Drill rod machining automatic feeding system and method

A technology of automatic feeding and drilling, applied in metal processing, automatic control devices, metal processing equipment, etc., can solve the problems of heavy weight (weight over 30Kg, long length, etc., to save the floor space of workshop equipment, improve production Efficiency and the effect of ensuring the success rate of material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

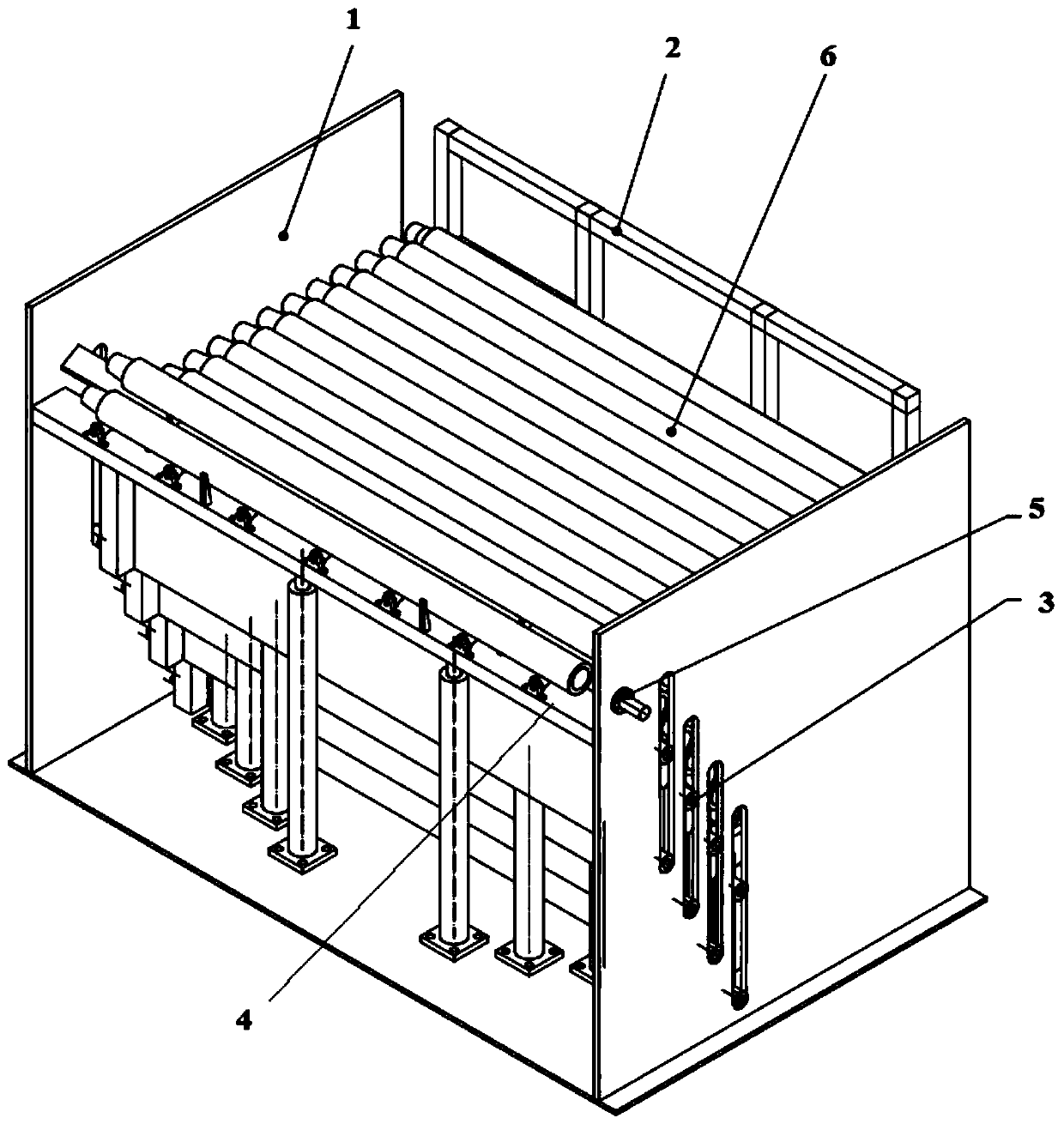

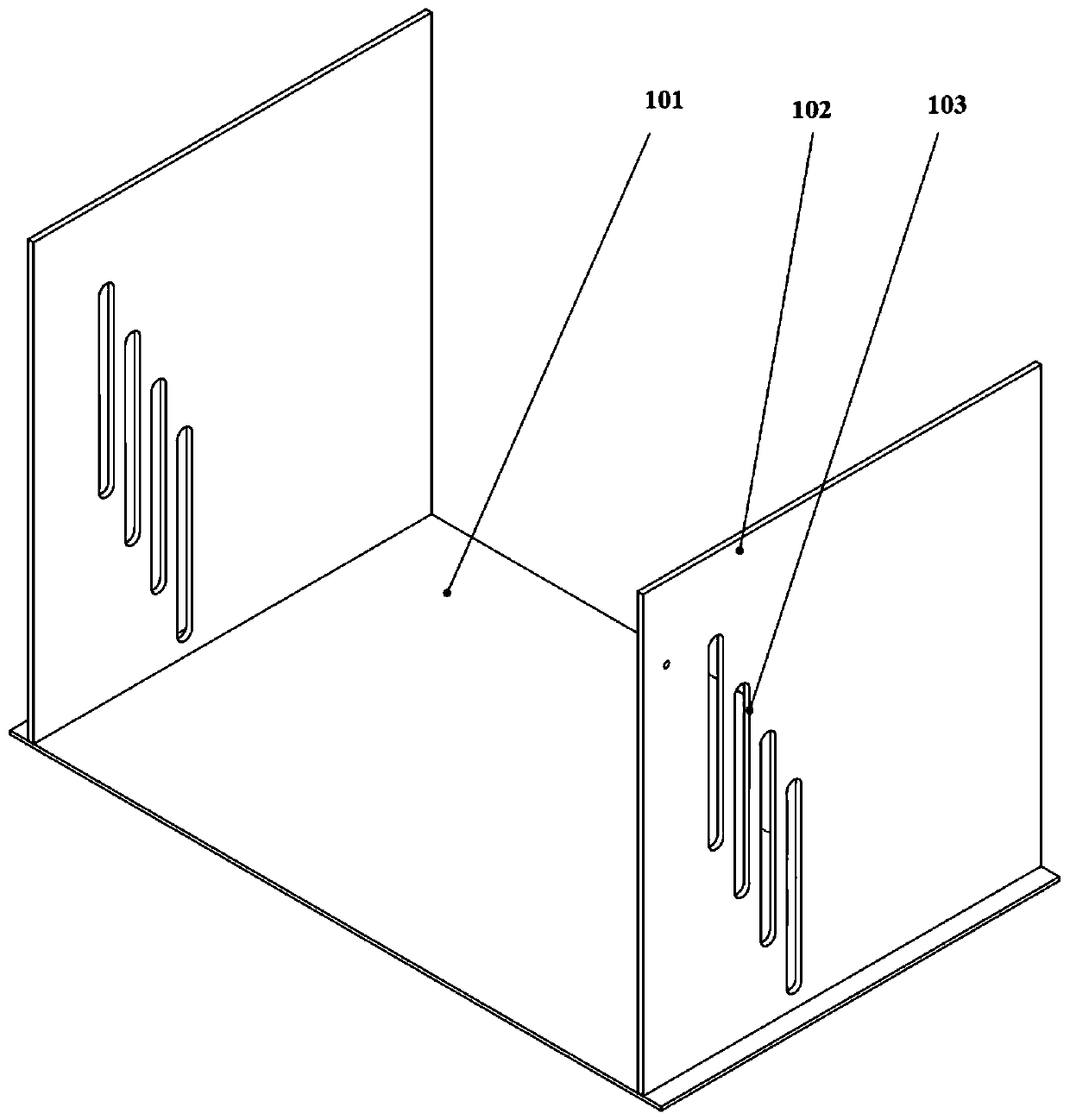

[0059] Such as Figure 1 to Figure 9 As shown, this embodiment provides an automatic feeding system for drill pipe processing, including a frame 1, a drill pipe box 2, a step material distribution device 3, a buffer device 4 and a positioning device 5; the frame 1 includes a frame bottom plate 101 And the two frame side plates 102 that are vertically fixed on the two ends of the frame bottom plate 101 and are parallel to each other; Between, and the above-mentioned components are equipped with sensors.

