Automatic timed and quantitative feeding device for interval cages

An automatic timing, cage technology, applied in animal feeding devices, poultry industry, applications, etc., can solve problems such as multiple cages, and achieve the effect of accurate feeding and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific content and working process of the present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

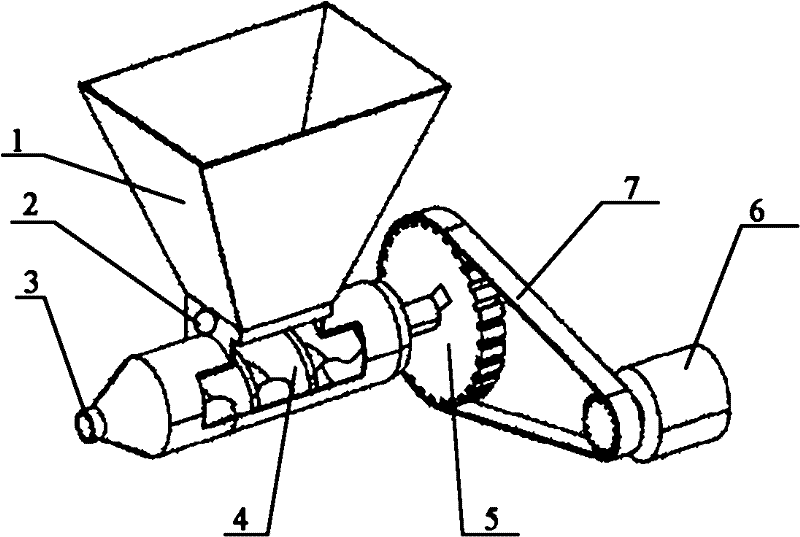

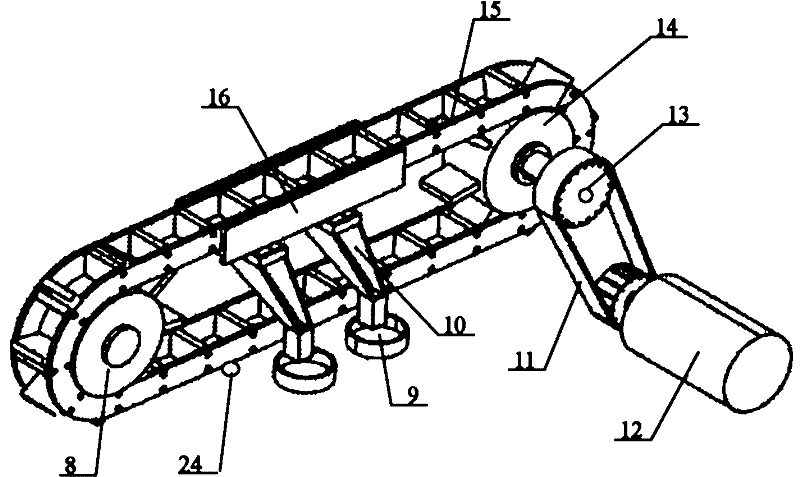

[0025] The invention mainly includes a feed distribution system, a feed delivery system and a control system. The feed distribution system is mainly to transport the stored feed to the feed delivery system at a uniform speed, and the feed delivery system delivers the feed to each cage respectively. The function of the control system is to control the completion of these actions and realize the compartmental multiple cages. Automatic timing and quantitative feeding.

[0026] 1. Feed distribution system

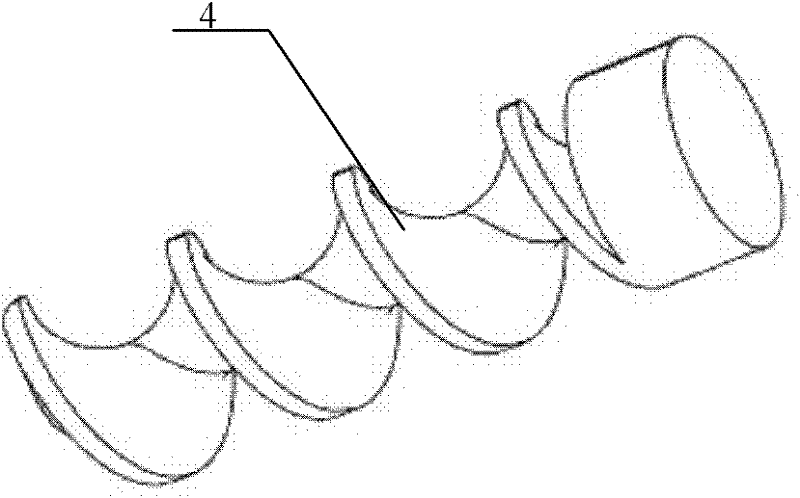

[0027] The feed distribution system consists of a storage hopper 1, a screw batching mechanism 4, a pulley 5, a belt 7 and a stepping motor 6, see figure 1 shown. In order to make the drawing clear, the lower part of the shell of the storage hopper 1 is removed during drawing, so that the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com