Device for producing components of filter screen

A production device and filter technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve problems such as backward production methods, unguaranteed product quality, and low efficiency, so as to improve product quality and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

[0023] It should be noted that: in this document, the first mold 100 and the first mold 100 are relative concepts, the first mold 100 can be a fixed mold or a moving mold, and the corresponding second mold 200 can be a moving mold or a fixed mold .

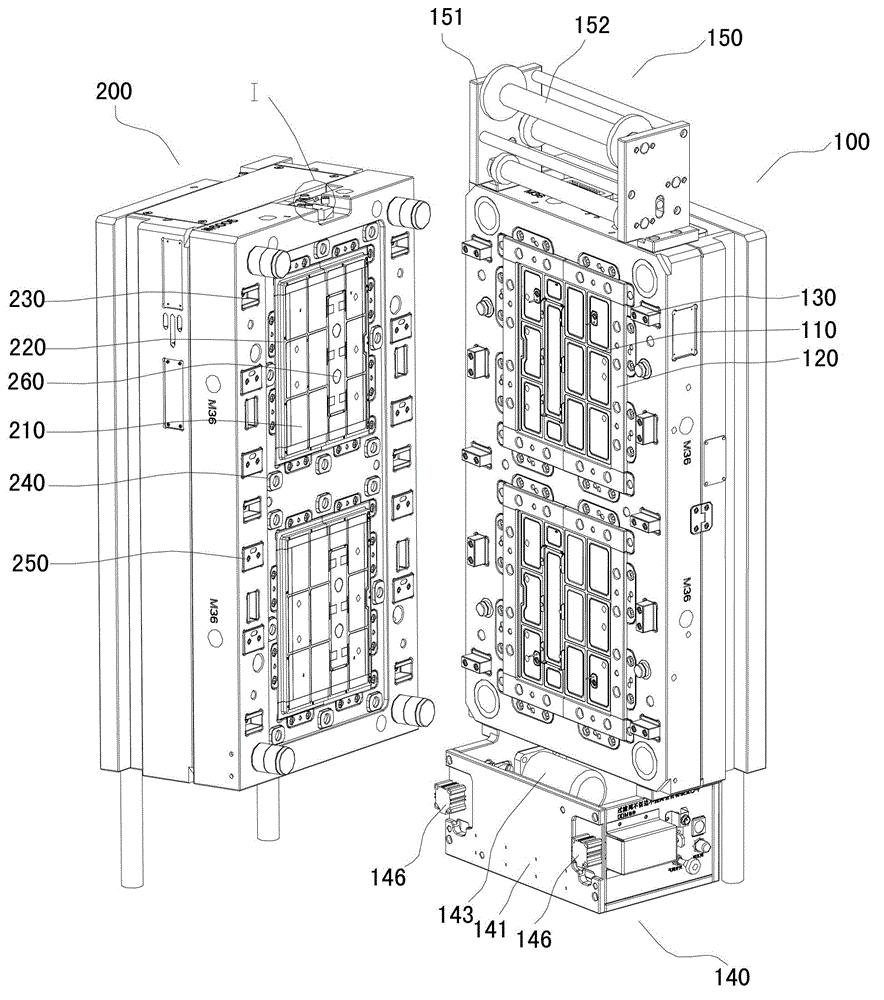

