Automatic feeding and discharging device

A technology of automatic loading and unloading and material blocking, which is applied in metal processing and other directions, and can solve the problems of workers' occupational injuries, loud noises, and fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

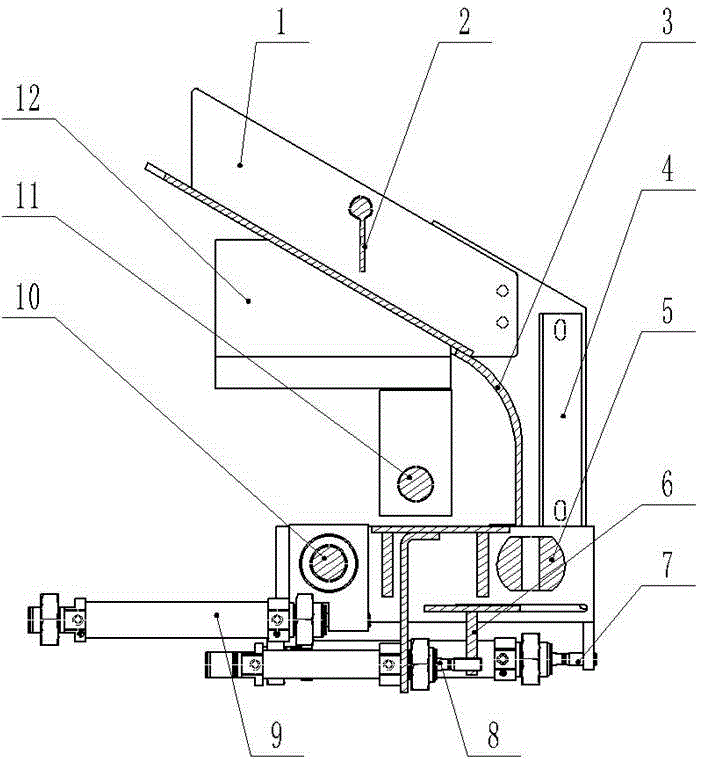

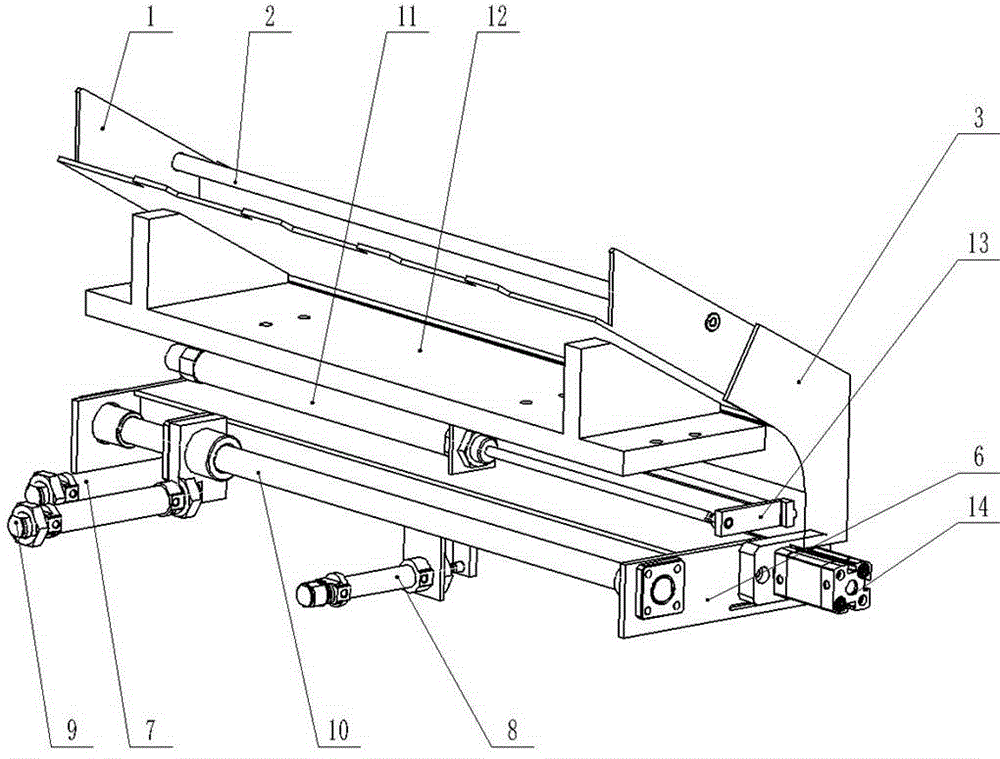

[0014] figure 1 It is a schematic structural view of an embodiment of the automatic loading and unloading device of the present invention, figure 2 It is a three-dimensional structural schematic diagram of an embodiment of the automatic loading and unloading device of the present invention, in figure 1 , 2 Among them, the automatic loading and unloading device of the present invention includes:

[0015] Sliding plate 1, buffer frame 2, steering groove 3, thickness adjustment plate 4, fixture 5, translation support 6, turning cylinder 7, unloading cylinder 8, feeding cylinder 9, horizontal slide rod 10, length centering cylinder 11, support Seat 12, centering block 13, clamping cylinder 14;

[0016] The connection relationship is that the support 12 is connected to the front-end screening material mechanism and installed on the frame; the slide plate 1 is installed above the support 12, and the opening at the top position is connected with the front-end screening material m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com