentage: polyglycerol fatty acid ester 20-45%, carrier 55-80%, and pourified water 1-2%; the polyglycerol fatty acid ester esterification oil refers to one or more types of the following oil: 2, 3, 4, 6 10 polyglycerol; the polyglycerol fatty acid ester esterification acid refers to one or more types of the following acids: stearic acid, oleic acid, linoleic acid, palmitic acid, myristic acid, and lauric acid; the carrier refers to maltodextrin or glucose syrup. The powder cake emulsification foaming agent is in a powder state, good in fluidity, simple in product ingredients, easy to operate in production technology, can effectively ensure the product quality and usage effect continuity, and is suitable for large scale production of cake products.

Owner:嘉益食品科技(昆山)有限公司

Plastic particle extruder capable of automatic feeding

InactiveCN109382994ASolve the problem of automatic feedingRealize automatic feeding processSlide plateEngineering

The invention discloses a plastic granule extruder capable of automatic feeding. The plastic granule extruder comprises a bottom plate, wherein an extruder is fixedly connected to the left side of thetop of the bottom plate; a feeding hopper communicates with the right side of the top of the extruder; a sliding plate is glidingly connected to the top of the bottom plate and located on the right side of the extruder; a first threaded rod and a second threaded rod are respectively and rotationally connected to the front side and the rear side of the top of the bottom plate; and the surfaces ofthe first threaded rod and the second threaded rod are respectively in threaded connection with threaded blocks. The invention relates to the technical field of extruders. According to the plastic particle extruder capable of automatic feeding, by cooperation of the structures, the first threaded rod and the second threaded rod are utilized to drive the two threaded blocks to move up and down, a sliding seat is simultaneously driven to move from side to side through an air cylinder, and an arc-shaped feeding plate is indirectly driven to rotate at a certain angle, thereby avoiding manual feeding, and realizing the process of automatic feeding; and the plastic granule extruder is convenient in operation process and high in work efficiency, and saves the labor cost.

Owner:YANCHENG QINGDA NEW MATERIAL CO LTD

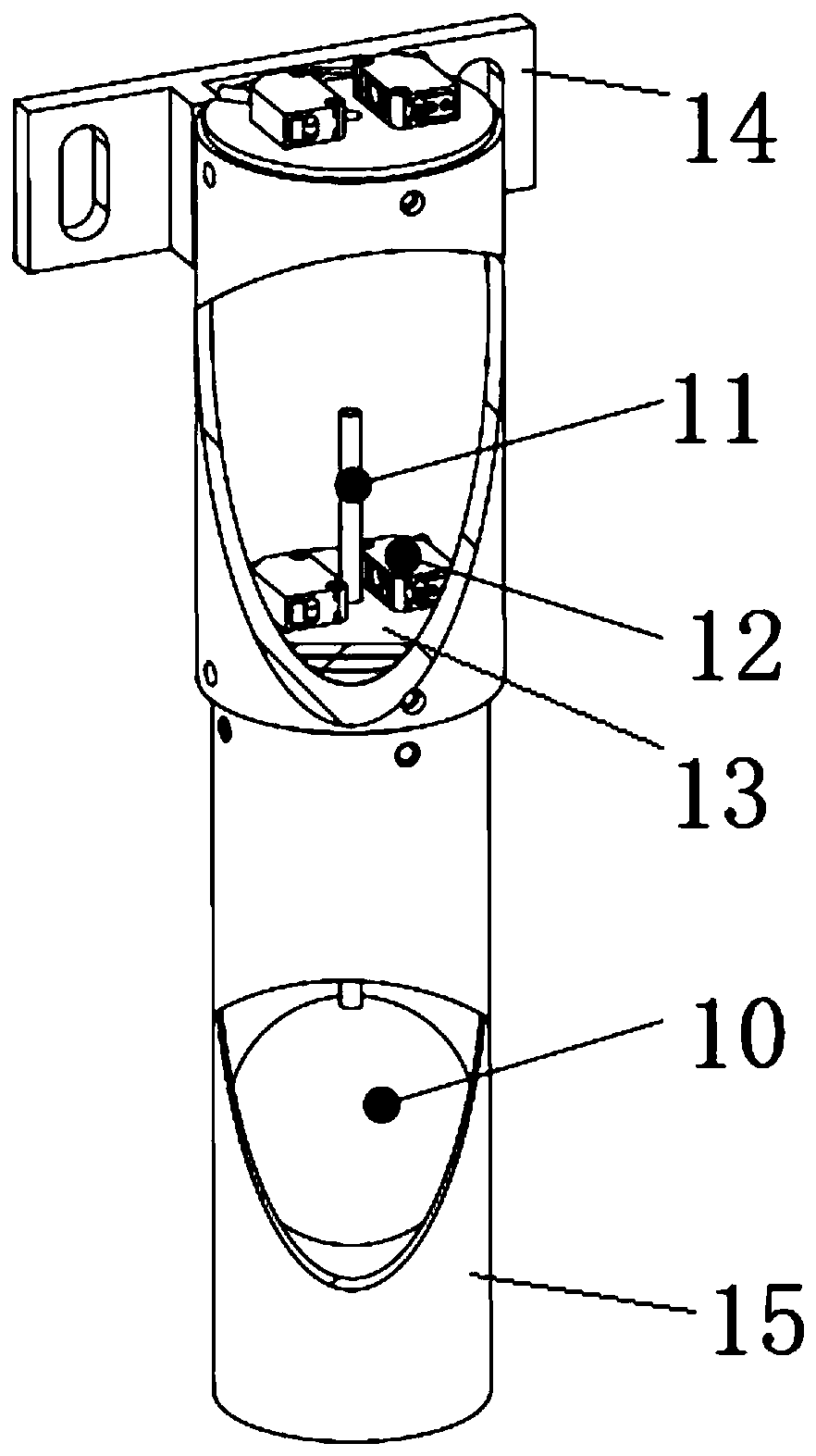

Automatic feeding device for knitter and control method

ActiveCN106757759ARealize automated productionSolve the problem of automatic feedingBraidFall detectionEngineering

The invention discloses an automatic feeding device for a knitter. The automatic feeding device comprises the knitter, a tractor and an automatic feeding device body, wherein the automatic feeding device body comprises a base, a charging conduit, an adjustment bracket, a falling steel core detection sensor, an incomplete filling detection sensor, a belt pulley, a support, a falling motor, a rubberized steel core, a first annular steel core measurement sensor, a steel core falling detection sensor, a cylinder front position magnetic switch, a buffer cylinder, a knitting point magnetic switch, a feeding cylinder, a cylinder rear position magnetic switch, a slider and a guide rail. Automatic feeding of the steel core in the knitting process can be realized; when the phenomena that the steel core does not fall, two steel cores fall together, the steel core is not on a feeding rack, and the knitter is in an empty knitting state are discovered, the knitter is stopped immediately, an alarm is given and automatic production is realized.

