Helical main shaft and water-entrained feather wringing dehydrator

A screw spindle and dehydrator technology, applied in the direction of dryer, drying, drying solid materials, etc., can solve the problems of long production cycle, affecting production efficiency, easy to block and slip, etc., achieve reasonable structural design, increase extrusion Drying effect, increasing pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

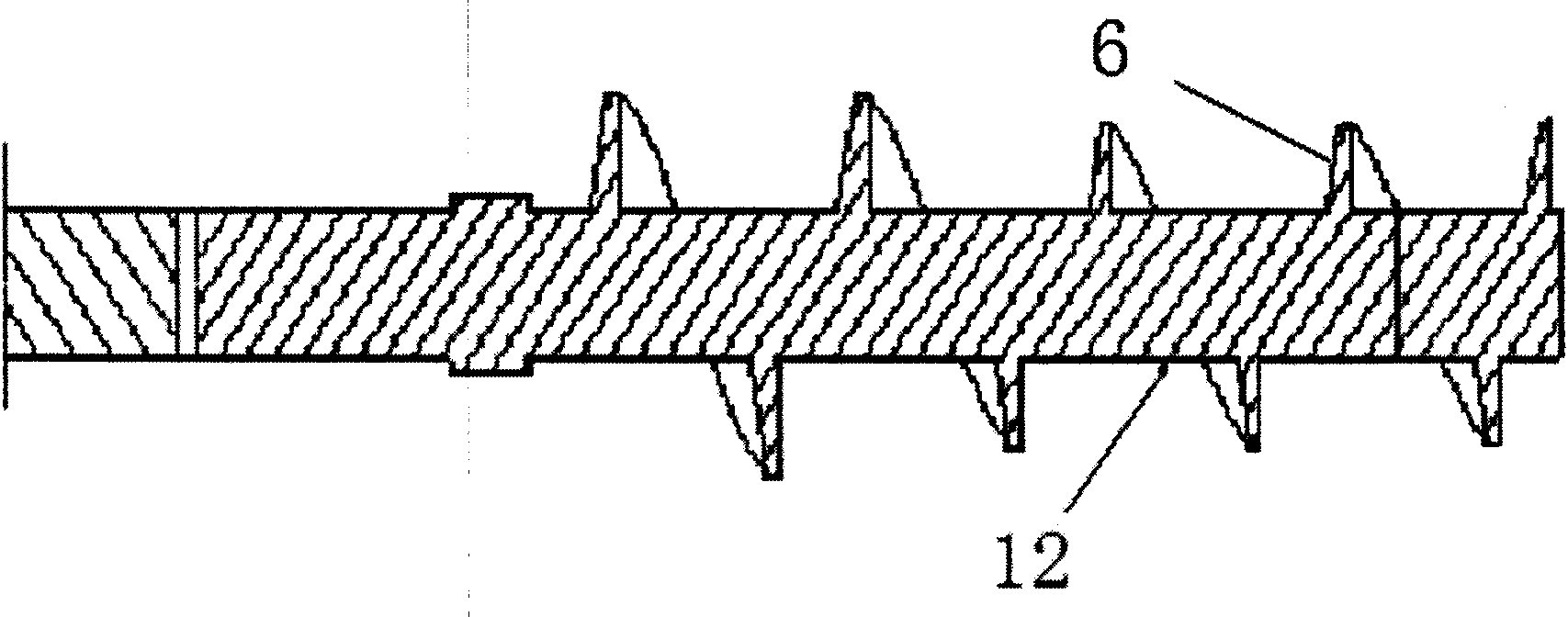

[0017] A screw spindle in this embodiment is special in that screw blades 6 with gradually decreasing pitch are arranged on the peripheral shaft wall. cloth;

