A making method for fully automated small ultra-thin chip inductor

An ultra-thin patch type, manufacturing method technology, applied in the direction of inductor/transformer/magnet manufacturing, inductors, fixed inductors, etc., can solve the problems of low production efficiency, product damage, copper wire coil damage, etc., to achieve production man-hours Less, more versatile, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

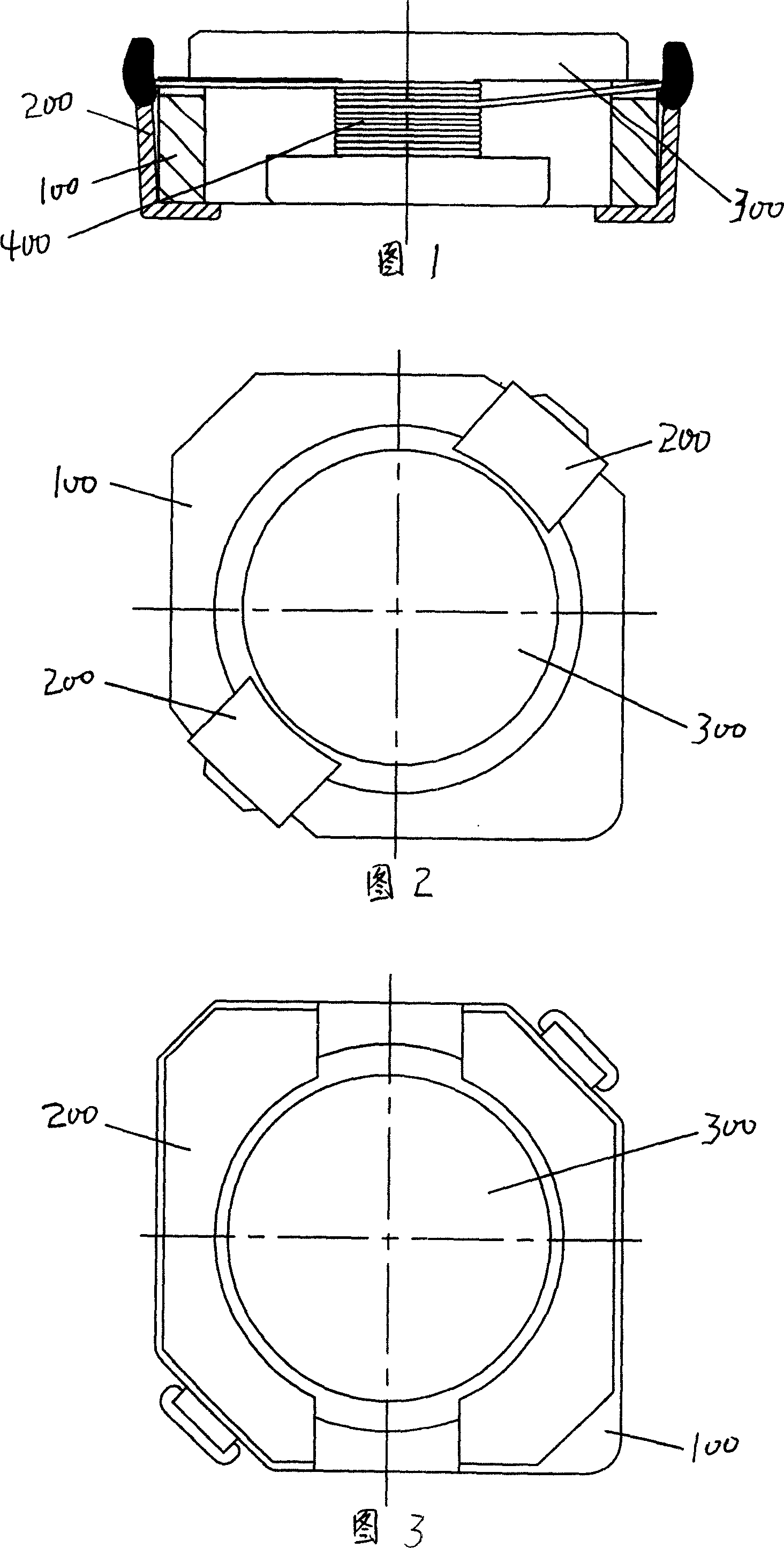

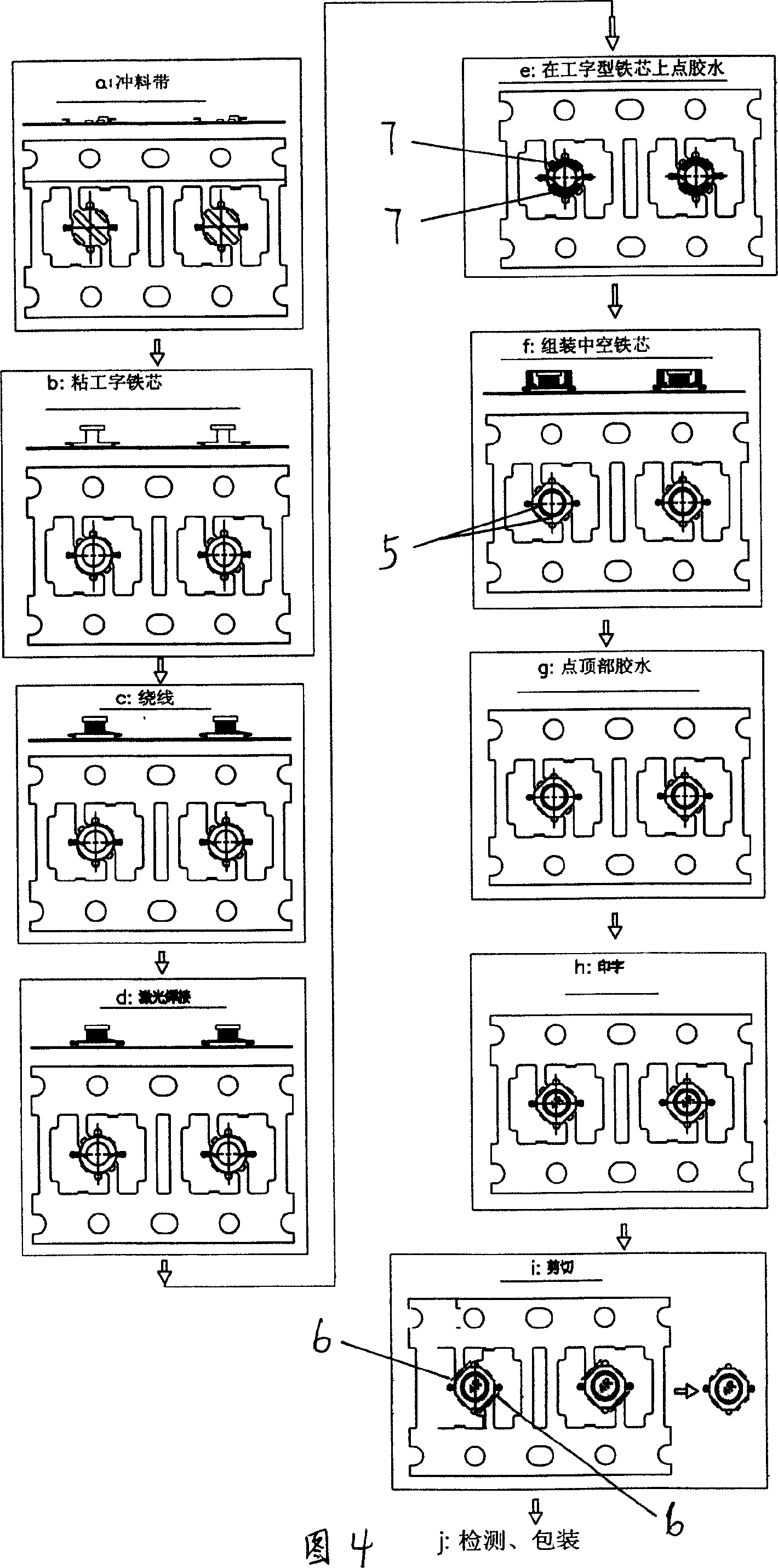