Owner:NANJING ORIENTLEADER TECH CO LTD

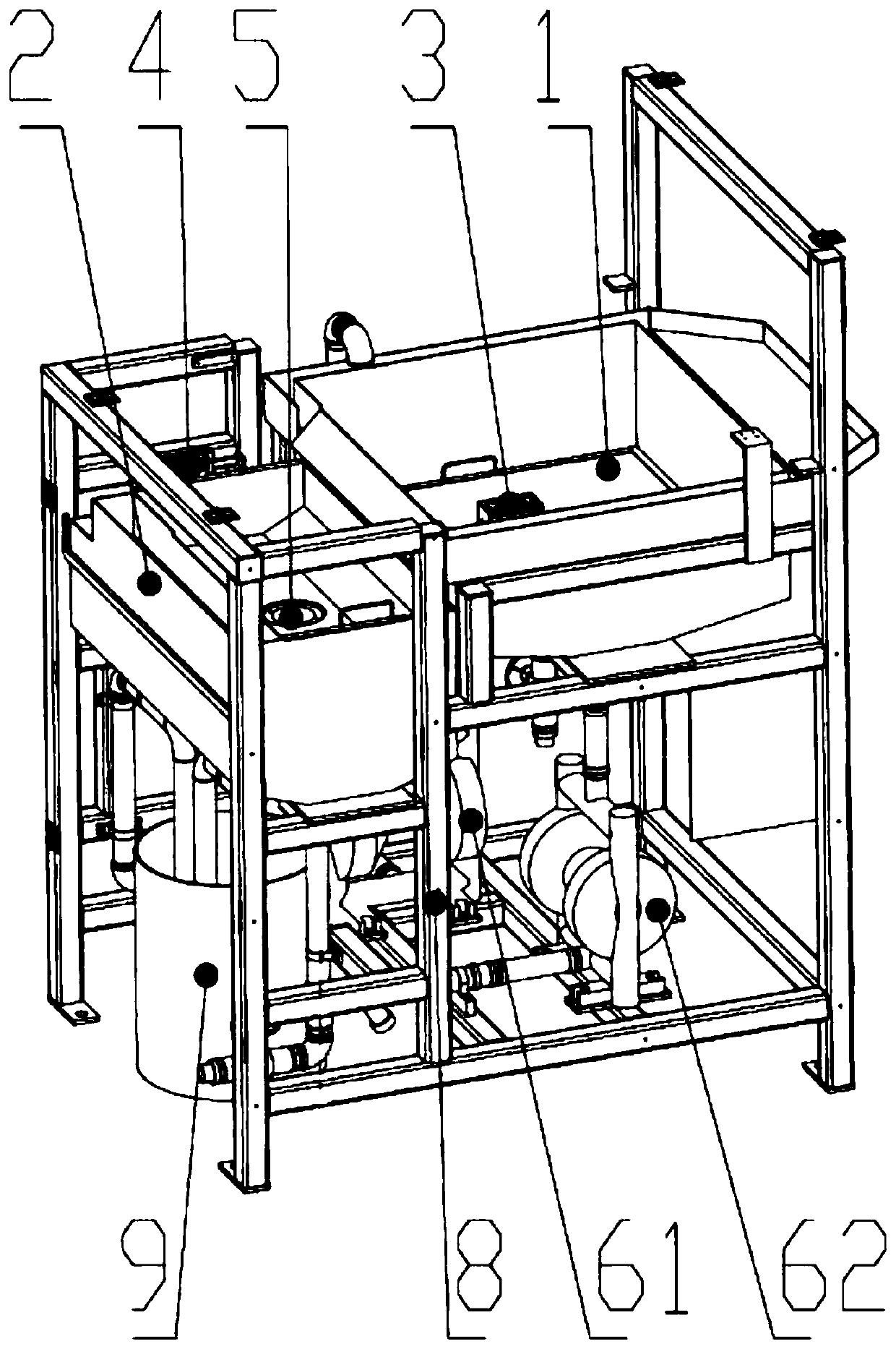

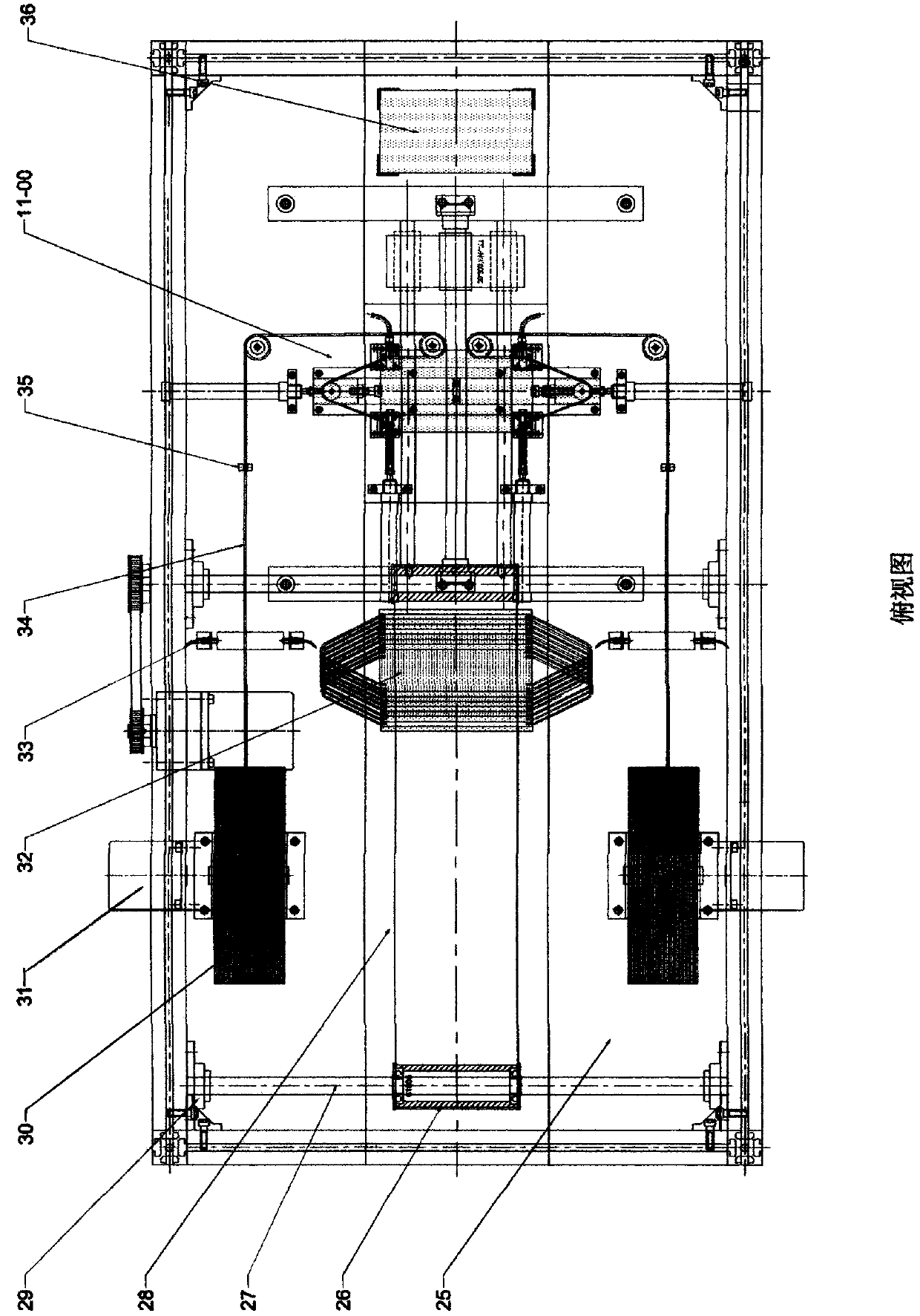

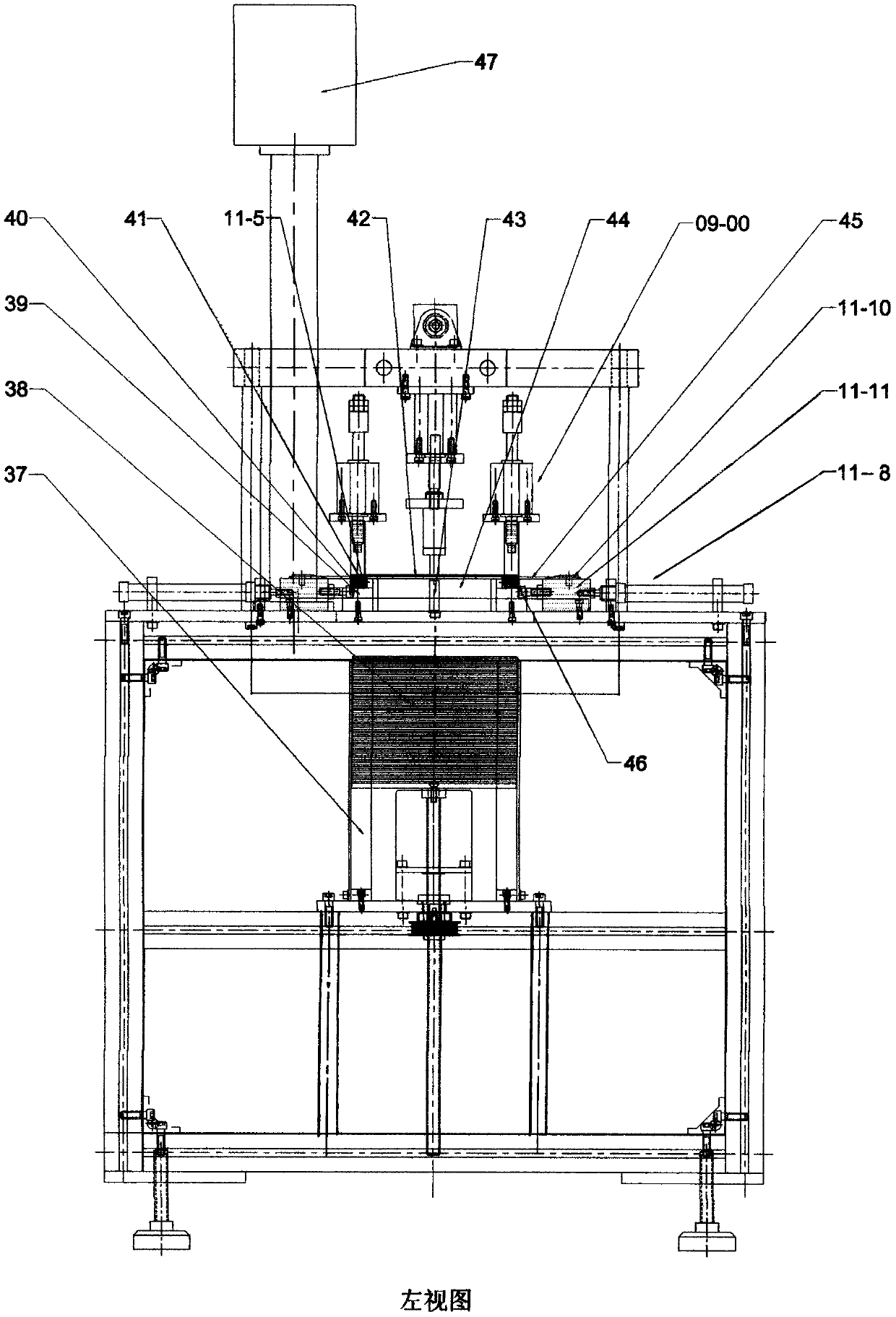

Full-automatic paint pool device for sand core dip-coating

InactiveCN111558699ARealize fixed-point dip coatingAltitude constantMoulding toolsProcess engineeringMechanical engineering

The invention discloses a full-automatic paint pool device for sand core dip-coating. The full-automatic paint pool device for sand core dip-coating comprises an automatic paint feeding pipeline system, a paint circulating flow pipeline system, a dip-coating pool with a constant liquid level, a paint filtering pool, two sets of liquid level height detection devices, a supporting frame, and a paintbucket. The dip-coating pool and the paint filtering pool are fixed to the supporting frame, the liquid level height detection devices are arranged in the dip-coating pool and the paint filtering pool, the automatic paint feeding pipeline system is connected with the paint bucket and the dip-coating pool and used for supplying paint in the paint bucket to the dip-coating pool, the paint circulating flow pipeline system is connected with the paint filtering pool and the dip-coating pool and used for supplying the paint in the paint filtering pool to the dip-coating pool, and when a second upper liquid level setting value is reached, the paint circulating flow pipeline system stops. The automatic supply of the paint is achieved, and the liquid level height of the paint pool is kept constant.

Owner:JARI AUTOMATION CO LTD CHINA

Long-strip-shaped polymer material feeding method and device

