Automatic feeding and discharging device for assisting in plastic uptake

A technology for unloading and plastic sheets, applied in the field of automatic loading and unloading devices, can solve the problems of low production efficiency, high difficulty and high blister cost of plastic hard sheets, and achieve the effect of reducing the cost of single-piece blister molding and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

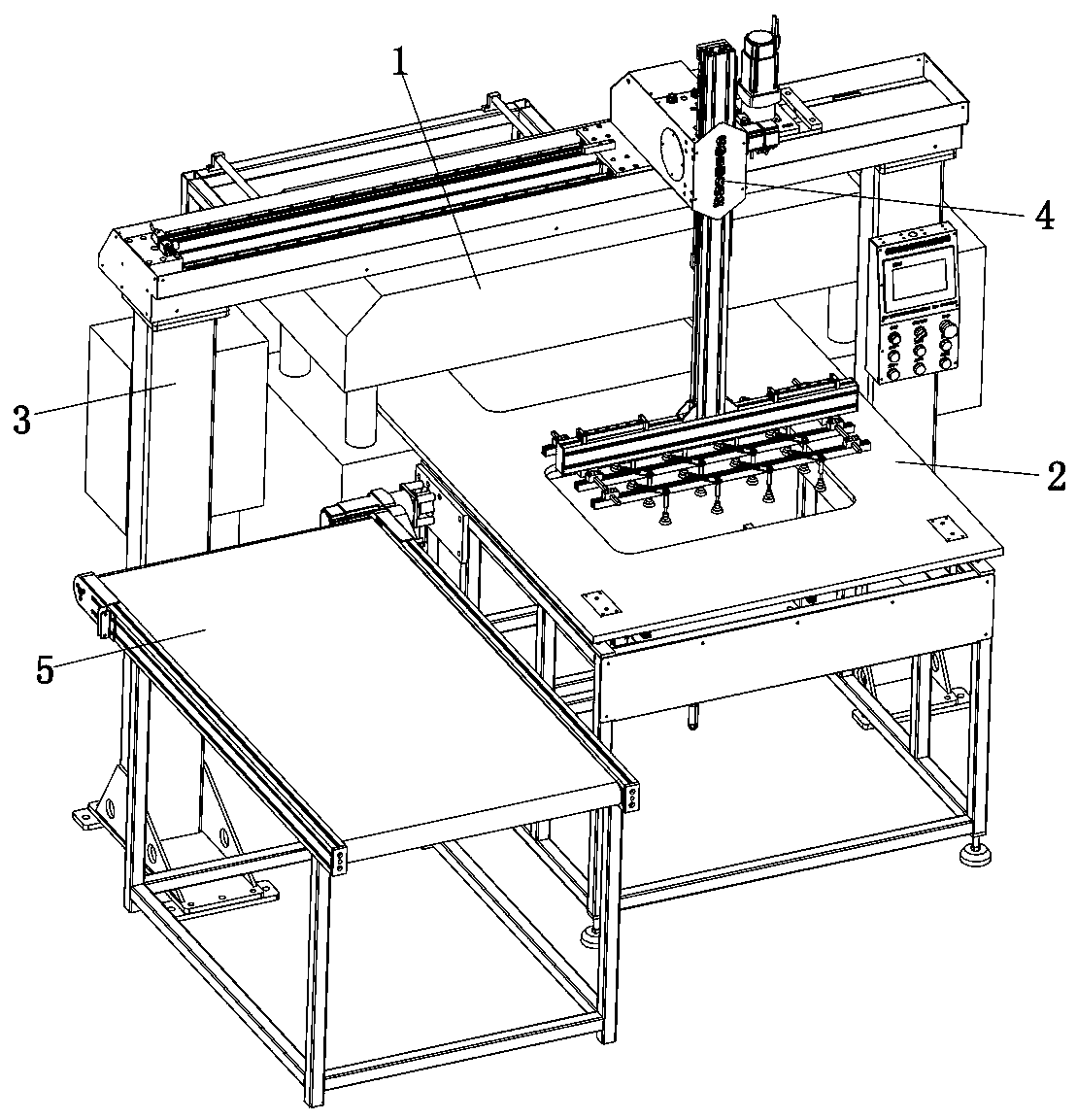

[0041] Embodiment 1: as Figure 1 to Figure 15 As shown, the technical scheme adopted by the present invention is as follows: an automatic loading and unloading device for assisting plastic suction, comprising a plastic suction mechanism 1, a material pushing mechanism 2, a feeding and discharging mechanism and a material blanking mechanism 5, wherein the above-mentioned pushing material The mechanism 2 is arranged horizontally, and the material carrier plate 25 on the top of the pushing mechanism 2 slides back and forth in a straight line; The upper part and the lower part; the above-mentioned taking-and-discharging mechanism straddles the top of the pushing mechanism 2 and extends to one side of the pushing mechanism 2; the above-mentioned unloading mechanism 5 is arranged on one side of the pushing mechanism 2 and extends to the taking-and-place The bottom of the material mechanism; after the plastic sheet to be blistered is loaded on the material carrier plate 25 of the pu...