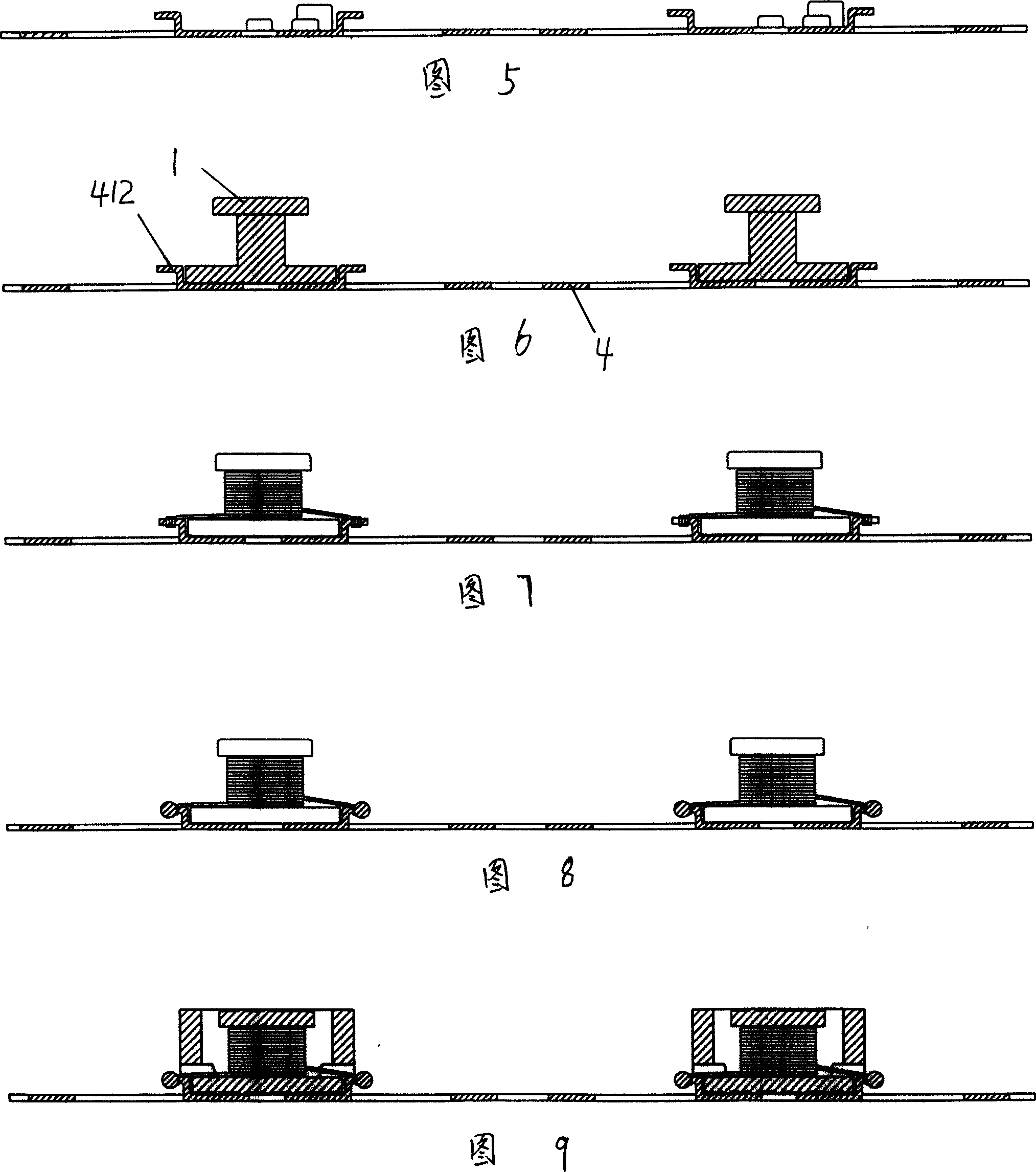

[0043] A kind of manufacture method of full-automatic small-sized ultra-thin patch type inductance, it is main raw material with I-shaped iron core 1, hollow iron core 2, copper coil 3, copper strip 4, and it comprises following process steps (as shown in Figure 4 shown):

[0044] a), punch a plurality of neatly arranged inductance bases 41 on the main body 4 of the copper strip, the base 41 is connected to the main body 4 of the strip through two 180-degree symmetrical connection sides 42, and there is a gap between the two connection sides 42 The inductance base 41 is divided into a separation hole 43 of two welding plates 411, the length of the separation hole 43 is slightly larger than the size of the hollow iron core 2; each welding plate 411 is respectively provided with an upwardly bent winding wire The terminal 412 and the small boss 413 protruding outwards are also punched with a positioning hole 44 for pulling to the main body of the material strip for the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com