Environment-friendly garbage recycling and treating device

A recycling and environmental-friendly technology, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of long time, high production cost, expensive price, etc., to improve compression efficiency, prolong service life, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

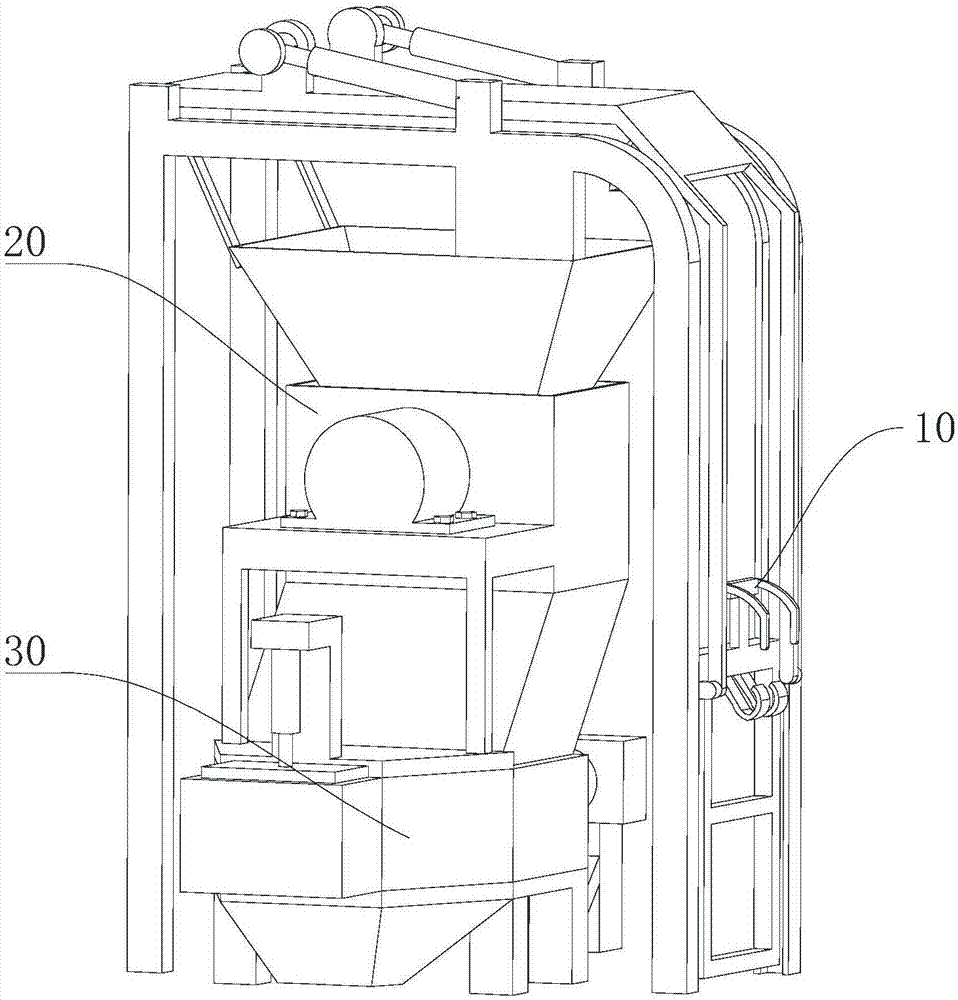

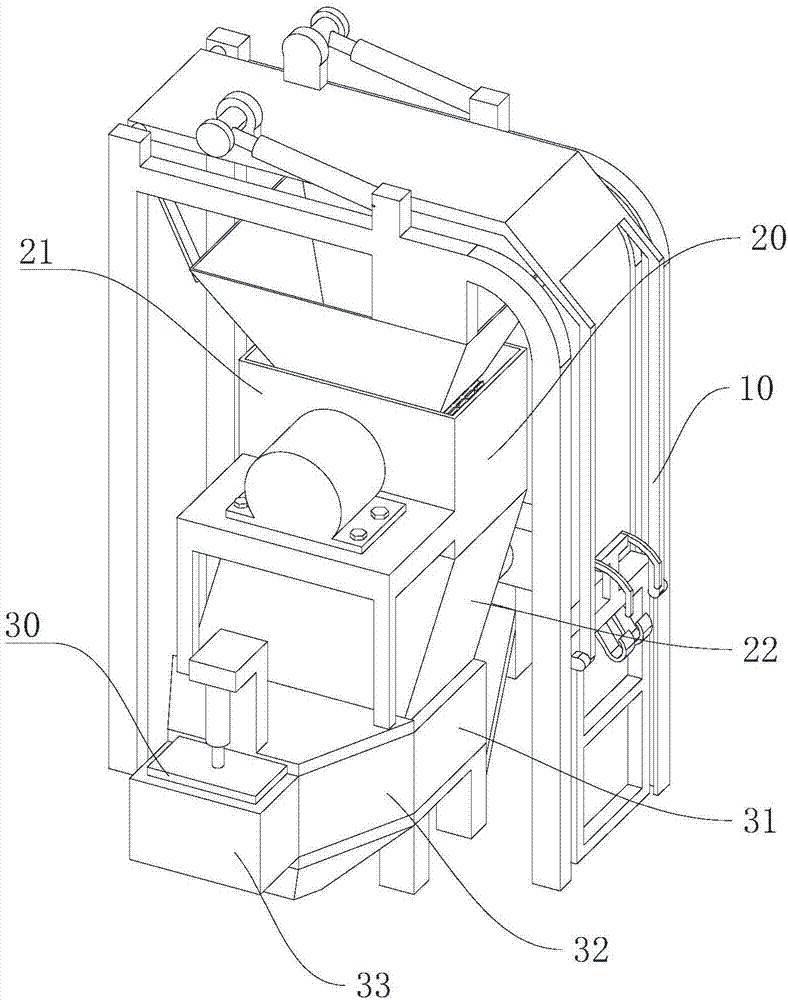

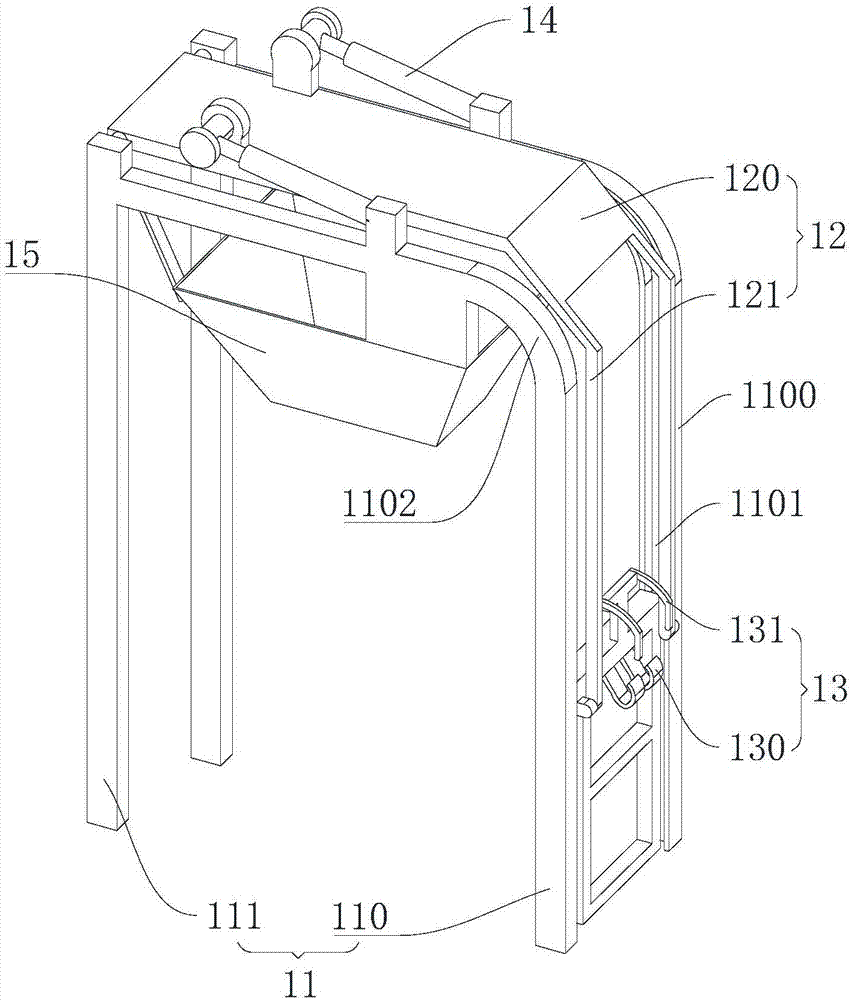

[0025] Please refer to figure 1 As shown, the embodiment of the present invention provides an environment-friendly garbage recovery treatment device, including a feeding mechanism 10, a crushing mechanism 20 and a pressing mechanism 30. The function of the feeding mechanism 10 is to transport the garbage from the garbage dump site to the crushing The top of the mechanism 20, and the rubbish is dumped into the crushing mechanism 20. The function of the crushing mechanism 20 is to crush the garbage and transport it to the pressing mechanism 30. The function of the pressing mechanism 30 is to compress the volume of the garbage, squeeze out the moisture in the garbage, and reduce the weight of the garbage.

[0026] Specifically, please refer to figure 2 As shown, the crushing mechanism 20 is arranged between the feeding mechanism 10 and the pressing mechanism 30 , and the crushing mechanism 20 not only plays the role of crushing garbage, but also plays the role of connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com