Special continuous feeding device for mobile phone aluminum plate grinding for double ended grinding machine

A double-face grinder and feeding device technology, which is applied to machine tools suitable for grinding workpiece planes, parts of grinding machine tools, grinding machines, etc., can solve the problems of low product qualification rate, low production efficiency, and high labor costs, and achieve guaranteed The effect of qualification rate, feeding stability, processing efficiency and automation level improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

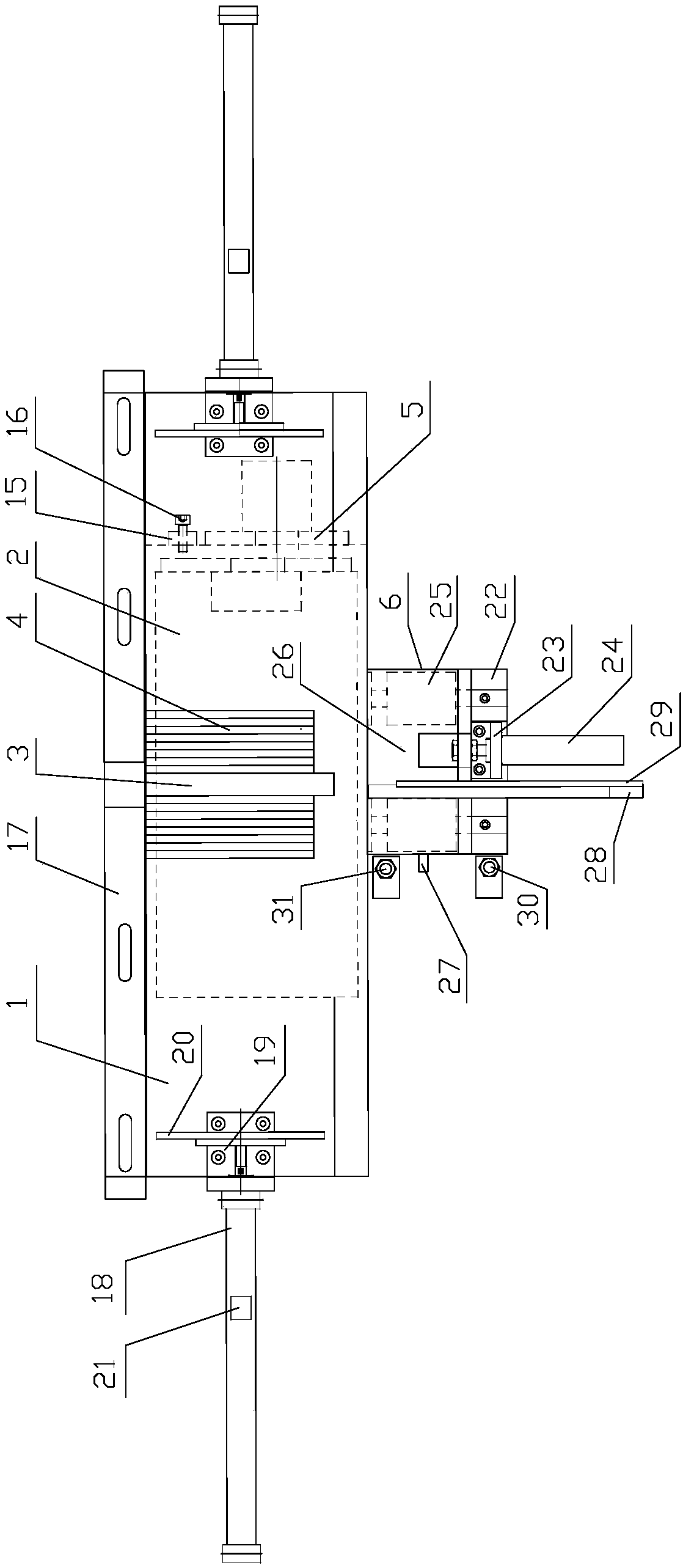

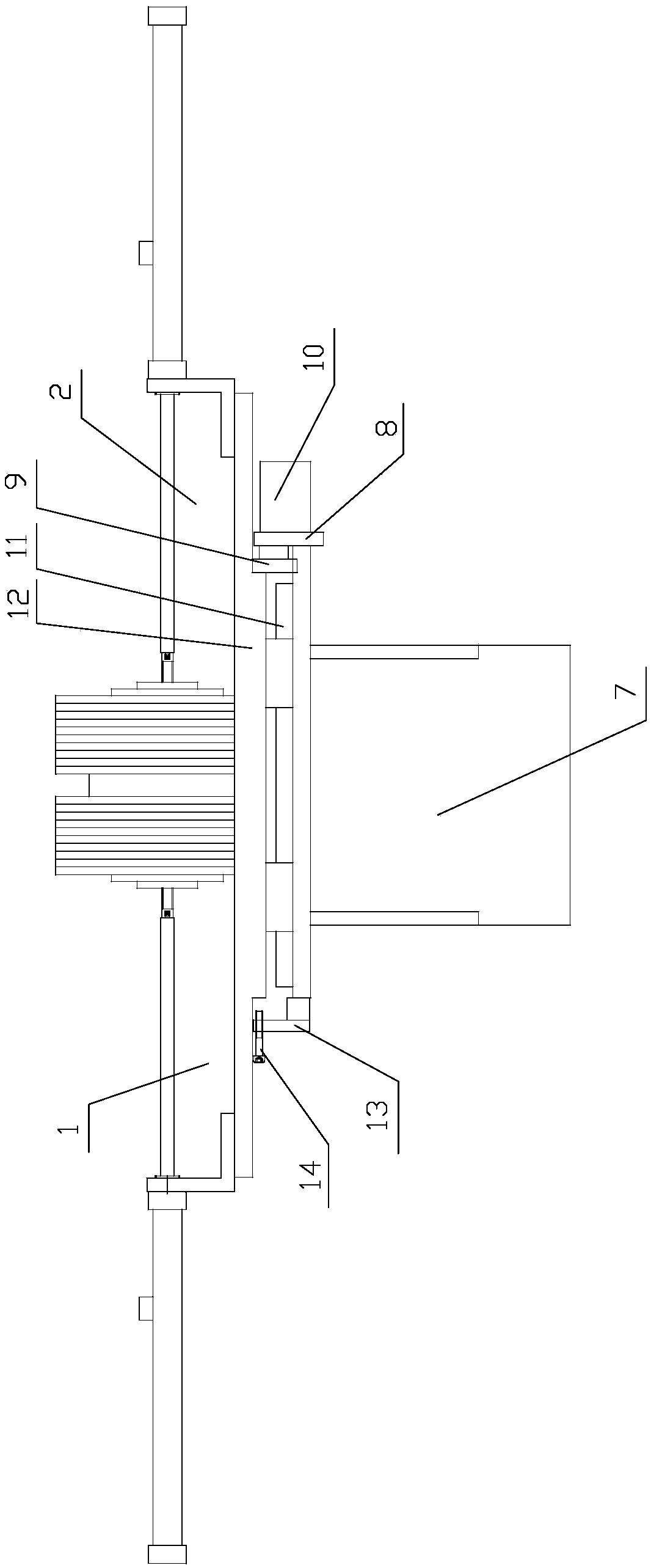

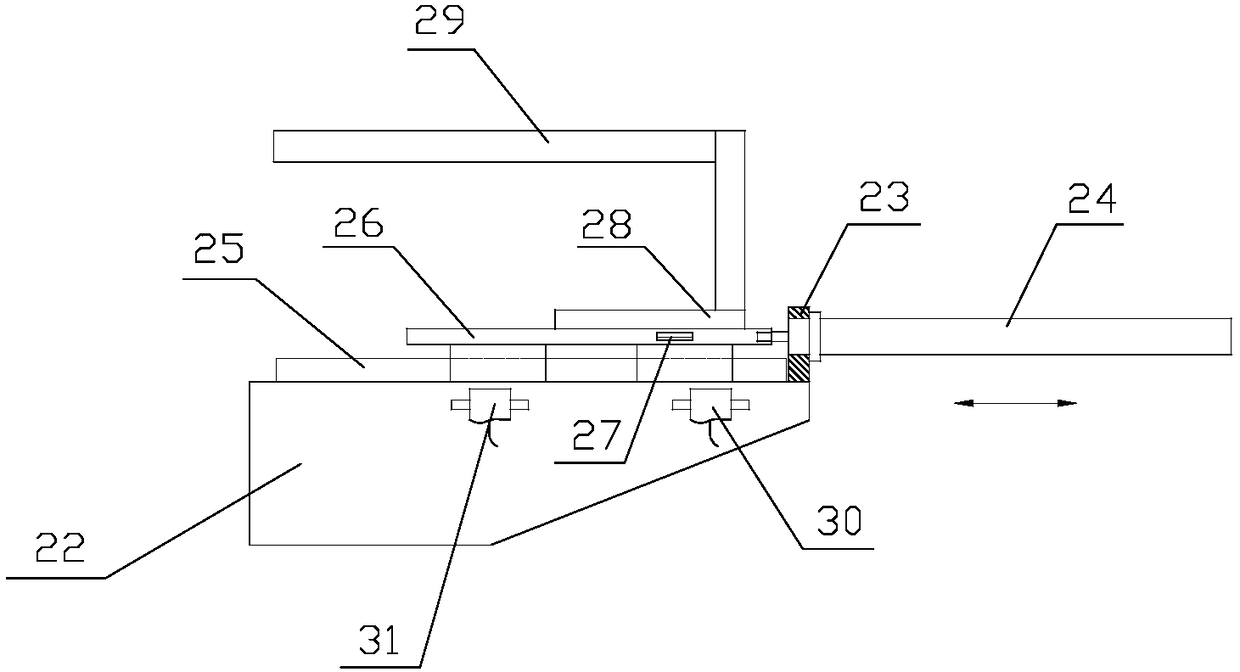

[0015] Such as figure 1 , figure 2 and image 3 As shown, the continuous feeding device of the present invention is provided with a first base 7 and a second base 22 for grinding special mobile phone aluminum plates for double-end grinding machines. The first base 7 is located behind the second base 22. The first base 7 and the second The base 22 can be set as one body or separately. The first base 7 is provided with a horizontal reversing mechanism 5 that can reciprocate and slide left and right, and the second base 22 is provided with a longitudinal propulsion mechanism 6 that can reciprocate and slide back and forth. Direction is vertical. The horizontal reversing mechanism 5 is provided with a partition 3, and the left and right sides of the partition 3 are symmetrically provided with an A feed trough 1 and a B feed chute 2, and the A f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com