PendingCN109910098ASolve the problem of automatic feedingIncrease profitMetal working apparatusEconomic benefitsEngineering

The invention discloses a long-strip-shaped polymer material feeding method and device. The long-strip-shaped polymer material feeding method comprises the steps that a feeding channel is arranged ina feeding device, raw materials are put into the feeding channel, and a gas driving device is used for blowing gas to the feeding channel to enable the raw materials to move in the feeding channel; and a positioning knife is arranged on the outer side of the feeding channel, when the gas driving device blows the gas to the feeding channel, the positioning knife can block the front of the raw materials in advance, so that the positioning knife can block the movement of the raw materials, and thus the distance of the movement of the raw materials is positioned. According to the long-strip-shapedpolymer material feeding method and device, feeding is carried out through an air-operated mode, the automatic feeding of thin-soft type and thin-long type polymer materials is effectively realized,and the automated production for processing super-small type polymer material products with ultrathin wall thicknesses and high precision is realized; meanwhile, the material use ratio is improved, the labor intensity of operators is reduced, and good economic benefits are obtained; the structure is simple, the manufacturing and maintenance costs are low, no site is occupied, and a feeding power medium is the gas; and compared with a traditional feeding device, the long-strip-shaped polymer material feeding device is safer and cleaner, and the operation is easier.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

