Full-automatic mask ear belt welding machine

A mask and earband technology, applied in the field of automatic mask earband welding machine, can solve the problems of affecting the speed of the whole machine, difficulty and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is implemented in the following ways:

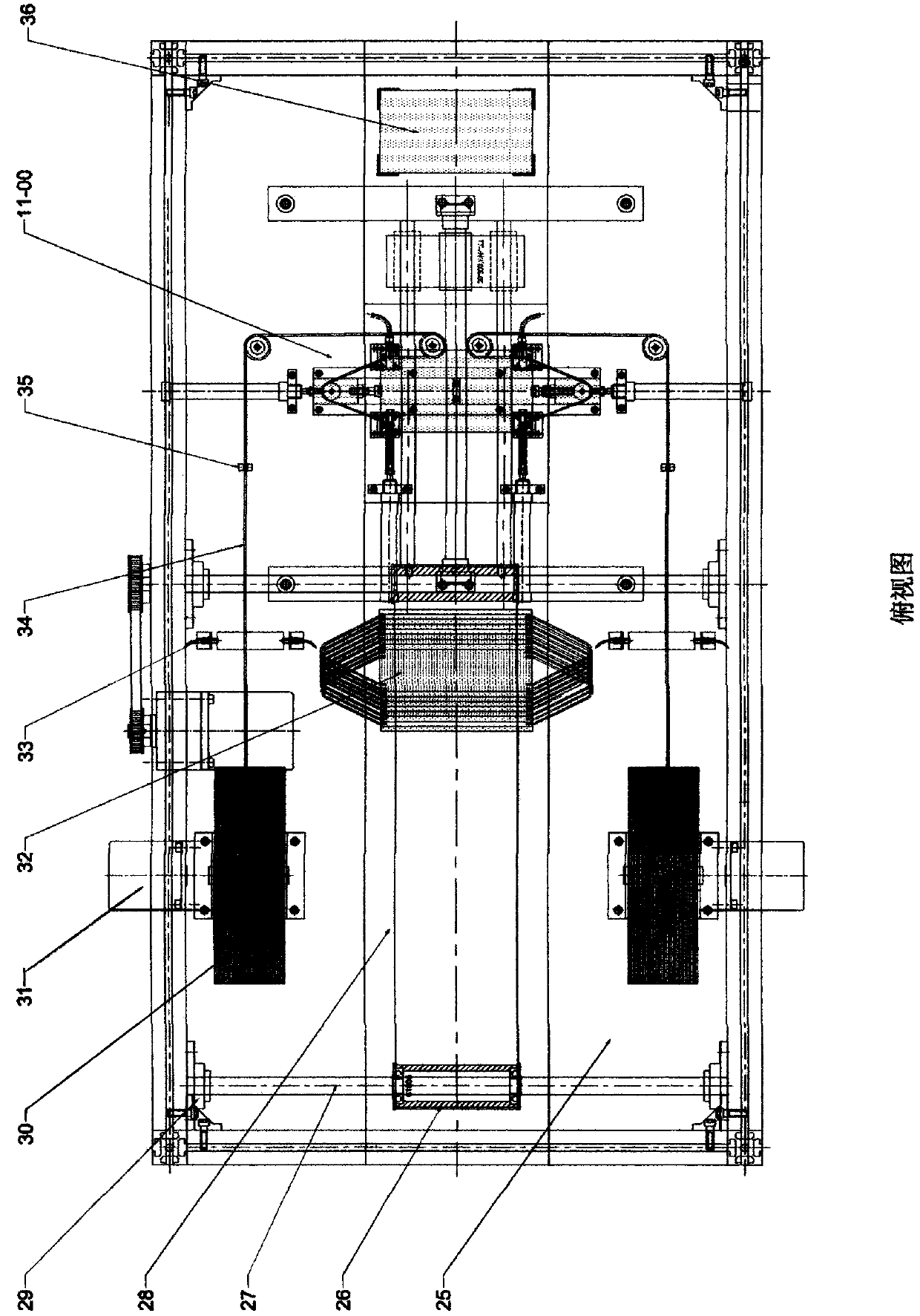

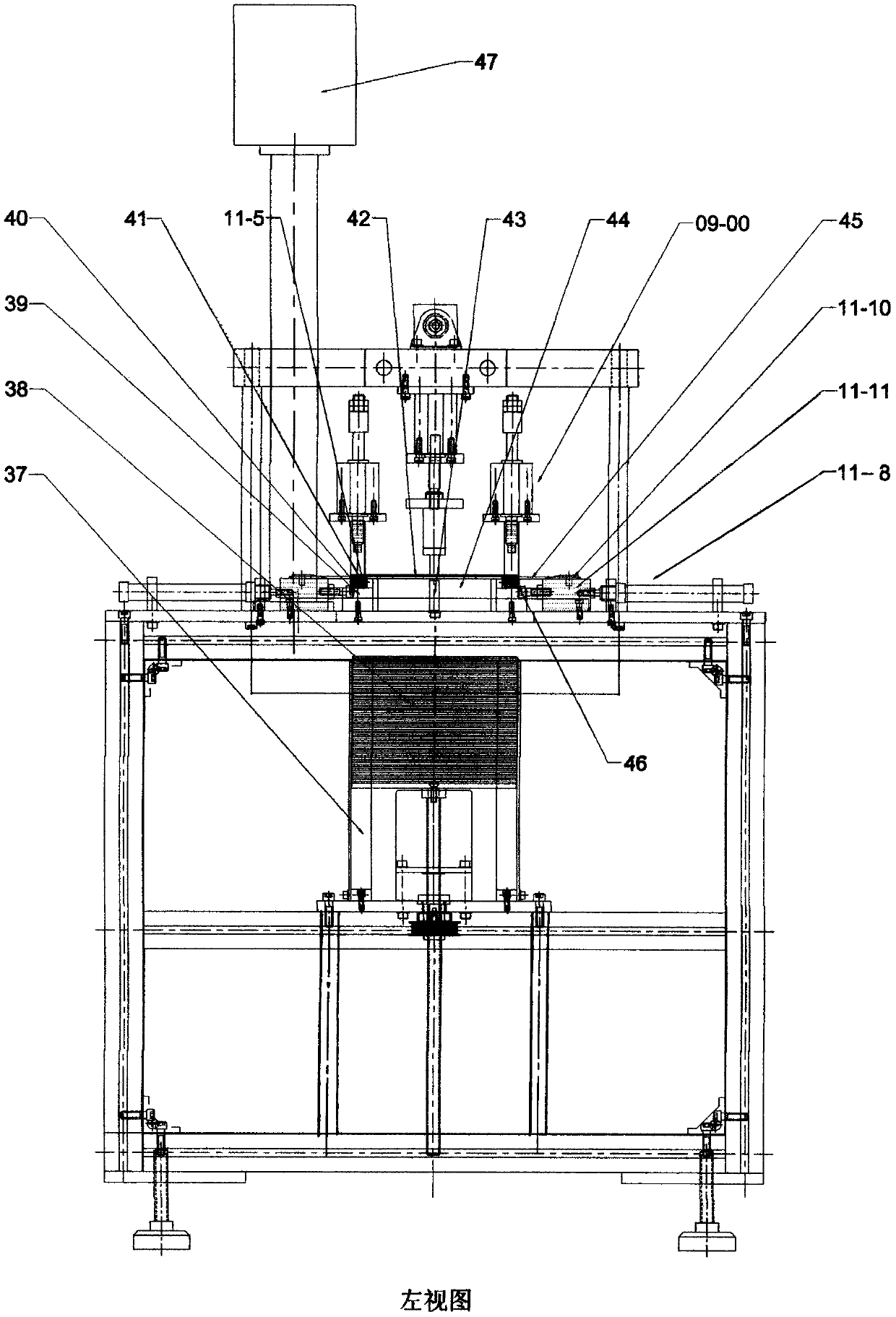

[0016] The invention is composed of: 1. Mask lifting and feeding part, 2. Mask feeding manipulator part, 3. Ear belt feeding part, 4. Ear belt welding part, 5. Automatic feeding part, 6. Machine, 7. Pneumatic system , 8. PLC electrical control part.

