Full-automatic vertical mold-transferring hose injection head machine

A fully automatic, head injection machine technology, applied in the field of machinery, can solve the problems of failure to realize fully automatic operation, lifelong disability of the operator, low production efficiency, etc., and achieve the effects of saving labor, compact and reliable structure, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The head injection process of the PE plastic bottle that the full-automatic vertical turning pattern hose injection machine of the present invention is used for, PE plastic bottle is semi-finished product (opening at both ends) when entering this full-automatic vertical turning pattern hose injection machine Hollow hose), the intermediate product (hose with tube head) is injection-molded in the fully automatic vertical rotary mode hose head injection machine, and then the subsequent processes are carried out, such as forming the bottom of the bottle, configuring the bottle cap and other processes.

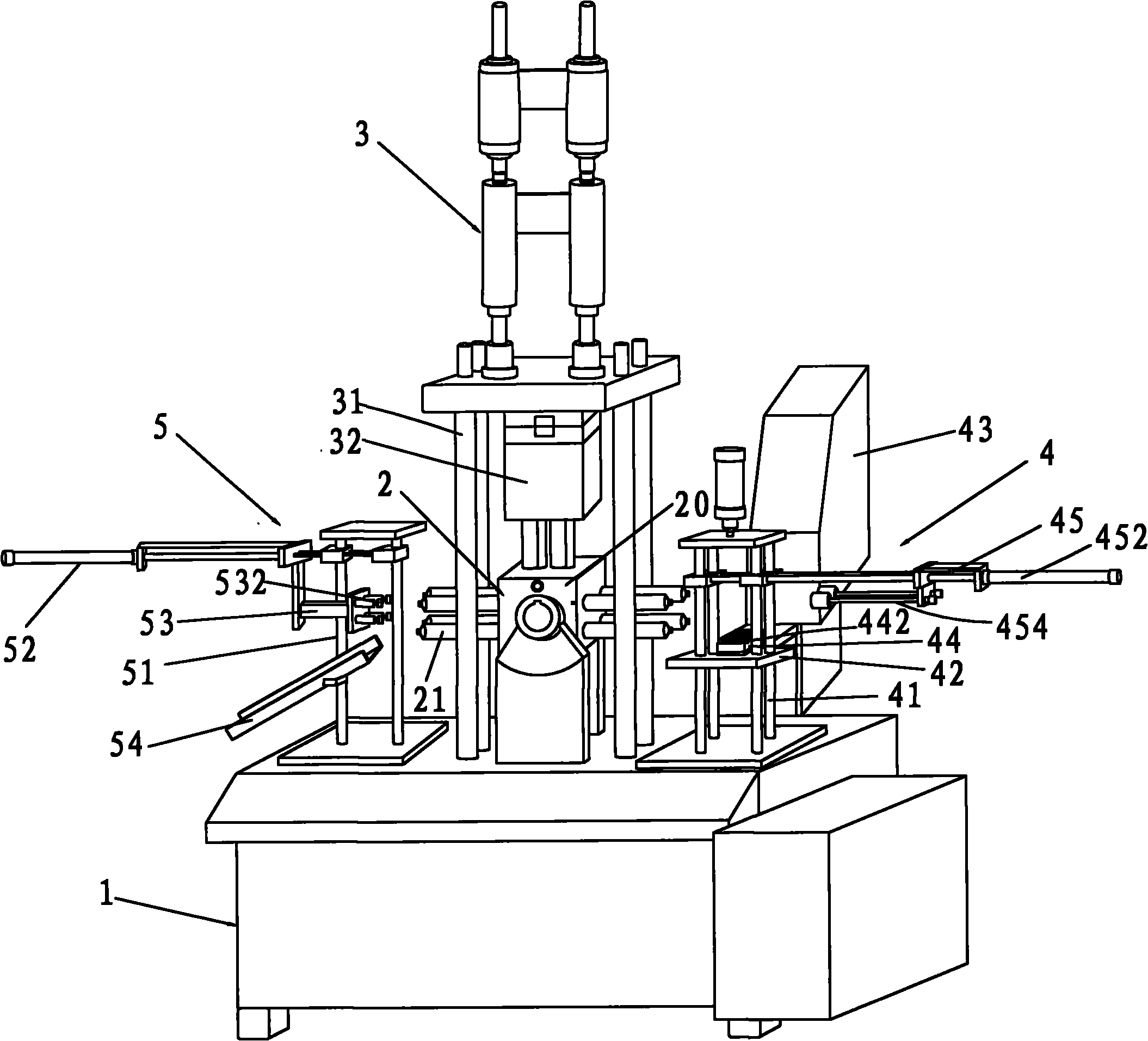

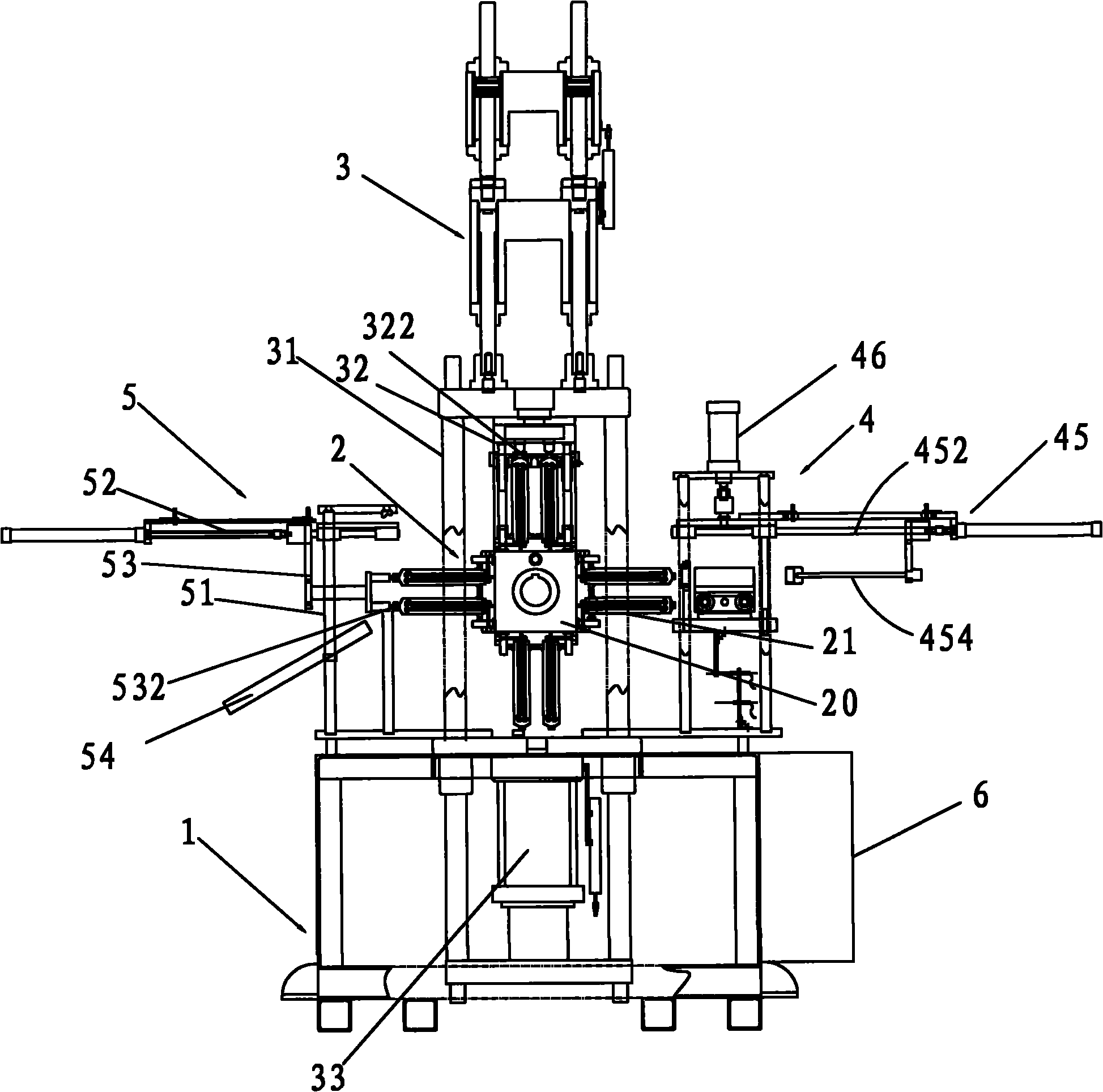

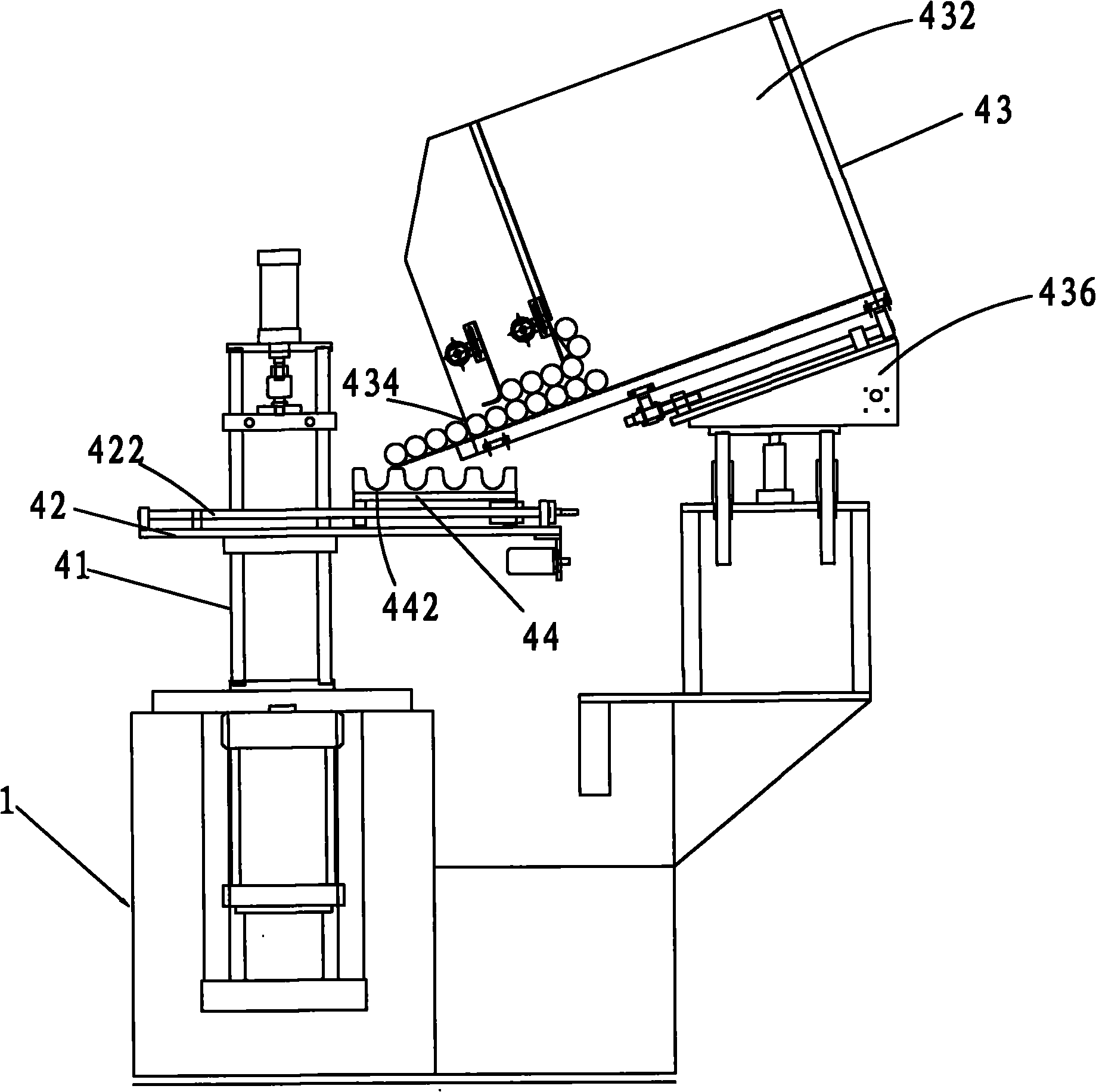

[0015] Such as Figure 1-2 As shown, the fully automatic vertical rotary mode hose injection machine of the present invention includes: a frame 1, a vertical rotary mold device 2 arranged on the frame 1, and an injection molding device 3 arranged above the rotary m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com