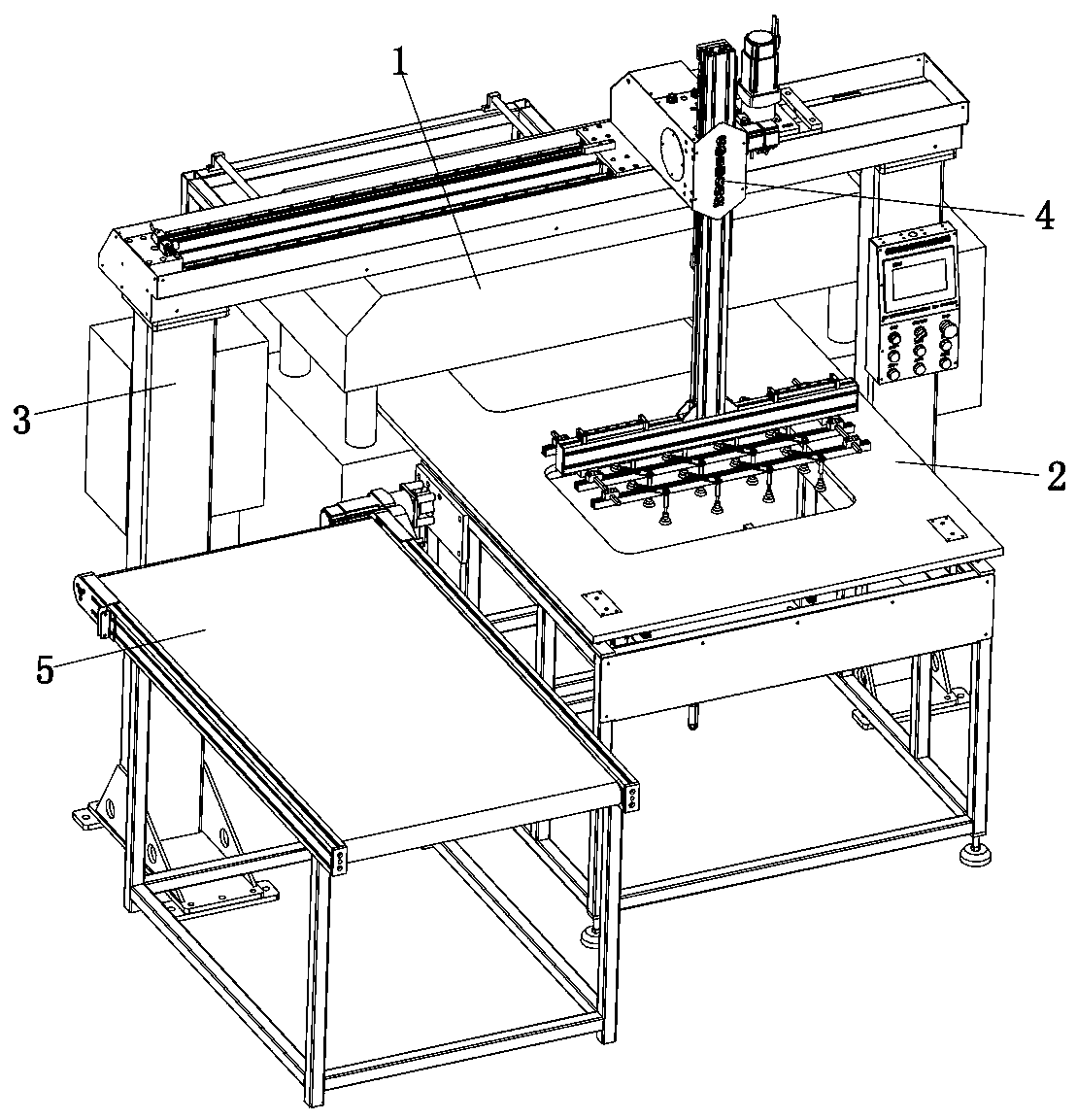

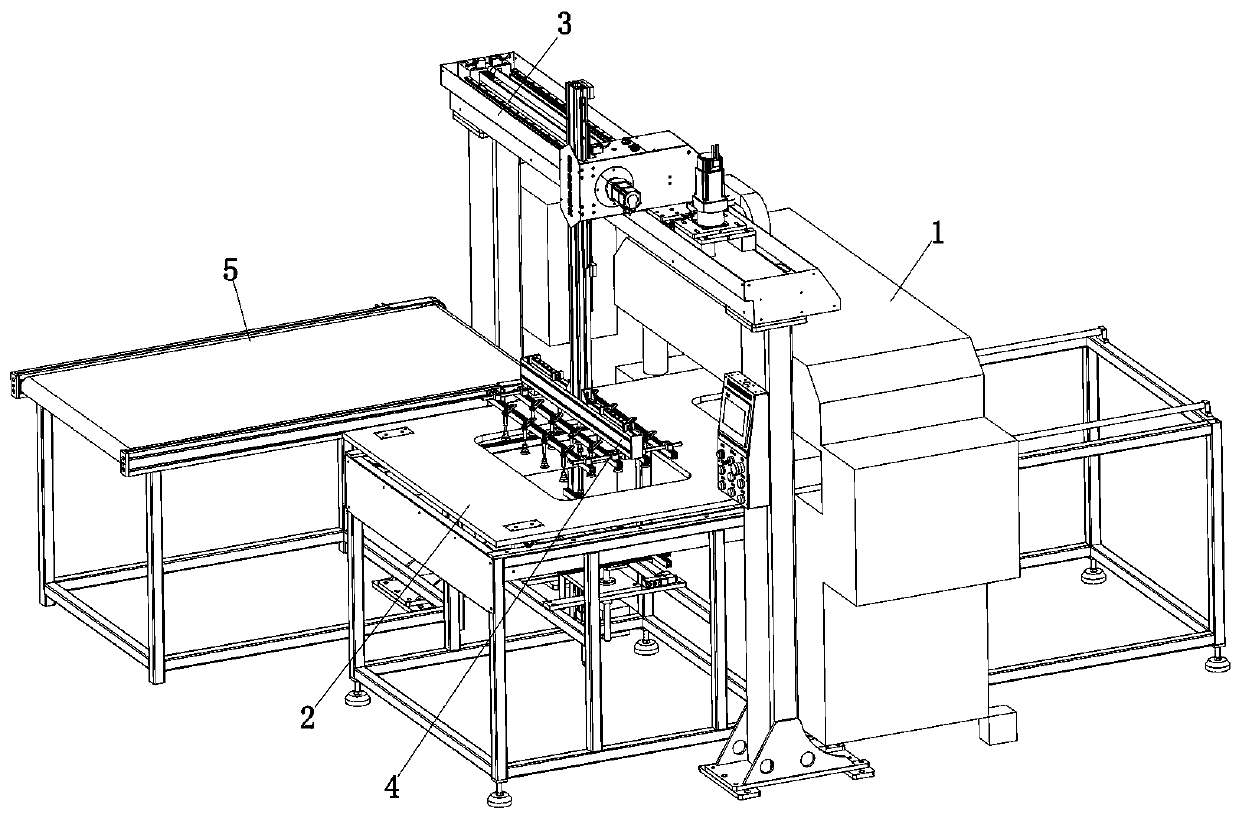

Automatic feeding and discharging device for assisting in plastic uptake

PendingCN109896269AReduce blister costImprove blister production efficiencyConveyor partsSingle platePlastic film

The invention discloses an automatic feeding and discharging device for assisting in plastic uptake. The automatic feeding and discharging device comprises a plastic uptake mechanism, a pushing mechanism, a taking and placing mechanism and a discharging mechanism; the pushing mechanism is horizontally arranged; a carrying plate at the top of the pushing mechanism linearly slide to and fro in the straight line direction; the plastic uptake mechanism comprises an upper plastic uptake part and a lower plastic uptake part; the two plastic uptake parts are separately and correspondingly arranged atthe upper part and the lower part of the pushing mechanism up and down; the taking and placing mechanism spans a part above the pushing mechanism; the discharging mechanism is arranged on one side ofthe pushing mechanism; and a plastic sheet to be plastic-uptaken is loaded on the carrying plate of the pushing mechanism. In plastic uptake, a plastic hard plate is automatically sucked in, and a product is automatically ejected or pushed back and automatically sucked and carried after plastic uptake is finished, so that the production efficiency of the plastic uptake is effectively improved, the plastic uptake cost of a single plate is reduced, and the plastic uptake quality is ensured well.

