Unmanned kitchen

A kitchen and vegetable cleaning box technology, applied in kitchen utensils, packaging, cooking utensils, etc., can solve the problems of physical hazards for eaters, low degree of automation, and easy hygiene problems, etc., to achieve easy control of seasoning dosage, fast and intelligent control, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

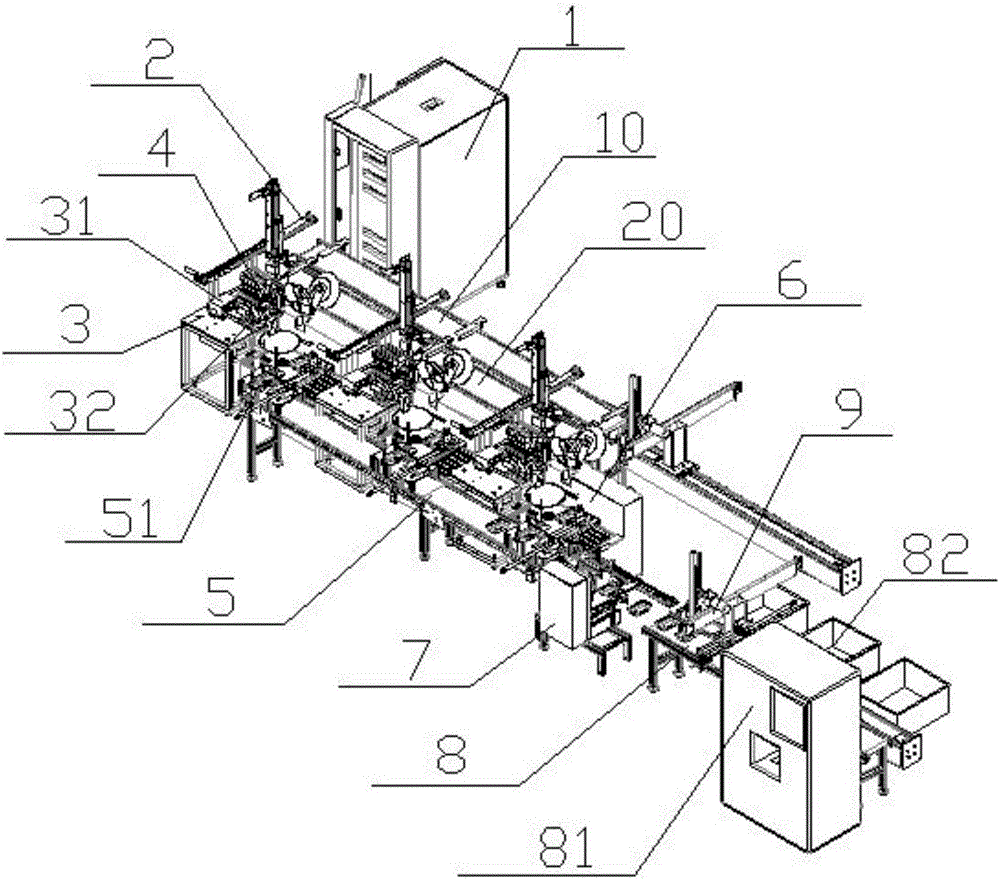

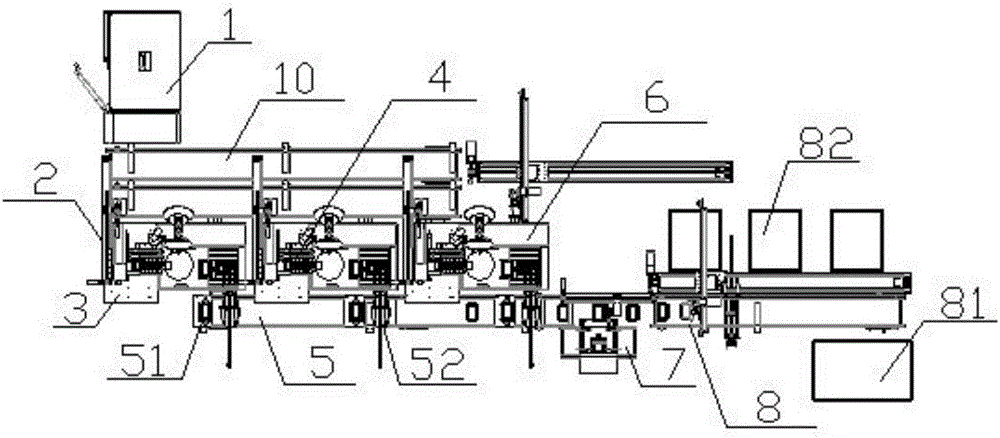

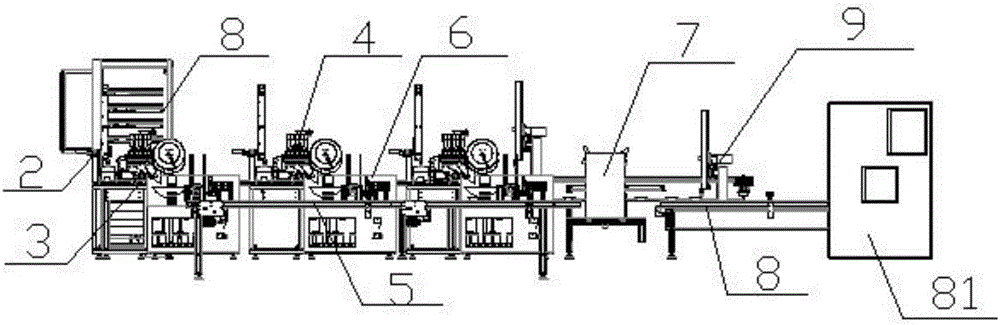

[0028] refer to Figure 1 to Figure 9, an unmanned kitchen of the present invention, comprising a vegetable cleaning cabinet 1, a vegetable cleaning box conveying device 2, a placing rack 3, a seasoning feeding device 4, a first conveying platform 5, a cooking machine 6, a second conveying platform 8, and a meal box sorting device 9. The vegetable cleaning cabinet 1 is integrally connected by the main cabinet and the auxiliary cabinet 12 with a sliding door. The vegetable cleaning cabinet 1 is provided with a display 15, a plurality of speakers 11, a meal opening 14 and a glass door 16. The vegetable cleaning cabinet 1 is equipped with There are lunch box lifting platform and if clean vegetable box access frame 13, one side of clean vegetable cabinet 1 is provided with clean vegetable box conveyer belt 10, and the adjacent position of clean vegetable box conveyer belt 10 is provided with empty box conveyer belt 20, empty box conveyer belt 20 One side of the same number is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com