Wire harness seal sleeve demolding manipulator and production equipment with same

A technology of sealing sleeve and manipulator, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of difficult disassembly, high labor cost, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

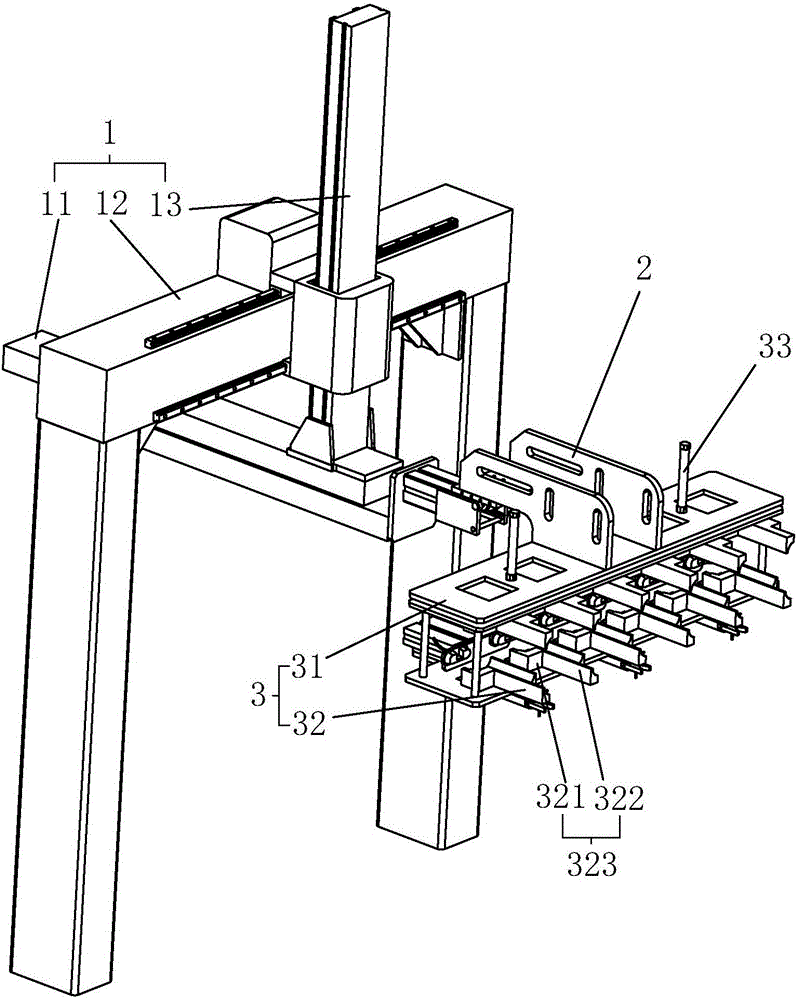

[0039] Example one, as Figure 1-2 As shown, a wire harness sealing sleeve demoulding robot includes a triaxial displacement table 1, a clamping assembly 3 for clamping the wire harness sealing sleeve, and a connecting arm 2 for connecting the triaxial displacement table 1 and the clamping assembly 3, The three-axis displacement stage 1 is a common equipment on the market, which usually includes an X beam axis 12, a Y beam axis 13 and a Z beam axis 11, which are mainly used to realize the displacement of three degrees of freedom, front and rear, up and down, and left and right, One end of the connecting arm 2 is connected to the Z beam shaft 11 and the other end is connected to the clamping assembly 3 .