Embodiment 2

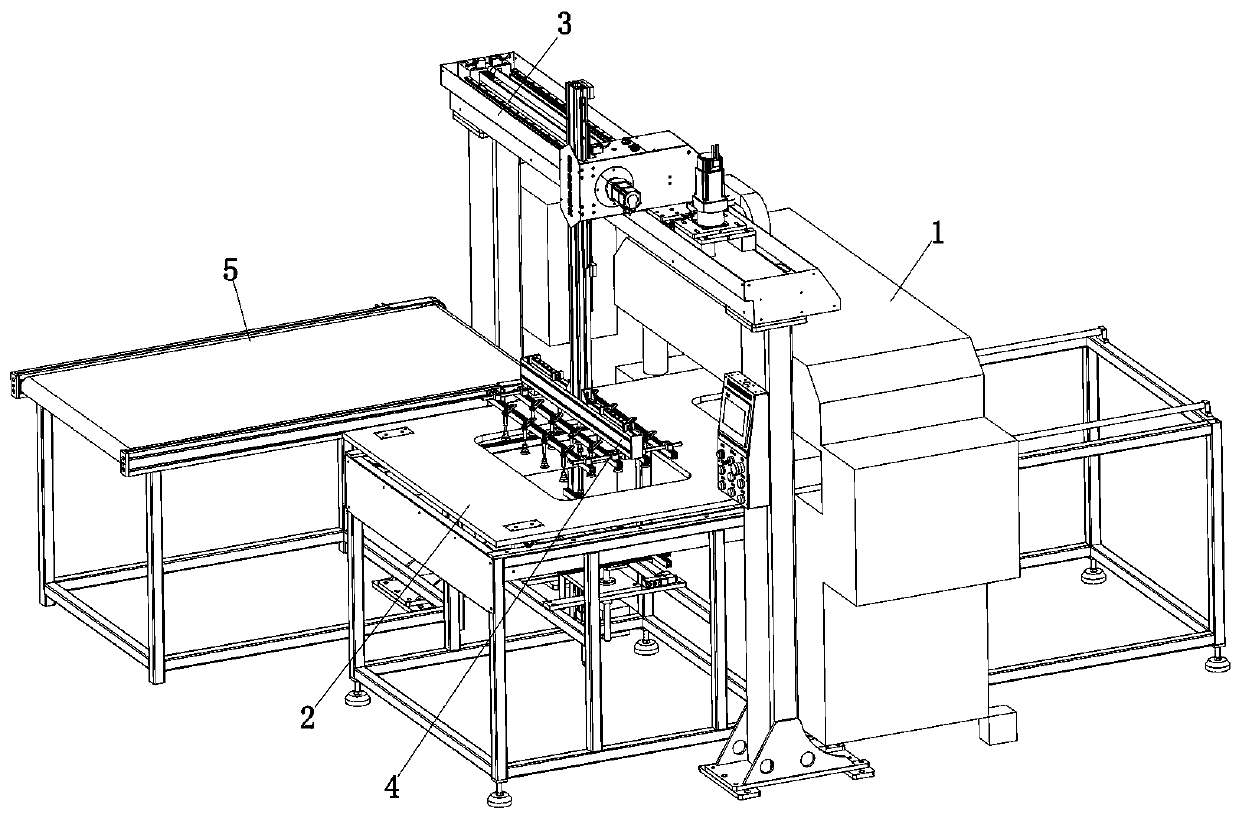

[0051] Embodiment 2: as Figure 16 to Figure 17 As shown, it is Embodiment 2 of the present invention. The difference between this embodiment and Embodiment 1 is that two take-and-discharge mechanisms and two unloading mechanisms are used, and the two take-and-discharge mechanisms are respectively arranged on both sides of the blister mechanism. The loading and unloading mechanism straddles the first bracket or the second bracket, and extends to the outside of the first bracket or the second bracket; the two unloading mechanisms are respectively arranged on the first bracket and the second bracket corresponding to the two loading and unloading mechanisms outside. This embodiment is different from the method of loading materials from one side of the second bracket in Example 1. Both sides of the first bracket and the second bracket can be fed simultaneously and independently. When plasticizing, just push the material on the other side back to the bottom of the pick-up and disc...