Owner:深圳市优赫自动化科技有限公司

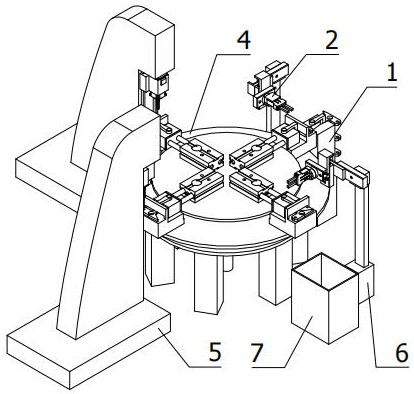

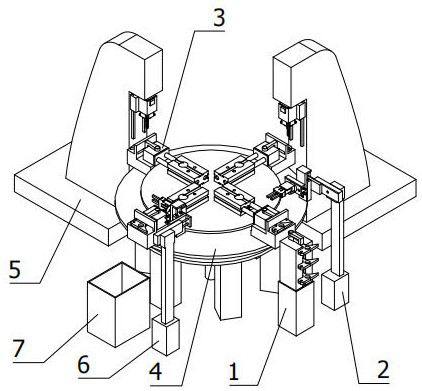

Automatic machining equipment for automobile rocker arm

InactiveCN113020656ASolve the technical problems of automatic processingSolve the problem of automatic feedingMetal working apparatusPositioning apparatusSlide plateControl theory

The invention relates to the field of automatic machining, in particular to automatic machining equipment for an automobile rocker arm. The equipment comprises a feeding device, a feeding robot, a fixing device, a rotating device, a machining device, a discharging robot and a discharging basket. The feeding device comprises a fixing frame, a first single-shaft air cylinder and a first sliding block. The feeding robot comprises a supporting column, a transverse driver, a transverse sliding plate, a longitudinal driver, a longitudinal sliding plate, a swing air cylinder, a fixing frame and a finger air cylinder. The fixing device comprises a stand column, a fixing disc, a double-shaft double-rod air cylinder, a pressing block and a fixing block. A to-be-machined automobile rocker arm is upwards conveyed to the input end of the feeding robot through the feeding device, then the to-be-machined automobile rocker arm is placed on the fixing device to be fixed through clamping of the feeding robot, then the rotating device rotates to rotate the automobile rocker arm to the output end of the machining device, the automobile rocker arm is machined through the machining device, finally, discharging is conducted, and the technical problem of how to automatically machine the automobile rocker arm is solved.

Owner:汪闰

Material conveying and discharging device of metal plates

InactiveCN108080508ASolve the problem of automatic feedingSimple structureShaping toolsMetal-working feeding devicesEngineeringWaste material

The invention discloses a material conveying and discharging device of metal plates. The material conveying and discharging device comprises an upper mould, a lower mould a fixed base, a material ejection device, a rotary material supporting block and an automatic material conveying device; the fixed base is arranged on the lower mould; a groove is formed in the fixed base and faces to the inner side of a mould; a rotary block is rotatably arranged on the groove; the material injection device is arranged on the upper mould and clings to the top of the rotary material supporting block; a resetspring mechanism which is used for ejecting the rotary materials supporting block is arranged between the rotary material supporting block and the groove; the automatic material conveying device is arranged in the fixed base; the automatic material conveying device comprises a pressing rod and an intermittent feeding wheel; the pressing rod is vertically arranged on the upper surface of the fixedbase; and the intermittent feeding wheel is arranged on the side surface of the fixed base. By adopting the material conveying and discharging device, the problem in the prior art that a traditional fixed positioner inhibits sliding out of waste materials is solved; the defect of incapability of automatic material conveying is overcome; and the material conveying and discharging device has the characteristics of being simple in structure and high in production efficiency.

