Full-automatic laminated glass production system and process thereof

A technology of laminated glass and production system, applied in the field of fully automatic laminated glass production system, can solve the problems of increased factory investment cost, low production efficiency, large floor space, etc., to improve production efficiency, safety performance, and processing accuracy Improved and reduced footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

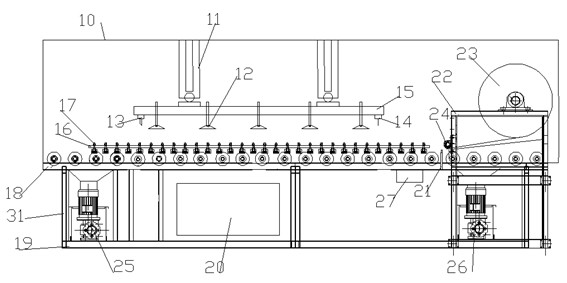

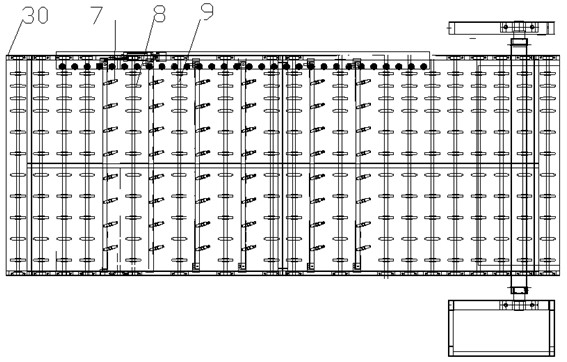

[0019] The fully automatic laminated glass production system includes loading table 1, cleaning machine 2, air dryer 3, positioning film laying and laminating table 4, rolling machine 5 and unloading table 6, and positioning film laminating and laminating table 4 includes oblique transmission Wheel 7, horizontal transmission wheel 8, transmission shaft 9, suction cup frame 10, cylinder 11, vacuum suction cup 12, transverse film cutting mechanism 13, longitudinal film cutting mechanism 14, suction cup plate 15, positioning plate 16, positioning pulley 17, positioning platform 18 , base 19, integrated air purification device 20, film clamp 21, film frame 22, film spreader 23, glue outlet 24, first motor 25, second motor 26, third motor 27, first Guide rail 28, second guide rail 29, third guide rail 30, support 31; loading table 1, washing machine 2, air dryer 3, positioning film laying and laminating table 4, rolling machine 5, unloading table 6 are connected in sequence; The ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com