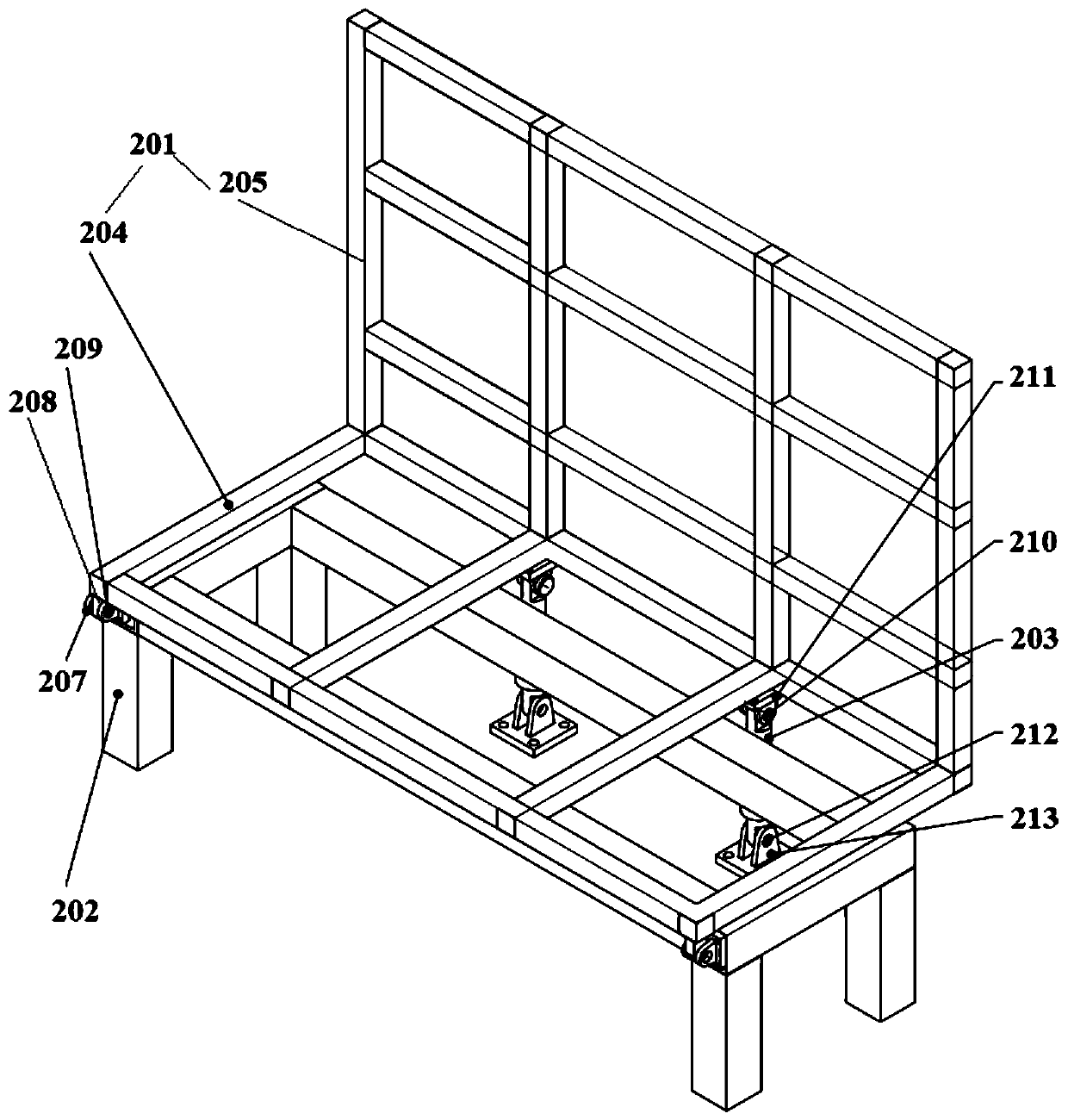

[0060] Drill rod case 2 comprises hopper 201, is located at the drill rod support 202 of hopper 201 below and tilts oil cylinder 203; Inside the hopper 201 and parallel to the bottom frame 204 and the side frame 205; the two sides of the bottom frame 204 are the hinged side and the jacking side respectively, the hinged side is hinged with the drill pipe support 202 below it, and the upper end of the jacking side is a side frame 205, which can be lifted The bottom of the side...

Embodiment 2

[0088] This embodiment provides a control method for an automatic feeding system for drill pipe processing, including the following steps:

[0089] Step 1, unloading: hoist the entire drill pipe into the drill pipe box manually, and the height of the drill pipe should not exceed the buffer device;

[0090] Step 2, the action of the one-level step material distribution unit: when the buffer device sensor detects that there is no drill pipe on the buffer device, and the first-level step sensor detects that there is a drill pipe, the material distribution jacking cylinder that controls the first-level step material distribution unit starts the first step. For one jacking action, stay at the highest point for 2 seconds to ensure that the drill pipe rolls down to the buffer device due to gravity along the slope of the first step material distribution unit, and the first step material distribution unit falls, and this process is completed once. A single drill pipe works separately f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com