Automatic feeding device of zirconium electrode hydraulic machine

A technology of automatic feeding and hydraulic press, applied in the direction of presses, manufacturing tools, etc., can solve the problems of manual implementation, unsatisfactory, inconvenient operation, etc., and achieve the effect of improving production efficiency and solving the problem of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

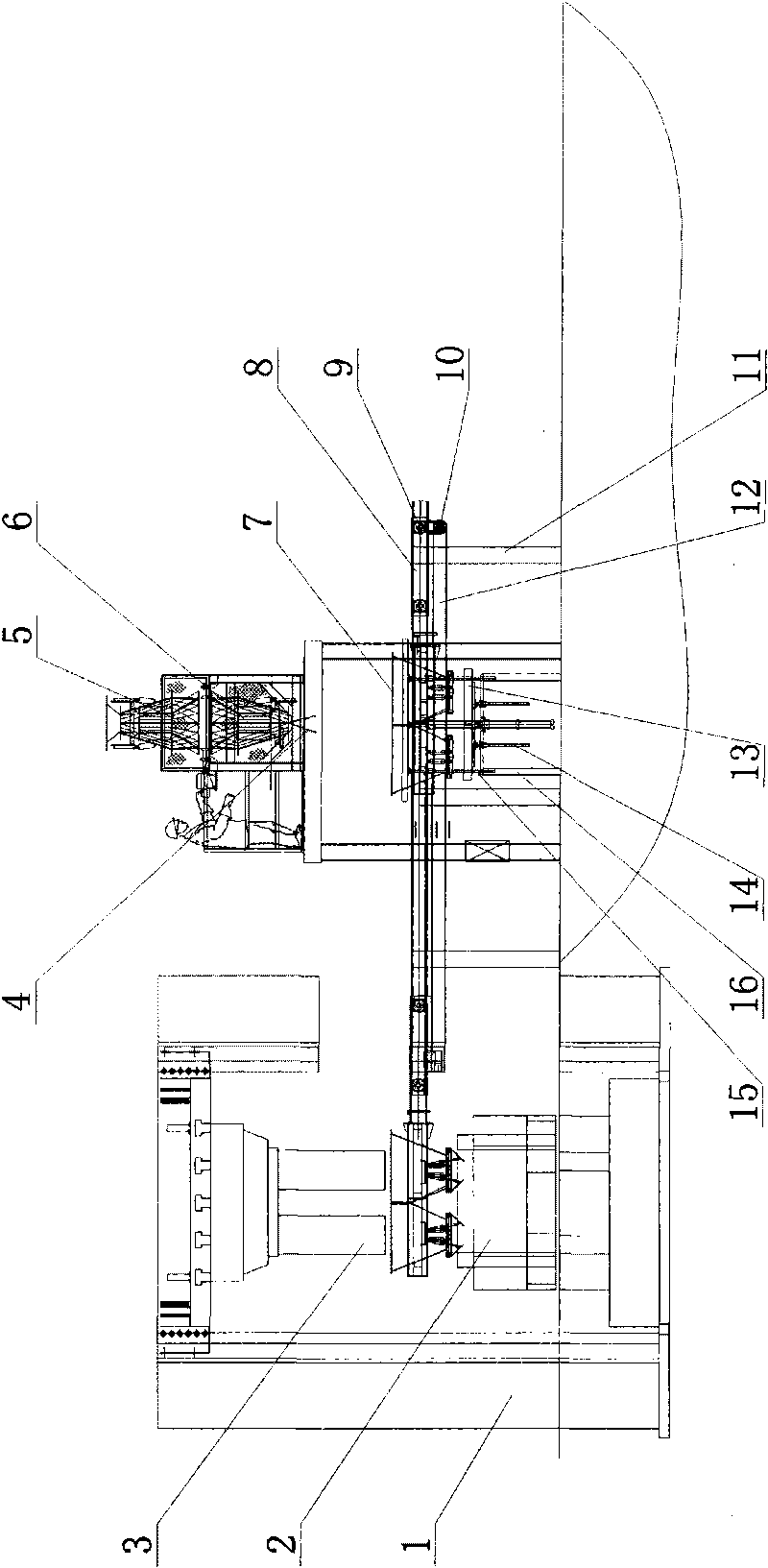

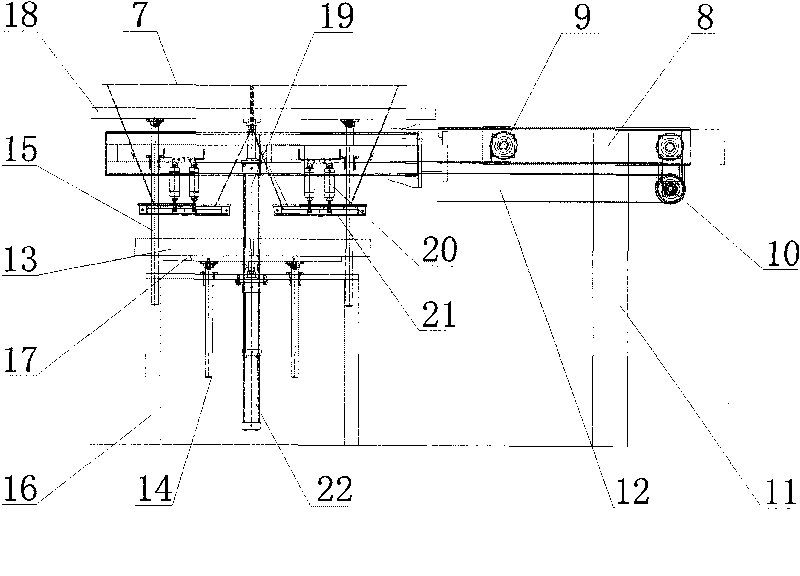

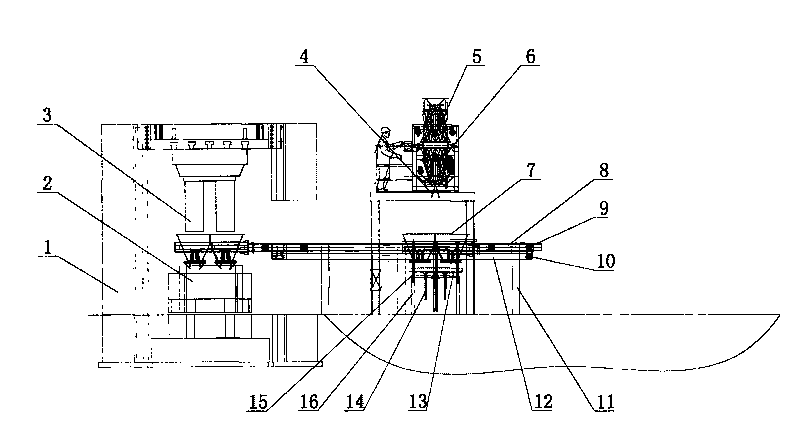

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] Such as figure 1 , figure 2 As shown, the mold 2 is installed on the workbench of the hydraulic press 1, the pressure head 3 is installed on the slider of the hydraulic press, a frame 11 is installed on the side of the hydraulic press, a guide rail 12 is installed on the frame, and a moving rail is installed on the guide rail. Dolly 8 and its roller 9 and the speed reducer 10 of driving roller. A frame-shaped supporting plate 18 is installed on the trolley, and two rectangular hoppers 7 and their hopper jacking mechanisms are installed side by side in the middle of the supporting plate. An openable sealing plate 21 and its hydraulic cylinder 20 are installed on the bottom of the hopper. Electronic weighing device with hopper install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com