T-shaped interface supply device for non-polyvinyl chloride (PVC) soft bag large transfusion production line

A supply device and large infusion technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., to achieve continuous operation, reduce cylinder impact, and solve the problem of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

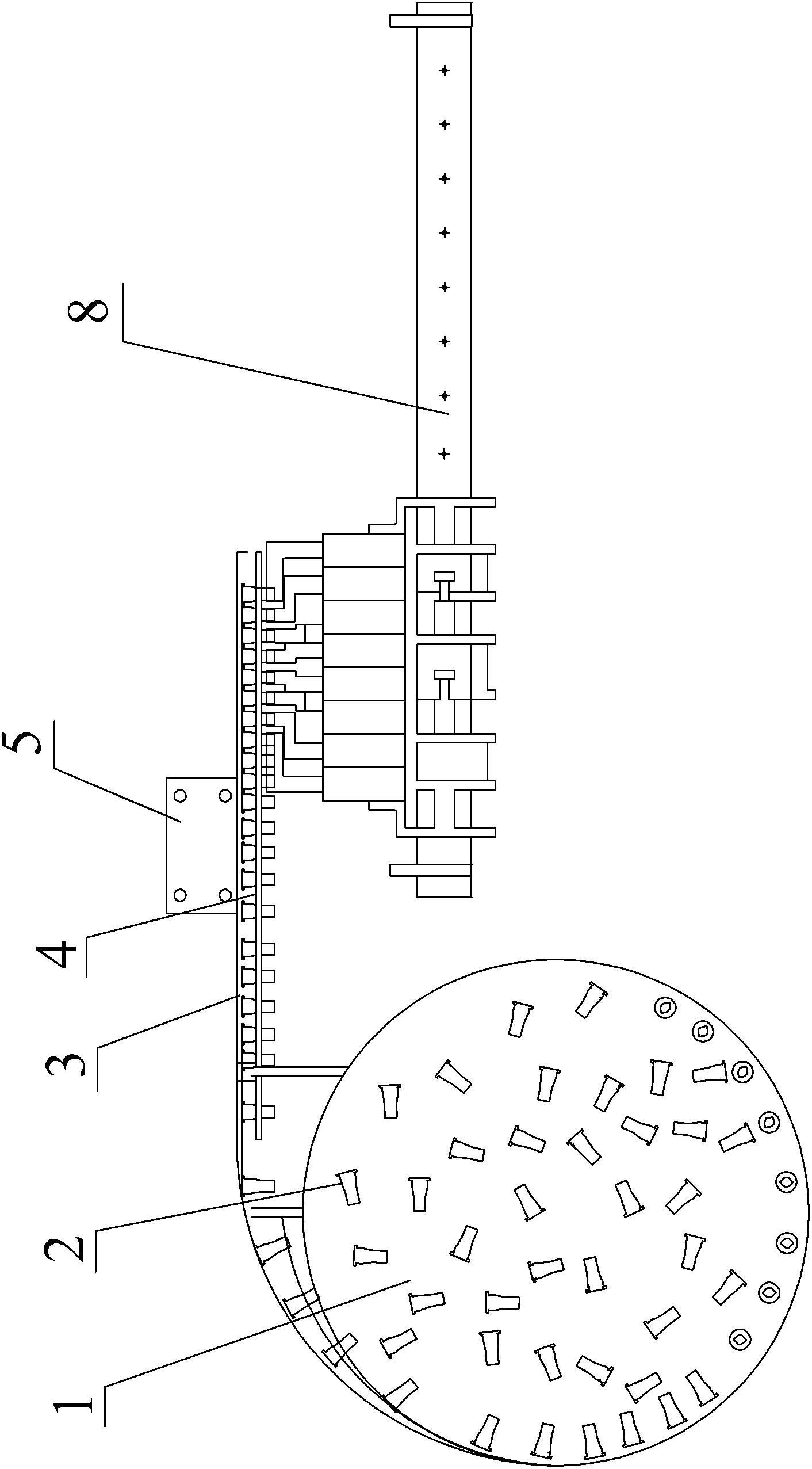

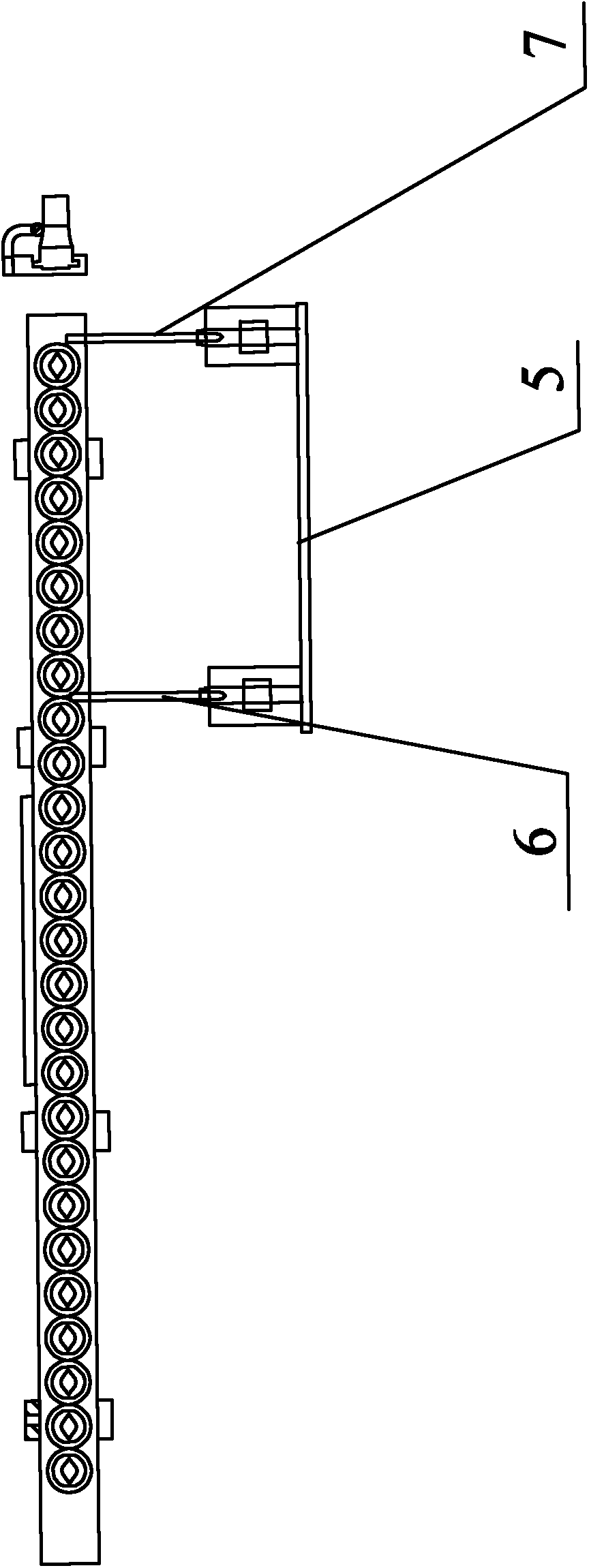

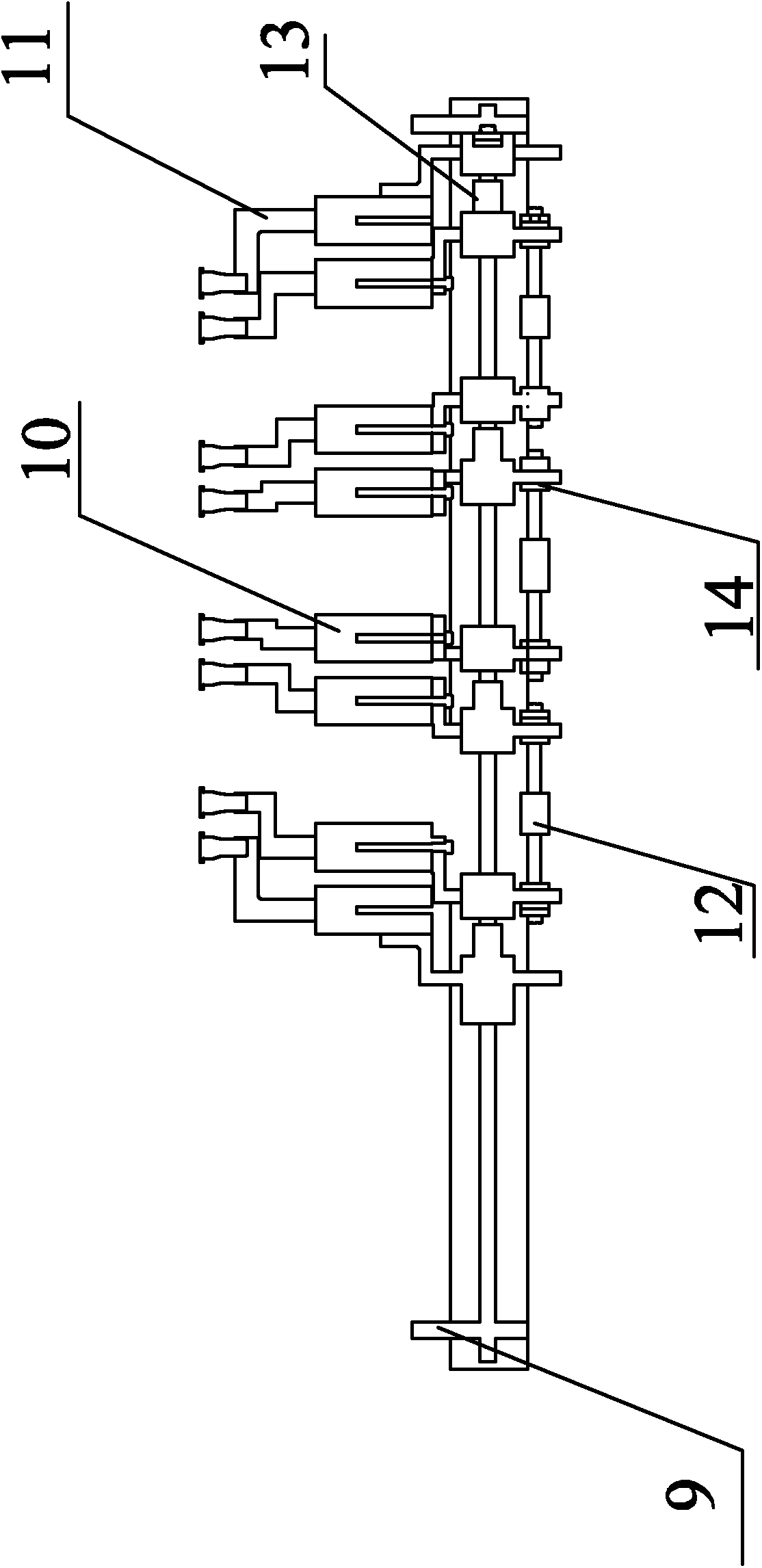

[0024] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a T-shaped interface supply device for a non-PVC soft bag large infusion production line, including a vibrating hopper 1, a linear slideway 3 and a horizontal bracket 4, and a horizontal bracket 4 is arranged in parallel below the linear slideway 3, and a straight line The slideway 3 is located obliquely above the vibrating hopper 1, and a clamping device is installed below the linear slideway 3, and a linear guide rail 8 is provided at the bottom of the clamping device. Limiting frames 9 are provided at both ends of the linear guide rail 8, and grippers are provided on the linear guide rail 8. 10. The upper end of each gripper 10 is provided with parallel air claws 11 .

[0025] The present invention adopts a brand-new form in which the interfaces are transported side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com