Automatic pulp feeding machine suitable for feeding pulp

A pulp and feeding technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of high risk, pollution, labor intensity of workers, etc., to eliminate manual operations, reduce labor costs, and achieve Fully automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

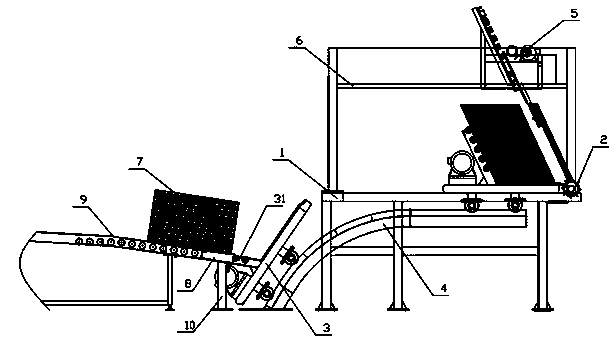

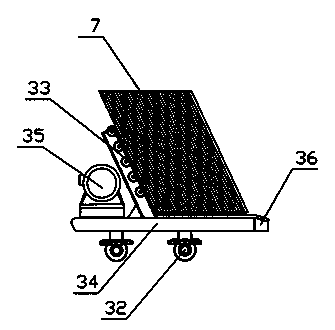

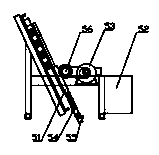

[0043] An automatic pulp feeding machine suitable for pulp feeding, comprising a frame 1, the frame 1 is provided with a feeding port formed by a paper stripping mechanism 2, and the frame 1 is also provided with a material receiving conveyor A material mechanism and a material pushing mechanism, the material receiving and transporting mechanism includes a material transporting trolley 3 and a material transporting track 4 for the transporting material trolley 3 to walk, the described transporting material trolley 3 is arranged on the material transporting track 4, and the transporting material A material receiving plate 31 is inclinedly arranged on the material trolley 3, and the material delivery track 4 includes an ascending section and a horizontal section, one end of the ascending section is connected to the pulp end, and the other end of the ascending section is connected with an end of the horizontal section, so The other end of the horizontal section is the pulp-inverti...

Embodiment 2

[0057] An automatic pulp feeding machine suitable for pulp feeding, comprising a frame 1, the frame 1 is provided with a feeding port formed by a paper stripping mechanism 2, and the frame 1 is also provided with a material receiving conveyor A material mechanism and a material pushing mechanism, the material receiving and transporting mechanism includes a material transporting trolley 3 and a material transporting track 4 for the transporting material trolley 3 to walk, the described transporting material trolley 3 is arranged on the material transporting track 4, and the transporting material A material receiving plate 31 is inclinedly arranged on the material trolley 3, and the material delivery track 4 includes an ascending section and a horizontal section, one end of the ascending section is connected to the pulp end, and the other end of the ascending section is connected with an end of the horizontal section, so The other end of the horizontal section is the pulp-inverti...

Embodiment 3

[0076] The difference from Embodiments 1 and 2 is that: the transmission member is a transmission gear, and the inclination angle of the receiving plate 31 is 90 degrees.

[0077] The technological process of an automatic pulp feeder suitable for pulp feeding is as follows:

[0078] Material receiving: the front end conveying belt 9 and the material transport trolley 3 carry out the handover of pulp and paper piles;

[0079] Feeding: the feeding trolley 3 sends the pile of pulp paper along the feeding track 4 to the feeding port, and on the way on the feeding track 4, the material is turned over by changing the angle of the arc-shaped rising section;

[0080] Pushing material: The pushing mechanism operates after receiving the signal of incoming material to push the pile of pulp and paper at a uniform speed;

[0081] Feeding: The paper stripping mechanism conducts paper stripping and feeding in an orderly manner;

[0082] Circulation: The above technological process runs cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com