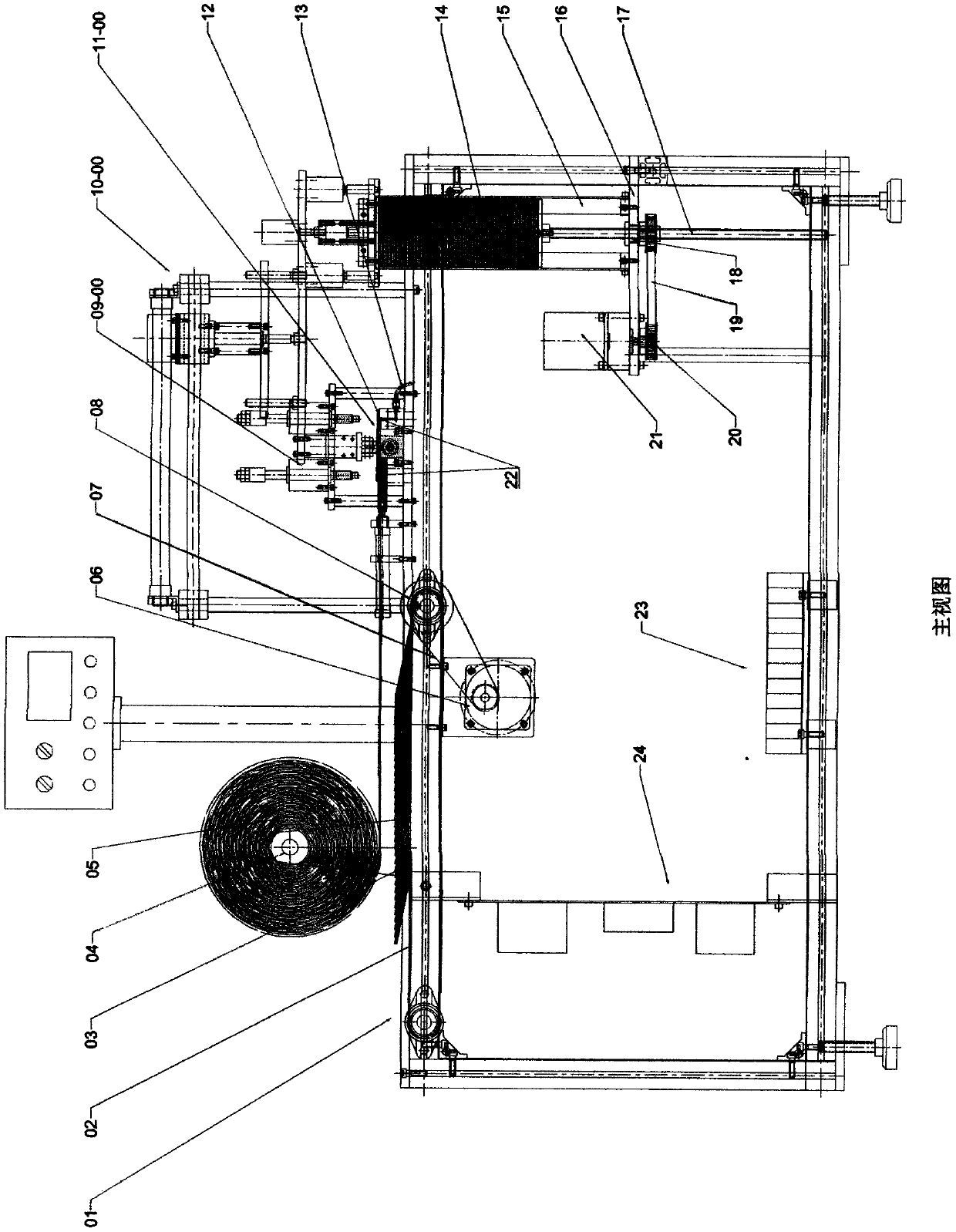

[0017] 1. The present invention uses stacked masks for automatic lifting and feeding. It is installed on the right side of the machine. It consists of: 14 (mask sheet), 15 (support), 16 (support plate), 17 (screw) , 18 (spin mother), 19 (belt), two 20 (pulley), 21 (motor) composition, such as figure 1 Shown.

[0018] 2. The mask feeding is clamped by two manipulators, one feeding and the other unloading. It is installed on the right side of the machine. The feeding part is composed of: 10-12 (reclaiming cylinder), 10-13 (supporting plate), 10 -14 (supporting plate), 2 10-15 (discharge cylinder), 2 10-16 (guide rod), 2 10-17 (reclaiming plate), 10-18 (drive block), 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com