Automatic feeding device for knitter and control method

An automatic feeding and knitting machine technology, which is applied in the direction of braided fabrics, textiles, and papermaking, can solve the problems of wasting braiding threads, time-consuming and laborious, long braids in braided tubes, etc., and achieve the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

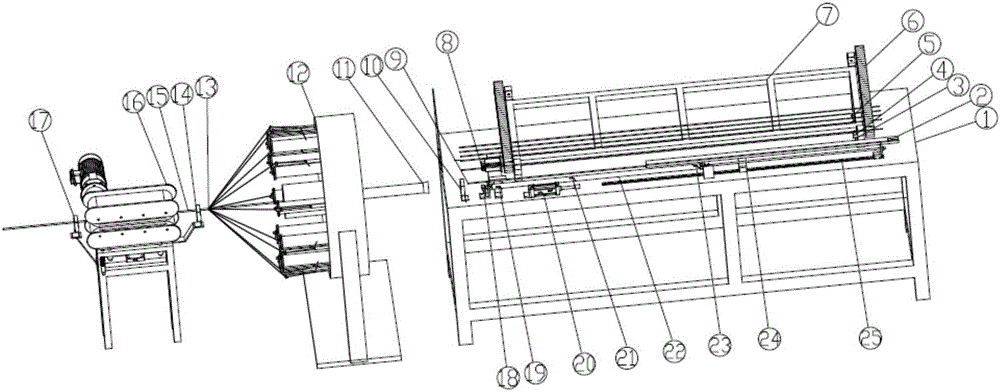

[0018] like figure 1 As shown, an automatic feeding device for a knitting machine includes a base 1, a blanking trough 2, an adjustment bracket 3, a steel core detection sensor 4, a material shortage detection sensor 5, a pulley 6, a bracket 7, a blanking motor 8, Steel core with rubber 9, first annular steel core sensor 110, guide cylinder 11, braiding machine 12, braiding point 13, second annular steel core sensor 14, braided tube 15, tractor 16, third annular steel core Sensor 17, steel core drop detection sensor 18, cylinder front position magnetic switch 19, buffer cylinder 20, braiding point magnetic switch 21, feeding cylinder 22, cylinder rear position magnetic switch 23, slide block 24, guide rail 25.

[0019] The blanking motor 8 of the automatic feeding device of the braiding machine drives the pulley 6 to turn over from top to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com