Owner:芜湖瑞鹄浩博模具有限公司

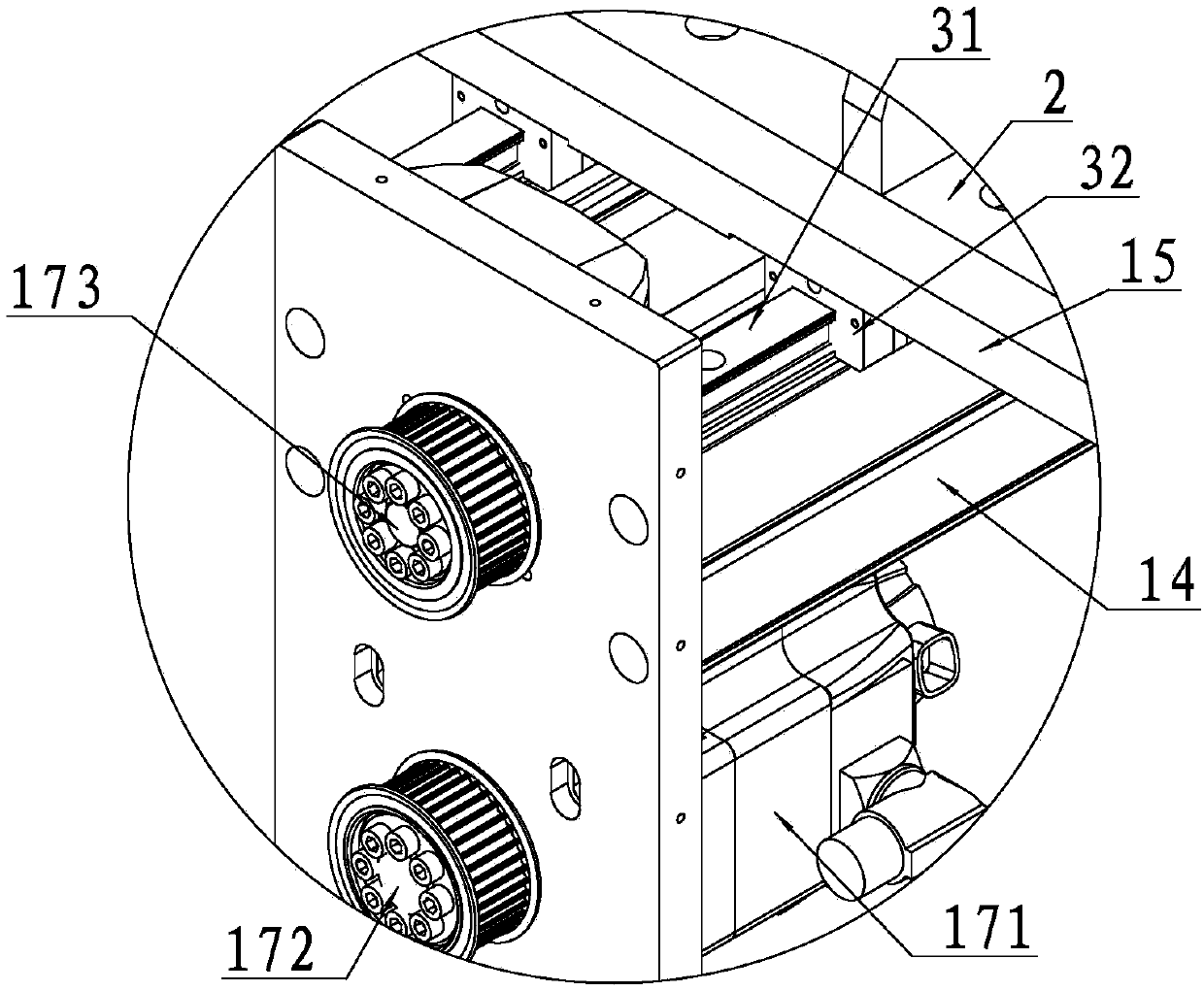

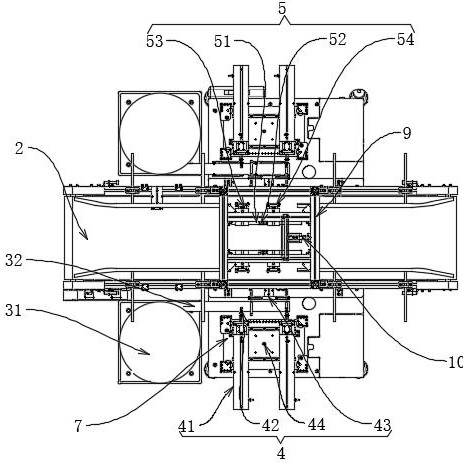

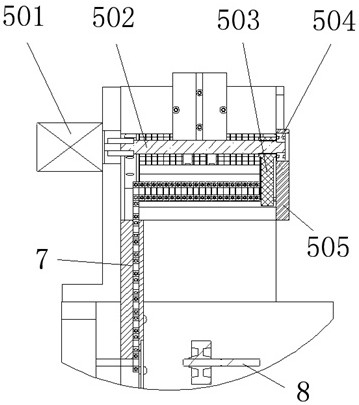

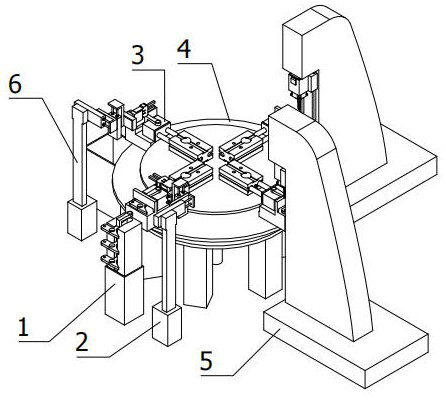

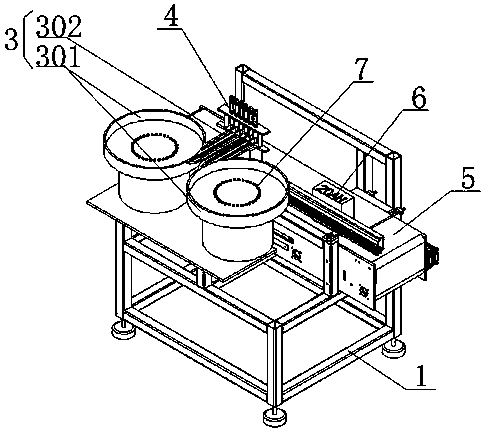

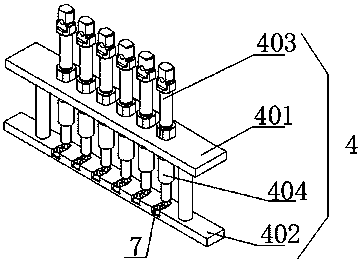

Full-automatic mask ear belt welding machine

InactiveCN111347680ASolve the problem of automatic feedingHigh speedDomestic articlesHand partsRobot hand

The invention discloses a full-automatic mask ear belt welding machine which is composed of 1, a mask lifting and supplying part, 2, a mask feeding mechanical hand part, 3, an ear belt feeding part, 4, ear belt welding parts, 5, an automatic collecting part, 6, a machine platform, 7, a pneumatic system, and 8, a PLC electrical control part. The full-automatic mask ear belt welding machine is characterized in that the right side of the lower portion of the machine platform is provided with the mask lifting and supplying part, the right side of the upper portion of the machine platform is provided with a mask feeding mechanical hand, the left side and the right side of the mechanical hand are provided with the ear belt welding parts, and the lower portions of the ear belt welding parts are provided with the ear belt feeding part; the left side of the upper portion of the machine is provided with an ear belt material and the automatic collecting part, and the lower portion of the machineis provided with a machine platform part; and the left side of the interior of the machine platform is provided with a pneumatic system and the electrical part. According to the full-automatic mask ear belt welding machine, the problems of independent automatic ear belt welding and automatic feeding are well solved, thus, ear belt welding of a mask machine can be subjected to separated machining,several stations can be made to work at the same according to the speed of the mask machine, and thus, the speed is greatly increased.

Owner:深圳市中发技术有限公司

Automatic feeding device of particle crumble blank

InactiveCN102514093ASolve intermittent operation and yield can not be improvedSolve the problem of automatic feedingAuxillary shaping apparatusLower yieldEngineering

The invention relates to an automatic feeding device of a particle crumble blank, which comprises a table, a feed control device and a slippery feed plate. The table is provided with a mold hole and the slippery feed plate slides through a feed position, the feed control device and the mold hole. The slippery feed plate comprises a measuring tank plate and a sliding plate. The measuring tank plate is provided with a plurality of measuring tanks in parallel that receive particle crumble blank. The sliding plate is arranged below the measuring tanks and can shield and expose the measuring tanks slidably. When the measuring tanks are in the feed position, the measuring tanks are filled with particle crumble blank. The measuring tank plate is provided with a fixing device for limiting the sliding plate to move together or separately. By application of multi-mean quantification such as sieving, distributing, scraping, weighing and the like in the whole transport process, the problem in automatic feeding caused by easy adhesion of wet crumble powder blank which cannot be combed and the problems of interrupted operation and low yield caused by unstable automatic feeding in the blank forming process can be solved.

Owner:李建华

Electromagnetic bidirectional switching scraper device applied to 3D printer

PendingCN111873126ASolve the problem of automatic feedingGuaranteed accuracyAdditive manufacturing apparatusCeramic shaping apparatusComputer printingControl theory

The invention provides an electromagnetic bidirectional switching scraper device applied to a 3D printer. The electromagnetic bidirectional switching scraper device comprises a horizontal moving sliding plate, a scraper frame and a height limiting base; scrapers and limiting guide rods are arranged on the two sides of the scraper frame; and the scraper frame is connected with the horizontal movingsliding plate through a rotating shaft, when the scraper frame reaches the position of the height limiting base, the limiting guide rods make contact with an inclined wedge face on the top of the height limiting base and move downwards, the scraper frame swings on the horizontal moving sliding plate, and therefore the scrapers on the two sides of the scraper frame are switched. Automatic switching of the double scrapers is achieved during left-right movement, the automatic feeding problem of the 3D printer is solved, an electromagnet device and the height limiting base are used in cooperation, the scraper precision is guaranteed, meanwhile, the scraper replacing process is faster, the scraper replacing manner is stable and reliable, and the 3D printer can achieve unmanned and automatic operation, machining and feeding through the scraper device, so that the problem that the manual smearing precision is not stable is solved, and the problems about working precision, efficiency and reliability are solved.

