Automatic cover safety valve equipment and safety valve for battery production

A technology for safety valves and batteries, which is applied in the construction of lead-acid batteries, lead-acid batteries, battery pack components, etc. It can solve problems that affect product quality stability, low efficiency, and different depths of safety valve covers, and solve the problems that cannot be automatically Normal feeding problem, easy to use, avoid sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

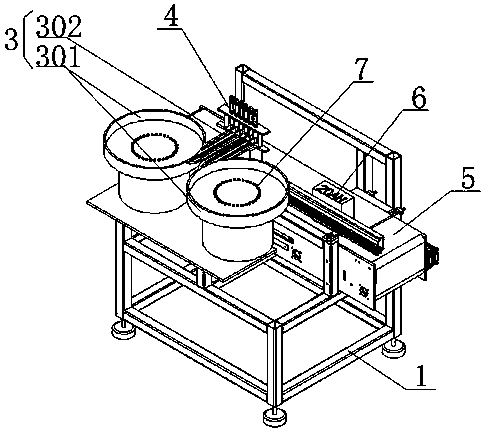

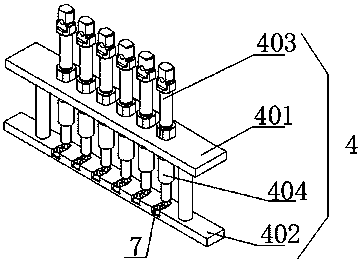

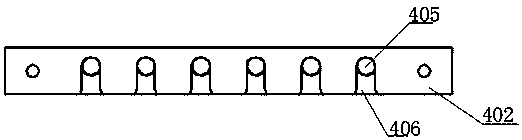

[0033] This embodiment provides an automatic cover safety valve device for battery production, such as Figures 1 to 5 As shown, it is mainly composed of a frame 1 and a safety valve feeding device 3 arranged on the frame 1, a safety valve cover device 4 and a battery delivery device 5. The safety valve feeding device 3 consists of two vibrating plates 301 and six conveying devices. The track 302 is composed of, each vibrating plate 301 is connected with the entrance of three conveying tracks 302, and the outlets of the six transporting tracks 302 are all connected with the safety valve cover device 4. The vibrating plate 301 in this embodiment is specially made, and the vibrating plate 301 The treatment process includes disc twill, channel embossing, and Teflon spraying to ensure continuous and stable material supply to the safety valve 7; the safety valve cap pressing device 4 consists of a base plate 401, a safety valve positioning mold 402, six cap pressing cylinders 403 an...

Embodiment approach 2

[0038] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, since the position of the safety valve cover device 4 is fixed, that is, the position of the safety valve positioning mold 402 is fixed, the equipment can only be used in One size of the battery 6 to be pressed has a narrow application range, and if there is a positioning deviation, it cannot be calibrated by adjusting the position of the safety valve positioning mold 402 , but this embodiment can effectively solve the above defects.

[0039] Specifically, in this embodiment, as Figure 8 and 9 , the safety valve cover device 4 also has an adjustment plate 407 and two adjustment rods 408, one side of the adjustment plate 407 is fixed on the frame 1, and the other offers two waist-shaped through holes 409, the safety valve cover device 4 The base plate 401 in the center is fixed to the adjustment plate 407 through two waist-shaped through holes 409 respectively throug...

Embodiment approach 3

[0042] This embodiment is a further improvement of Embodiment 2. The main improvement is that in Embodiment 2, the battery 6 to be pressed is only smoothly transported to the bottom of the safety valve positioning mold 402 through the battery delivery device 5 , and the safety valve needs to be After the safety valve positioning through hole 406 on the positioning mold 402 is aligned with each acid injection hole on the battery 6 to be covered, the automatic pressing of the safety valve 7 can be more effectively realized. Therefore, only the battery delivery device 5 At this time, when the battery 6 to be pressed is located below the safety valve positioning mold 402, the battery delivery device 5 needs to be suspended until the safety valve pressing device 4 presses the safety valve 7 onto the acid injection holes of the battery 6 to be pressed. , the delivery mechanism can be started again to transport the installed battery to the next process, and at the same time move the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com