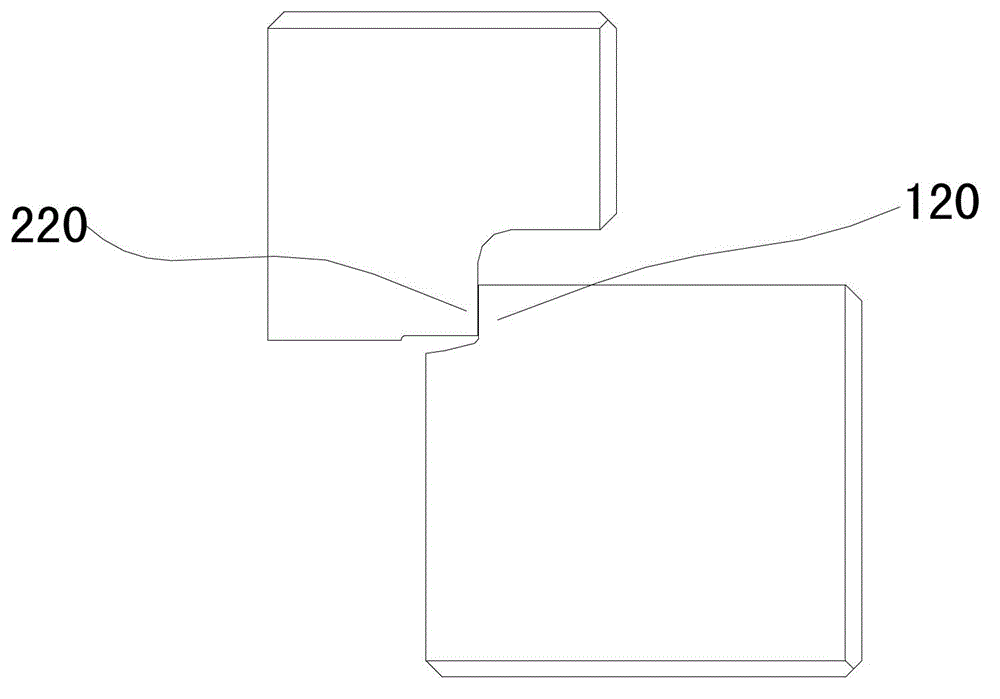

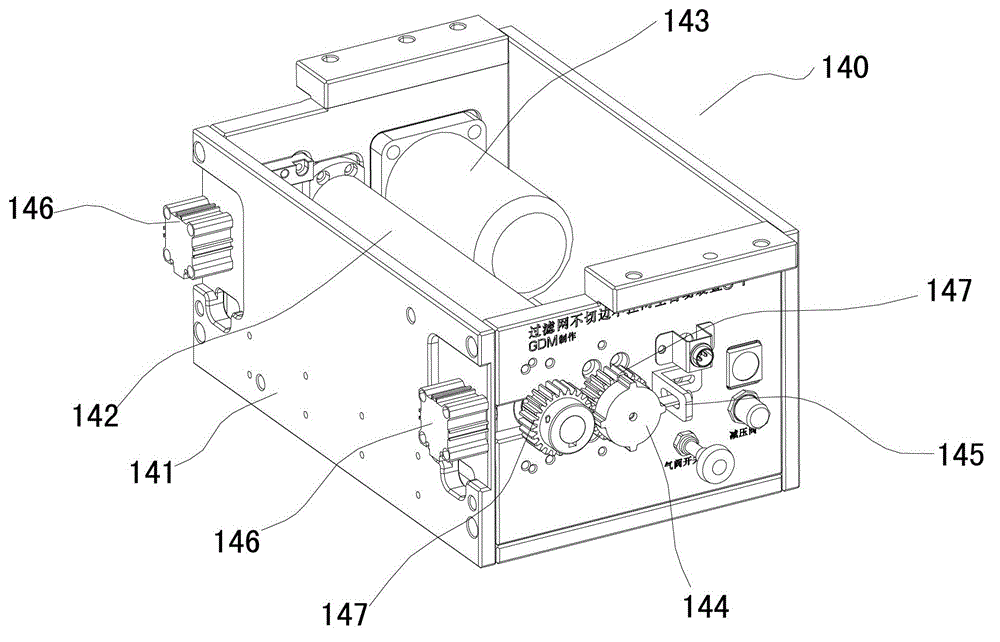

[0024] See figure 1 , figure 1 Shown is a schematic diagram of the structure of the filter assembly production device in one of the embodiments of the present invention, the filter assembly production device includes a first mold 100 and a second mold 200, the left side of the first mold 100 forms a first parting Surface 110, the right side of the second mold 200 forms the second parting surface 210; when the molds are closed, the first parting surface 110 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com