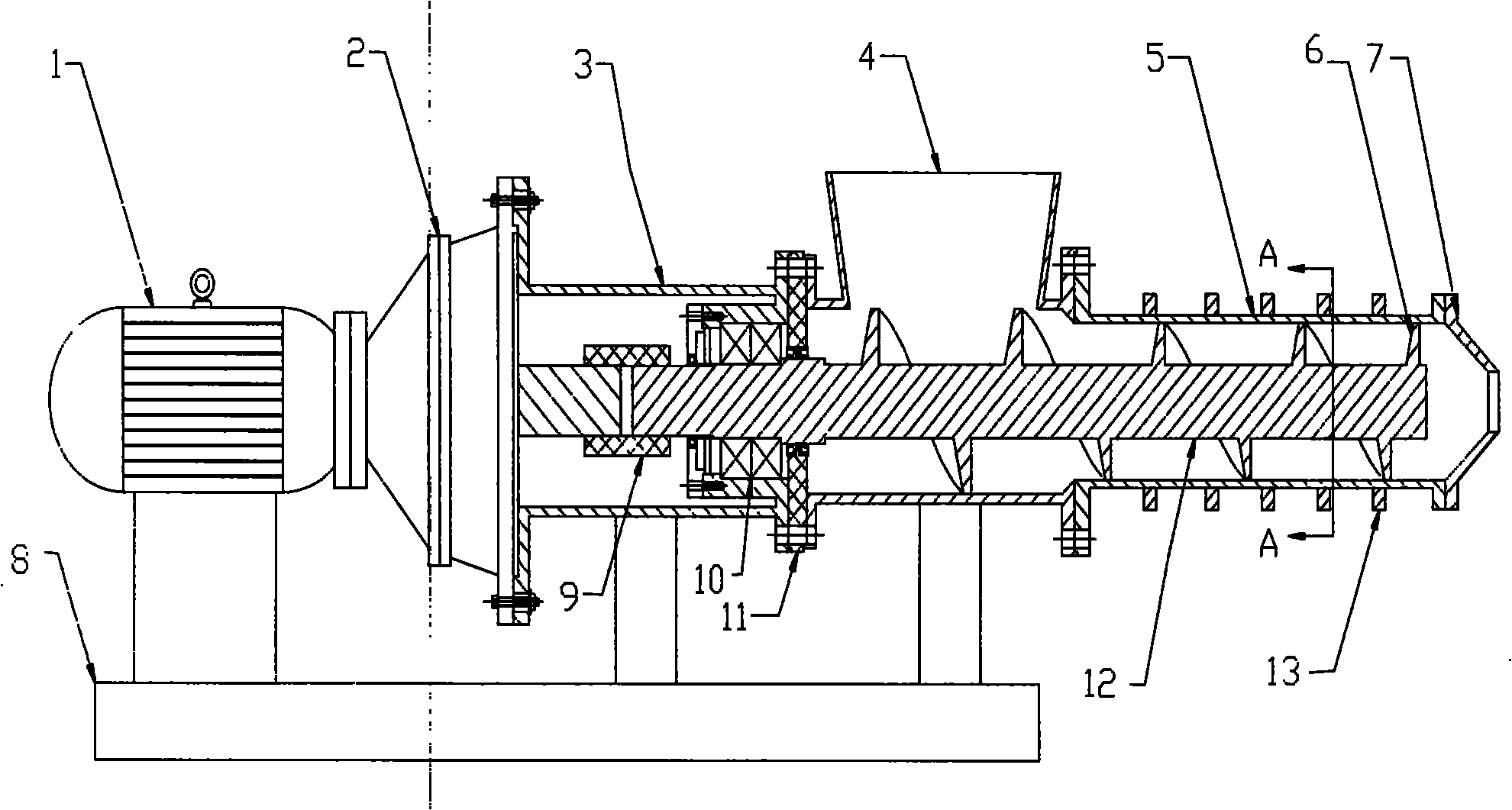

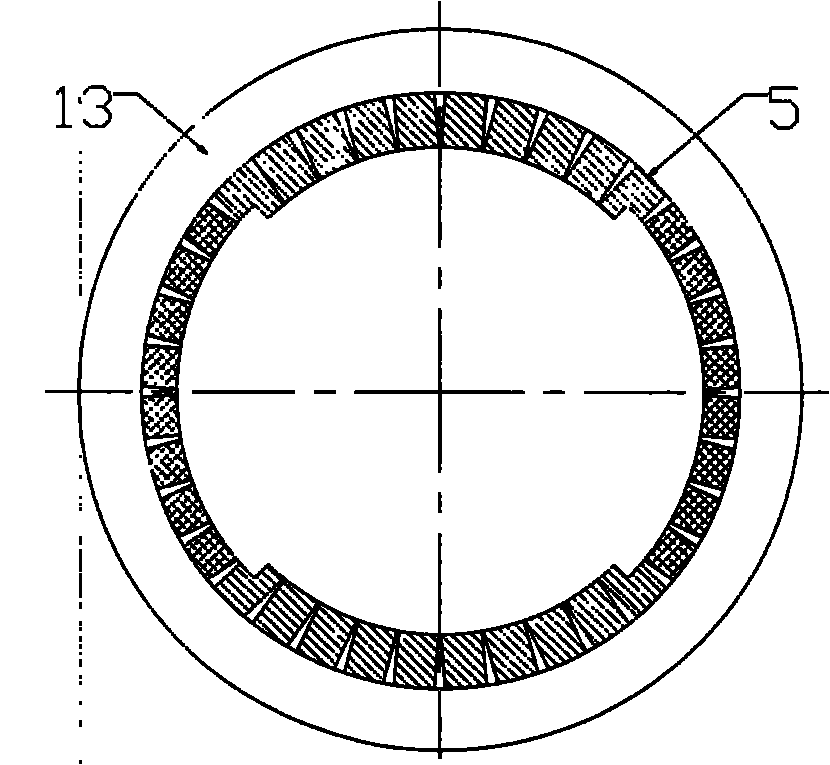

[0018] A water-feather squeeze-drying dehydrator in this embodiment comprises a three-phase asynchronous motor 1, and the three-phase asynchronous motor 1 is connected with a cycloid reducer 2 through a transmission connection with a cycloid reducer 9 through a coupling 9. The screw main shaft 12, the feeding box 4 is arranged above the screw main shaft 12, and the periphery of the screw main shaft 12 is provided with a pressing chamber formed by pressing strips 5 of different cross-sectional sizes arranged at intervals, and the port of the pressing chamber is installed with a The tapered die head 7, screw blades 6 with gradually decreasing pitch are arranged on the peripheral shaft wall of the screw main shaft 12, and the outer diameter of the screw blades 6 located inside the feeding box 4 is larger than that of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com