Owner:江苏乾度智造高科技有限公司

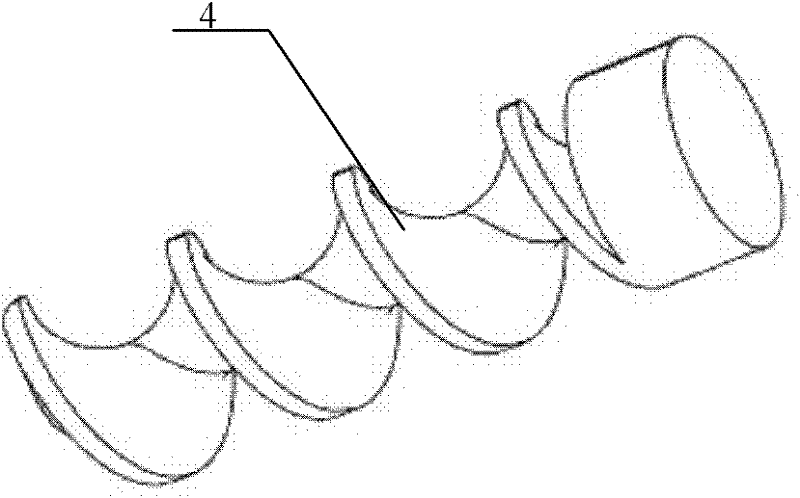

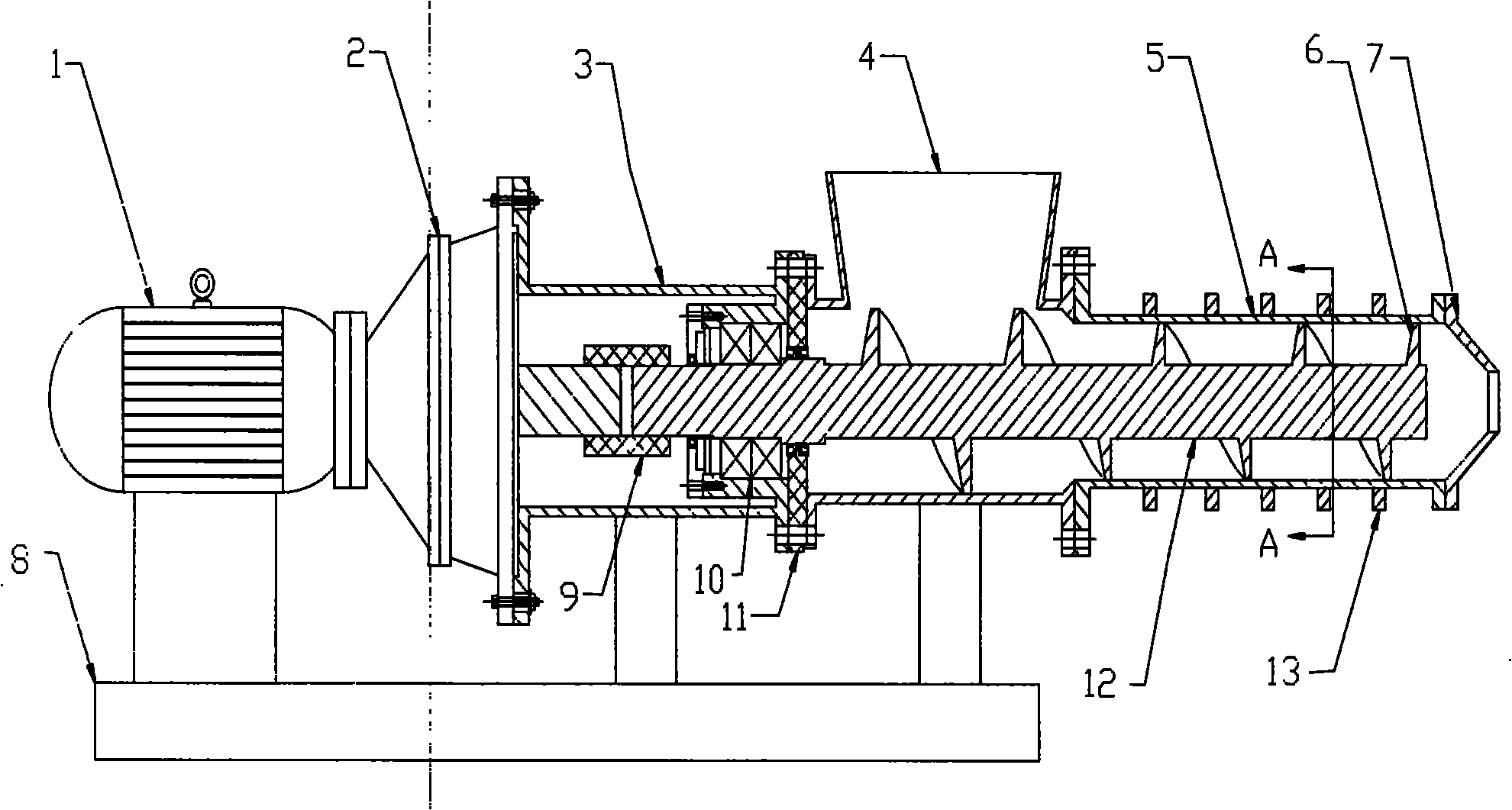

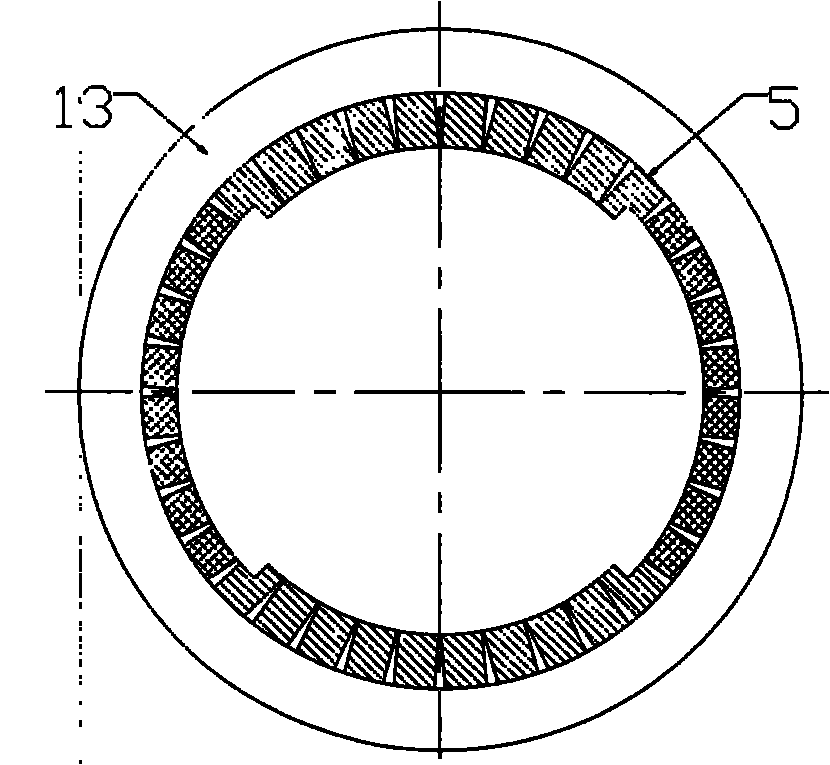

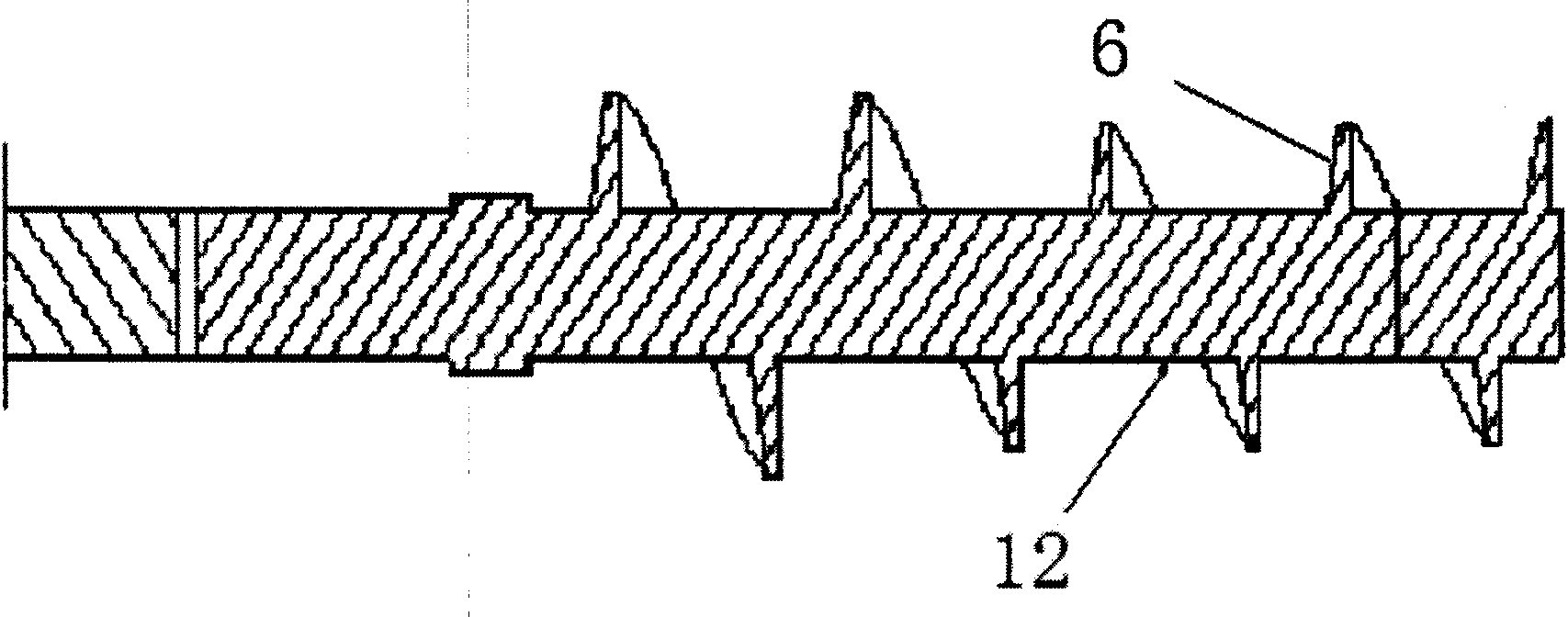

Helical main shaft and water-entrained feather wringing dehydrator

ActiveCN101963441AReasonable structural designImprove drying effectDrying solid materialsDrying machinesHelical bladeMoisture

The invention relates to a helical main shaft and a water-entrained feather wringing dehydrator, and belongs to the technical field of processing equipment of feather albumen powder. The helical main shaft is characterized in that: screw blades of which the screw pitches are decreased progressively are arranged on a peripheral shaft wall; and the screw blades have two external-diameter dimensions and are arranged on the shaft wall from large to small. The water-entrained feather wringing dehydrator is characterized in that: a squeezing cavity formed by arranging squeezing strips with different sectional dimensions at intervals is formed at the periphery of the helical main shaft; a conical die head for blocking materials is arranged at the port of the squeezing cavity; helical blades of which the screw pitches are decreased progressively are arranged on the shaft wall of the helical main shaft; and the external-diameter dimensions of helical blades positioned in a feeding box are greater than those of the helical blades positioned in the squeezing cavity. In the helical main shaft and the water-entrained feather wringing dehydrator, the moisture content of feather can be greatly reduced, the production cost is reduced, and the production efficiency is high; and the helical main shaft and the water-entrained feather wringing dehydrator can be operated continuously and are difficult to block, slip and the like.

Owner:山东丰获机械制造有限公司

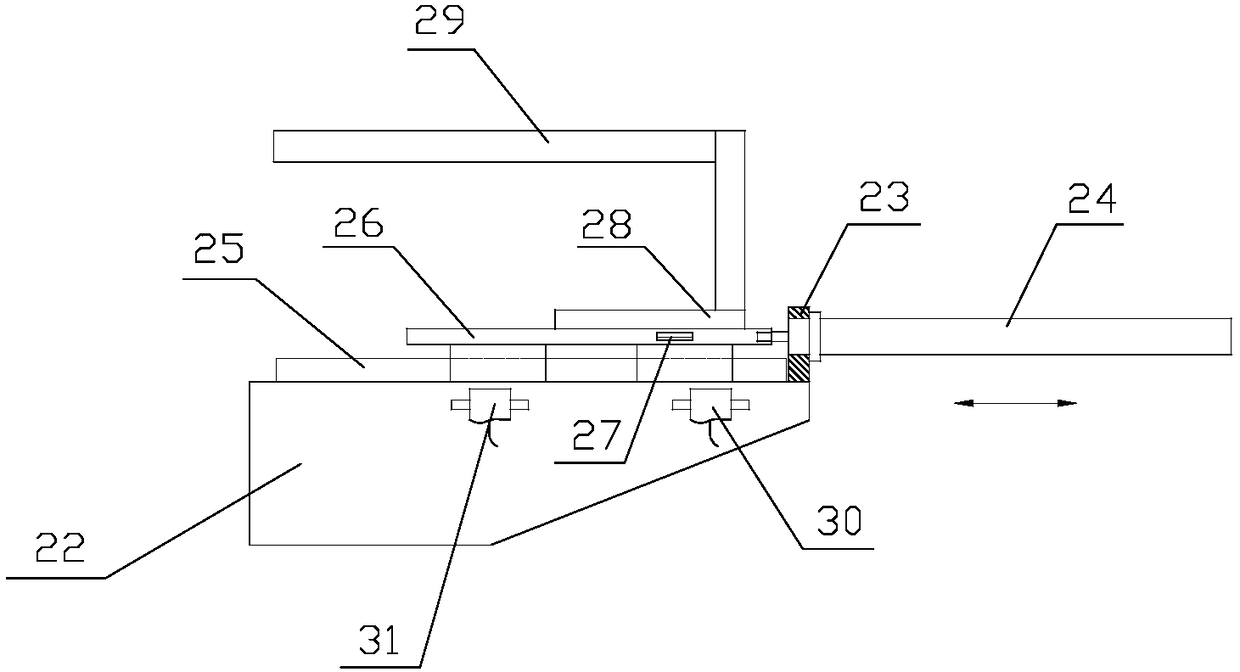

Special continuous feeding device for mobile phone aluminum plate grinding for double ended grinding machine

PendingCN108481106ASolve the problem of automatic feedingImprove processing efficiencyGrinding feedersPlane surface grinding machinesEngineeringMobile phone