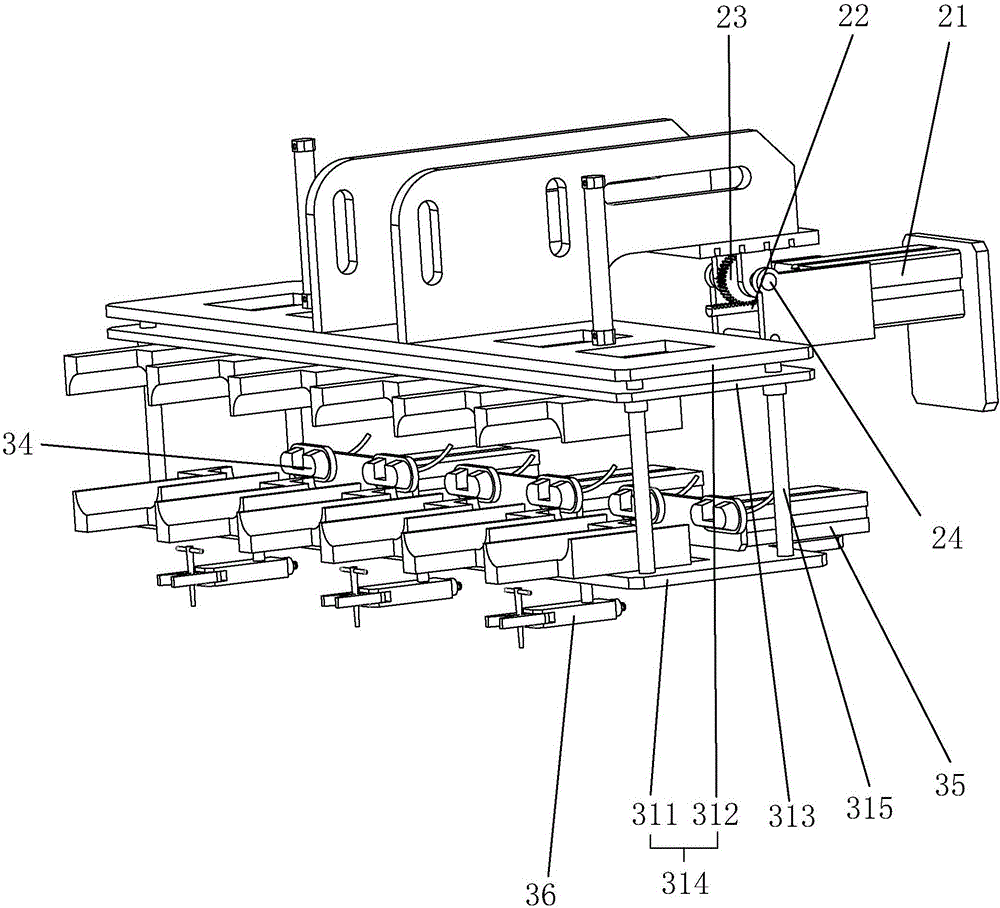

[0040] The clamping assembly 3 includes a bracket 31 and a demolding member 32 fixed on the bracket 31. The bracket 31 includes a fixing plate 314 and a sliding plate 313. The fixing plate 314 further includes a top plate 311 and a bottom plate 312. The plate 313 is located ...

Embodiment 2

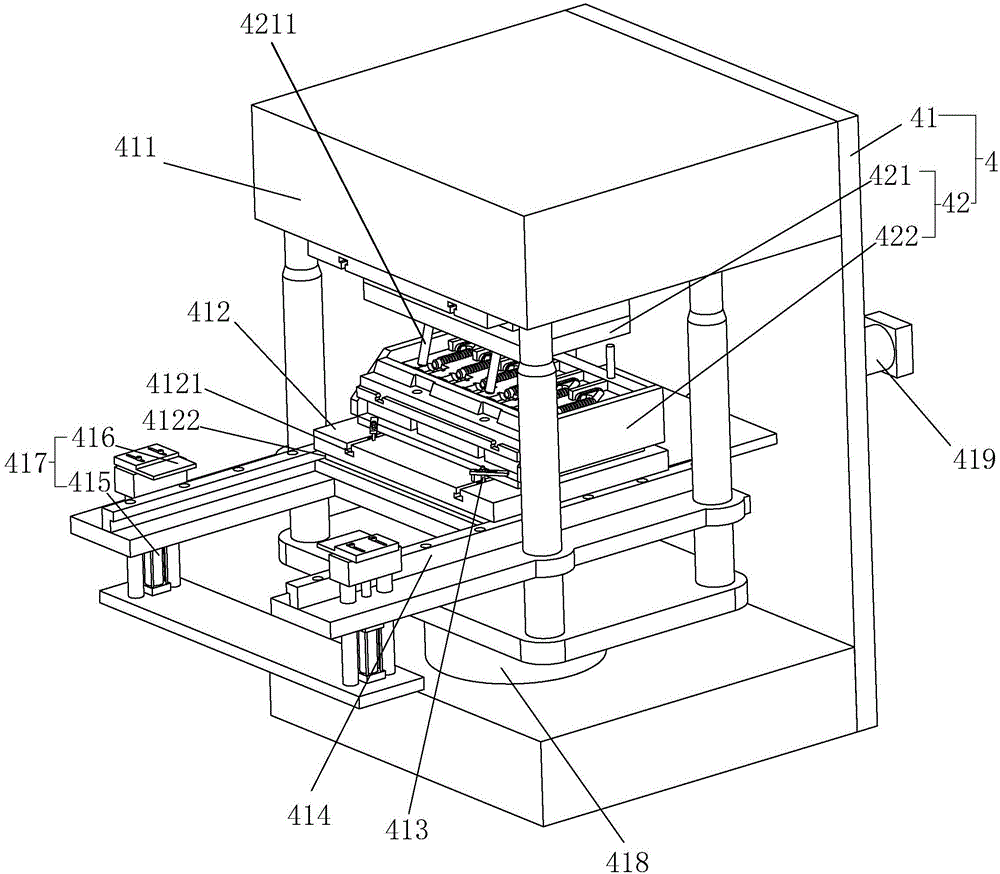

[0043] Example two, as Figure 3-Figure 4 As shown, a production equipment includes the wire harness sealing sleeve demoulding manipulator and the injection molding system 4 described in the first embodiment, the clamping component 3 of the wire harness sealing sleeve demolding manipulator is disposed toward the injection molding system 4, and the injection molding system 4 includes There is a frame 41, an injection mold 42 and an injection head for injecting the injection mold 42. The injection mold 42 includes an upper mold 421 and a lower mold 422, and the upper mold 421 and the lower mold 422 are both configured as concave molds. The mold cavity 53 is formed when the upper mold 421 and the lower mold 422 are closed, and the injection mold 42 is provided with the same number of mold cavities 53 as the number of the demolding parts 32, a total of six, and every two mold cavities 53 are a group, two The cavities 53 are communicated with each other by setting a flow channel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com