Mixing delivery over-flow valve double seal assistant

An overflow valve and double-seal technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of equipment vibration, failure to guarantee valve sealing, stability, safety, etc., achieve high safety and improve production Efficiency and safety performance, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

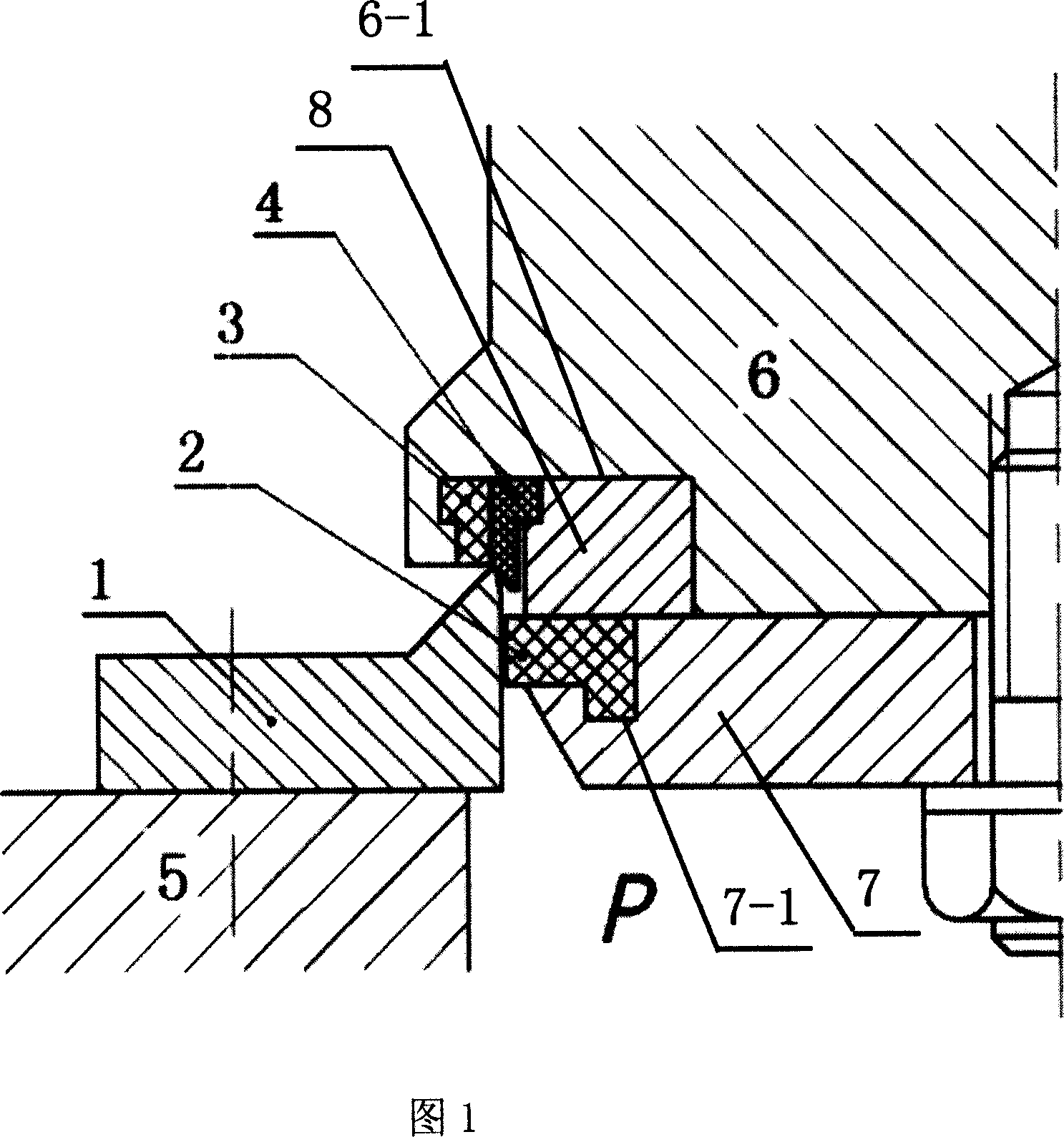

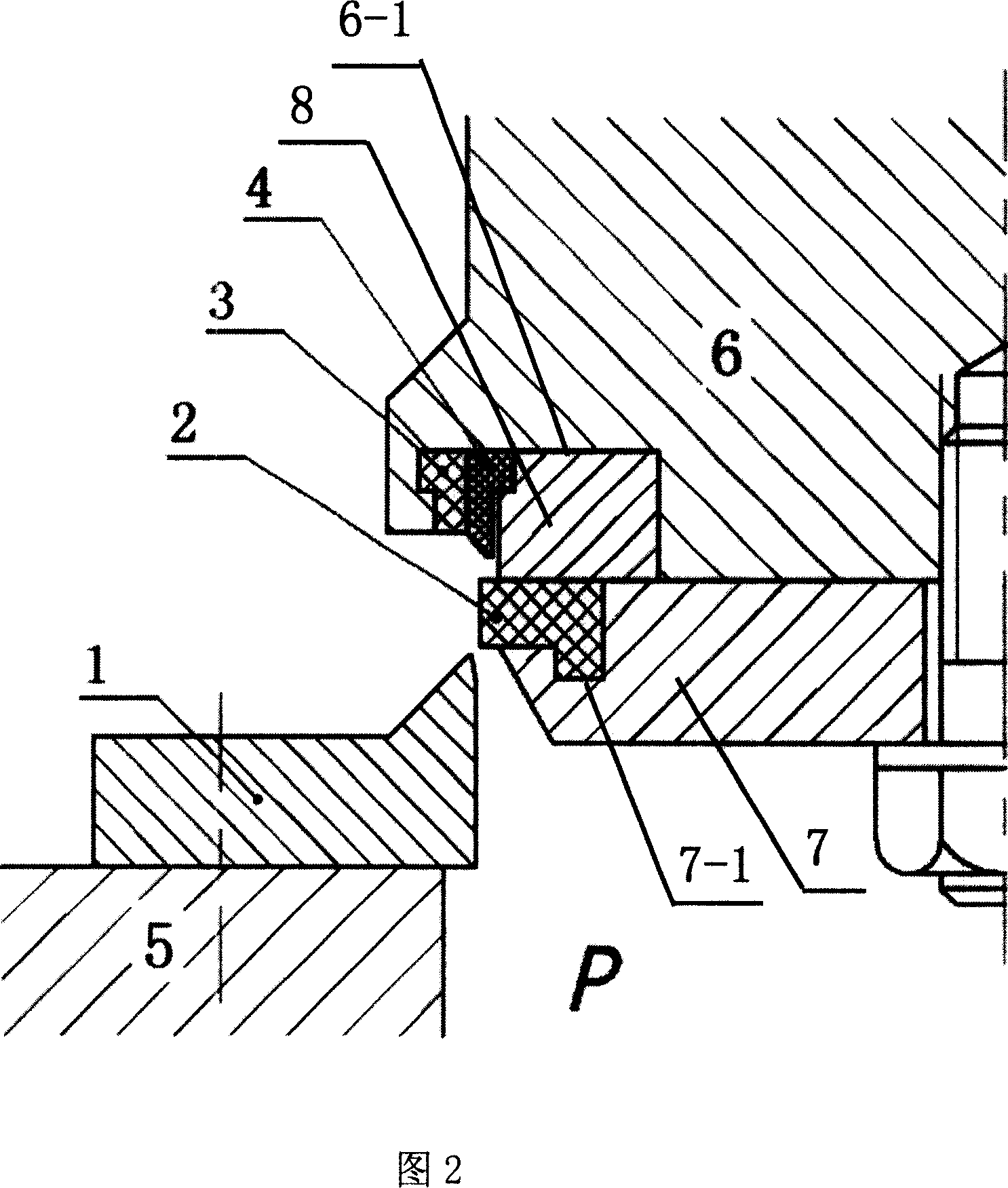

[0016] As shown in Figures 1 and 2, the double sealing pair of the mixed transmission relief valve includes an upper sealing pair and a lower sealing pair 1, the upper sealing pair is arranged at the lower end of the valve core, and the lower sealing pair 1 is fixedly installed on the valve body 5 The upper and lower sealing pairs 1 are provided with a flange along the upper end of the inner circumference, and its cross-section is knife-edge shaped. The upper sealing pair includes a sealing ring 2, a ferrule 3, and a sealing ring 4. The sealing ring 2 is fixed under the valve core 6 through a fixing block 7. On the end face, the sealing ring 2 is embedded in the upper ring groove 7-1 of the fixed block 7; the sealing ring 4 is embedded in the lower ring groove 6-1 of the lower end surface of the valve core 6 through the ferrule 3 and the fixed ring 8, and the ferrule 3 is located on the outer circumference of the sealing ring 4, and the fixed ring 8 is located on the inner circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com