The invention provides a special continuous feeding device for mobile phone aluminum plate grinding for a double ended grinding machine. The special continuous feeding device solves the technical problems of high labor cost, low production efficiency and low product qualification rate of mobile phone aluminum plate grinding feeding of an existing double ended grinding machine. The special continuous feeding device comprises bases, and the bases are provided with a lateral reversing mechanism capable of sliding left and right in a reciprocating mode and a longitudinal feed mechanism capable ofsliding back and forth in a reciprocating mode. The moving direction of the lateral reversing mechanism is perpendicular to the moving direction of the longitudinal feed mechanism, the lateral reversing mechanism is provided with a separation plate, and an A feeding chute and a B feeding chute are separately and symmetrically formed in the left and right sides of the separation plate. The specialcontinuous feeding device for mobile phone aluminum plate grinding for the double ended grinding machine can be used for continuous feeding of aluminum plates of the double ended grinding machine.

Owner:RUSHAN HONGYUAN MACHINE MFG

Automatic cover safety valve equipment and safety valve for battery production

PendingCN109148788ASave human effortIncrease productivityFinal product manufactureCell component detailsEngineeringSafety valve

The invention relates to the technical field of lead-acid battery, which discloses an automatic cover safety valve device and a safety valve used for battery production. The battery conveying device is located below the safety valve pressing cover device and is used for conveying the battery to be pressed on the safety valve pressing cover device directly below the safety valve pressing cover device. The discharge port of the relief valve feeding device is engaged with one side of the relief valve pressing cover device for feeding the relief valve positioned thereon to the lower part of the relief valve pressing cover device and to the upper part of the battery to be pressed cover. The device realizes the valve-regulated lead-acid battery full-automatic cover safety valve, replaces the original manual cover safety valve process, reduces the labor cost, increases the production efficiency by 400%, and helps to improve the product quality stability; The structure of the safety valve solves the sticking phenomenon of the surface of the safety valve and the vibration disk and the sticking phenomenon of the bottom edge and the closed top surface between the adjacent safety valves, thereby ensuring that the vibration disk can continuously feed the safety valve automatically, and further realizing the automatic cover valve through the automatic equipment.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com