Embodiment 3

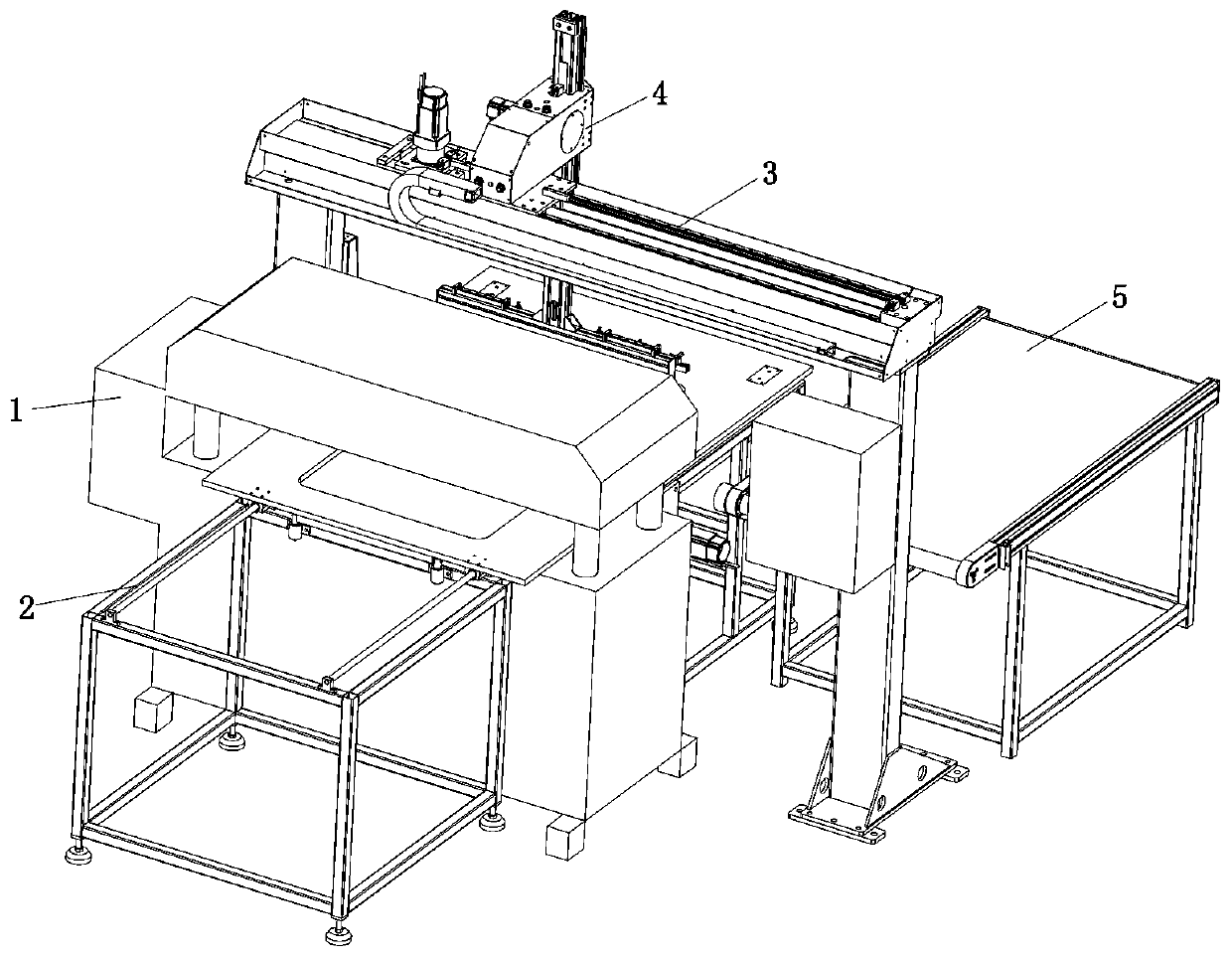

[0052] Embodiment 3: as Figure 18 to Figure 19 Shown, be embodiment 3 of the present invention, this embodiment has saved pusher mechanism on the basis of embodiment 1, this kind of situation can exist in actual processing, so enumerate here; Adopt this embodiment only It can complete semi-automatic blistering, that is, the same as in embodiment 1, the automatic blanking of blister products is completed through the pick-up and discharge mechanism; Push it into the blister mechanism, pull out the carrier after the blister is completed, and the pick-up and discharge mechanism takes the finished product from the carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com