Method for producing recombinant composite board by using waste wood

A technology of composite board and manufacturing method, which is applied in the direction of manufacturing tools, wood layered products, wood processing appliances, etc., to achieve the effects of smooth surface, improved comprehensive utilization rate, and regular format

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

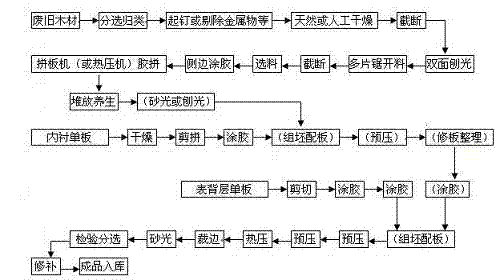

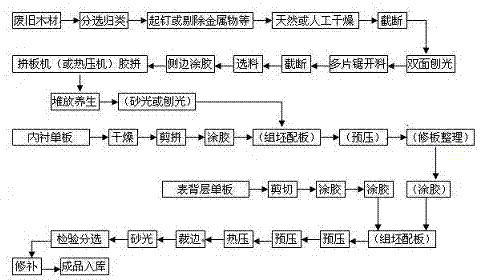

[0027] Referring to the accompanying drawings, describe the manufacturing method of using waste wood to produce recombined composite boards:

[0028] (1) Preparation of the core plate,

[0029] ① Material type of core plate

[0030] Recycled waste wood has a variety of species. Before processing, it must be classified according to tree species. Different tree species or tree species with dissimilar properties cannot be mixed in the same core board. The material selection is easy to process, and the core strip is easy to flatten. Tree species with small shrinkage and deformation are processed and reorganized.

[0031] ②Requirements for core plate

[0032] The thickness of the control core plate accounts for 60-80% of the total thickness of the recombined composite plate, and the thickness should be consistent. For core strips assembled into core boards, it is usually more appropriate to use wooden strips with a thickness-to-width ratio of 1:1.5~2, and the thickness tolerance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com