Full-automatic paint pool device for sand core dip-coating

A fully automatic and automatic feeding technology, applied in the field of sand casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

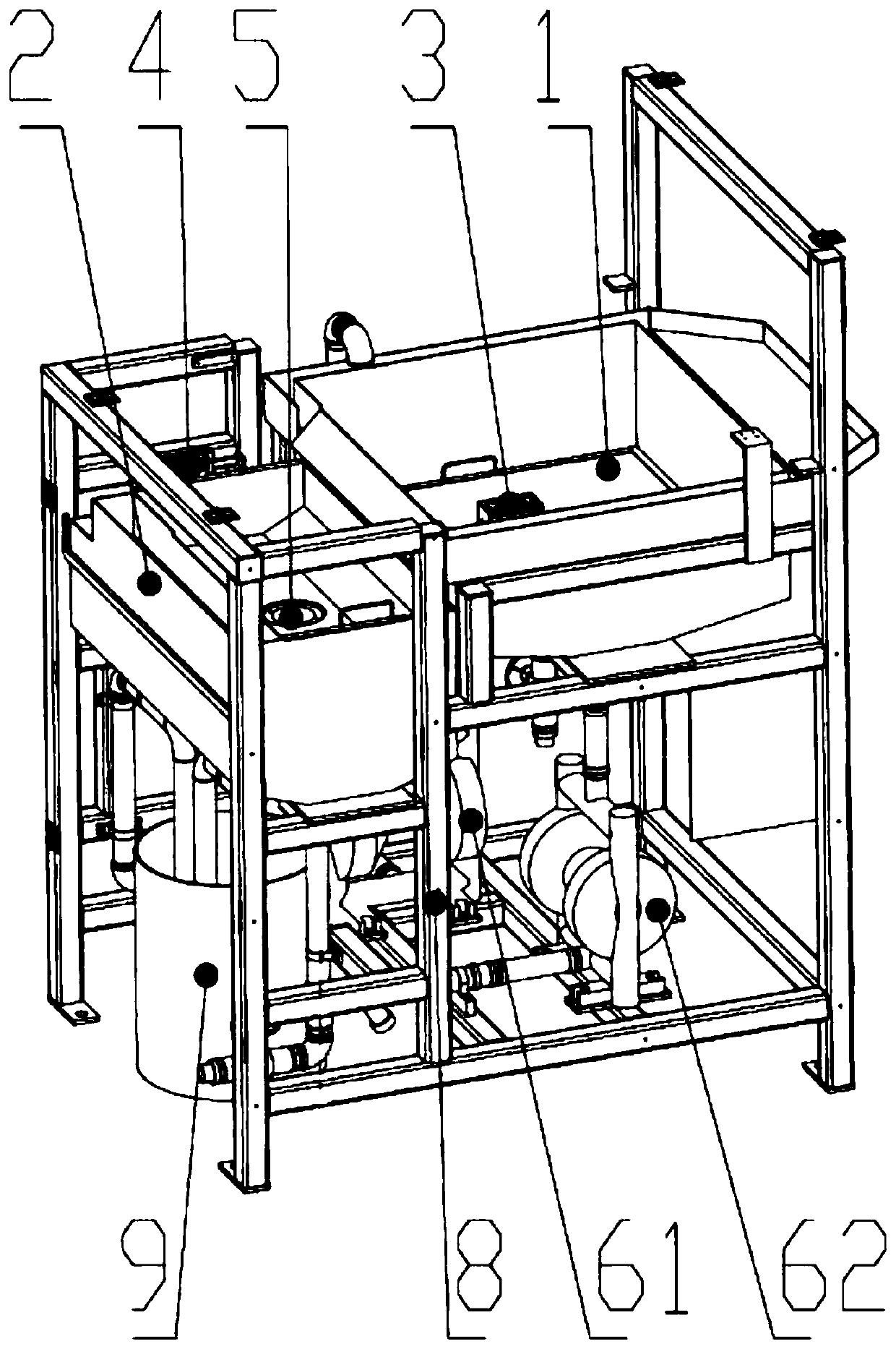

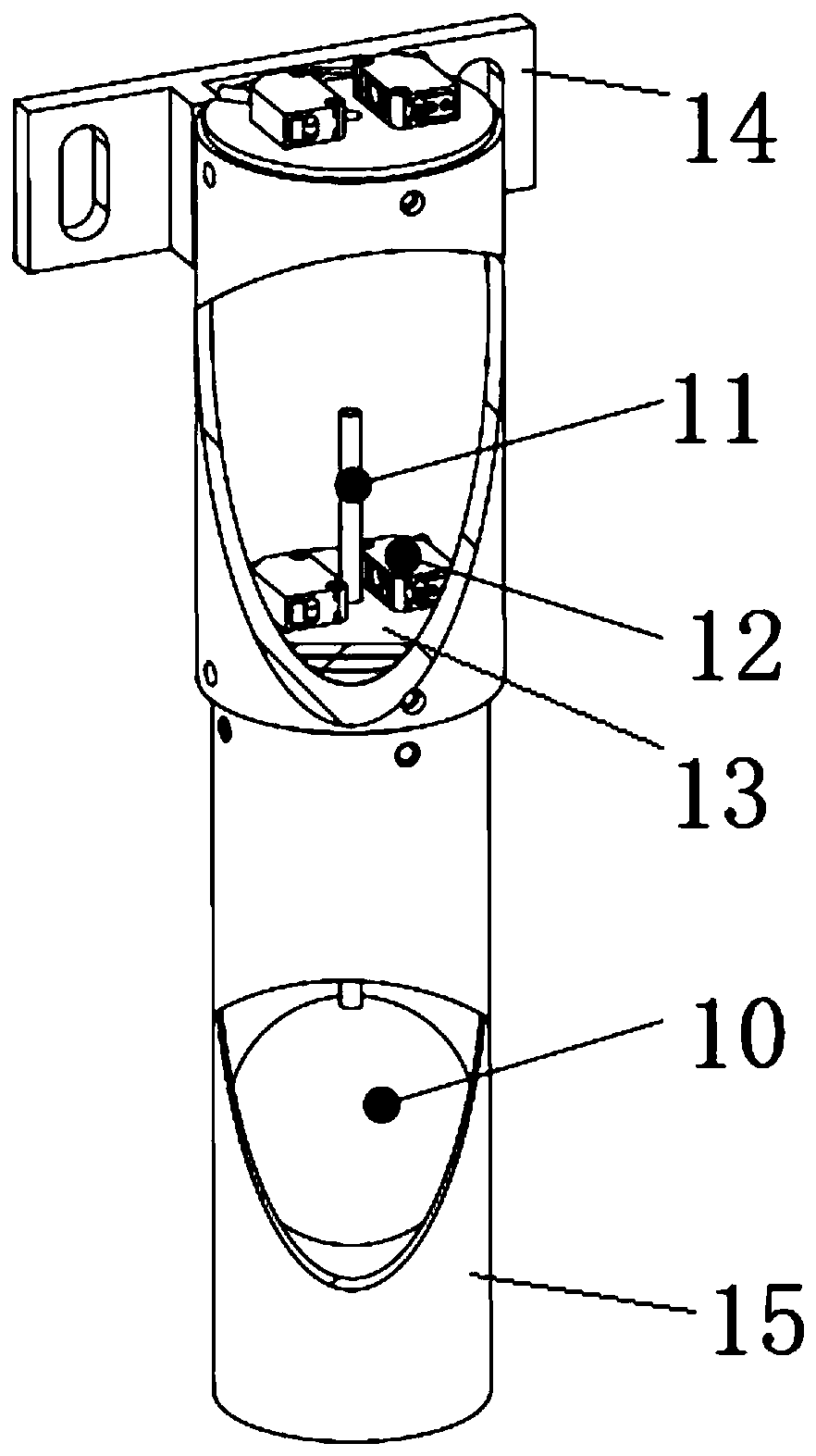

[0012] combine figure 1 , a kind of sand core dip-coating of the present invention is used full-automatic coating pool device, comprises a set of coating automatic feeding pipeline system, a set of coating circulating flow pipeline system, a set of dip coating pool 1 with constant liquid level, a set of Set of paint filter pool 2, two sets of liquid level detection devices, support frame 8, paint bucket 9;

[0013] The dipping pool 1 and the paint filter pool 2 are all fixed on the support frame 8; the dipping pool 1 and the paint filter pool 2 are equipped with a liquid level detection device, which is used to detect the liquid level in the two pools respectively. Height: the paint automatic feeding pipeline system connects the paint bucket 9 and the paint dipping pool 1, when the liquid level detection device in the paint filter pool 2 dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com