Automatic feeding device of particle crumble blank

An automatic feeding and crushing technology, which is applied in the field of clay molds, can solve the problems of industrial development obstacles, low degree of automation, and inadaptability to the market economic model, and achieve the effect of solving intermittent operation and the inability to increase the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

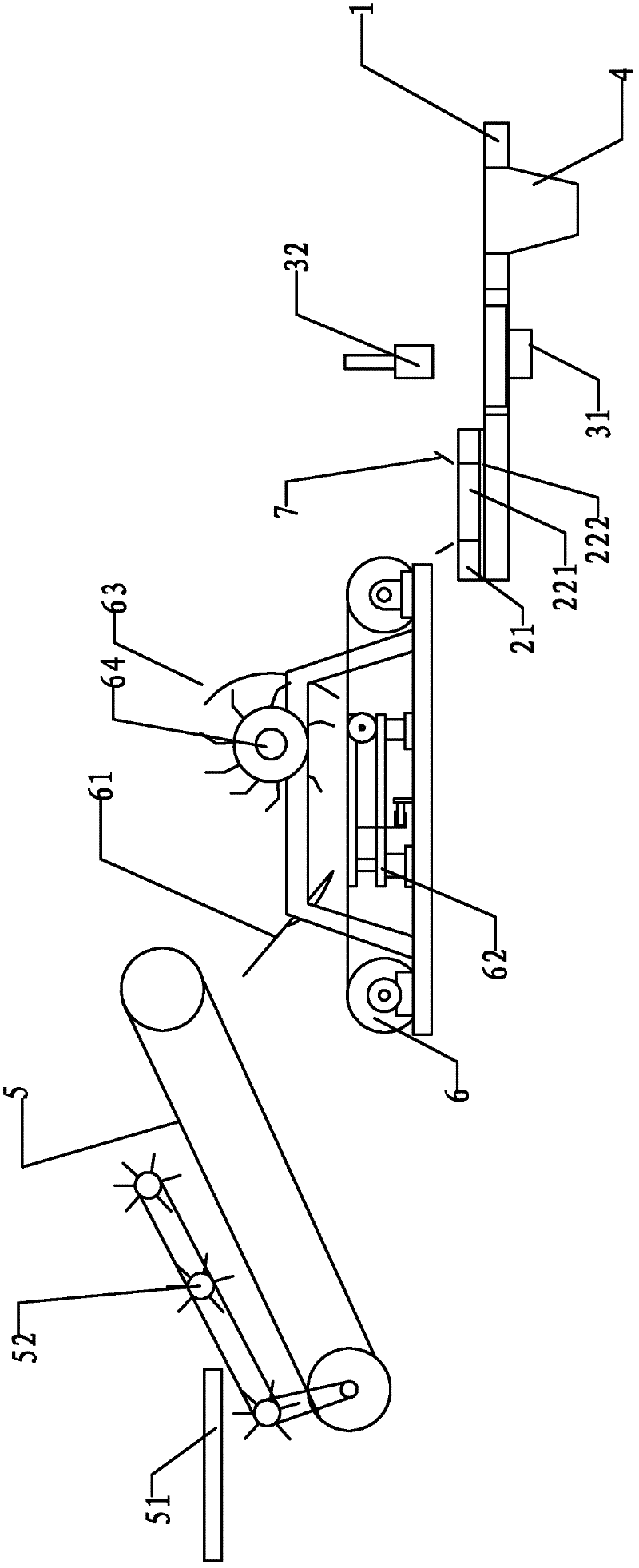

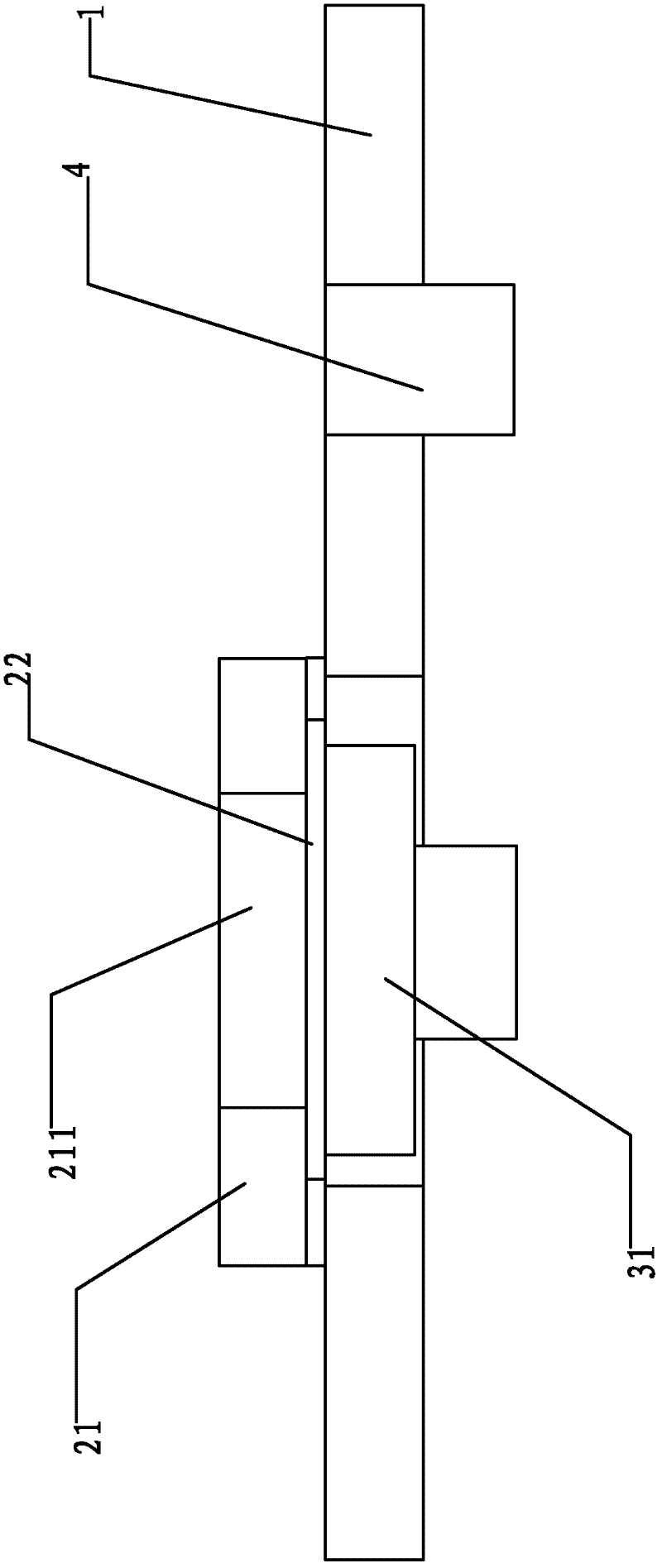

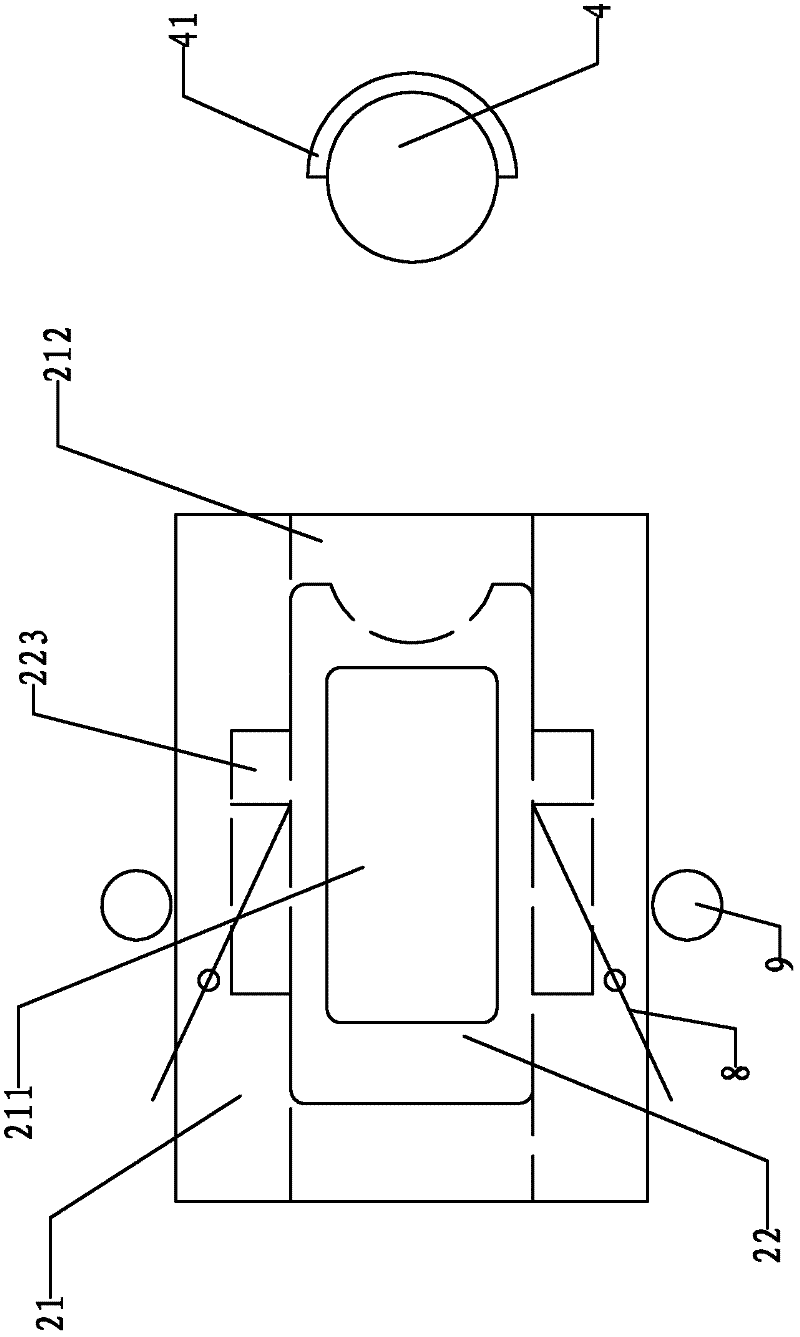

[0018] Refer to attached figure 1 , attached figure 2 and attached image 3 , a kind of automatic feeding device for granular powder blanks of the present invention as shown in the accompanying drawings, comprising a machine platform 1, a material control device and a sliding material plate, the machine platform 1 is provided with a mold hole 4, and the sliding material plate slides through the feeding position , material control device and mold hole 4, the sliding material plate includes a measuring groove plate 21 and a sliding plate 22, and the measuring groove plate 21 is provided with a plurality of measuring grooves 211 for accommodating the particle powder blanks side by side, and the sliding plate 22 is arranged on the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com