Novel full-automatic numerical control board packaging machine

A fully automatic, wrapping machine technology, used in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc. Problems such as low efficiency, to achieve the effect of improving the efficiency of the package board, accurate alignment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

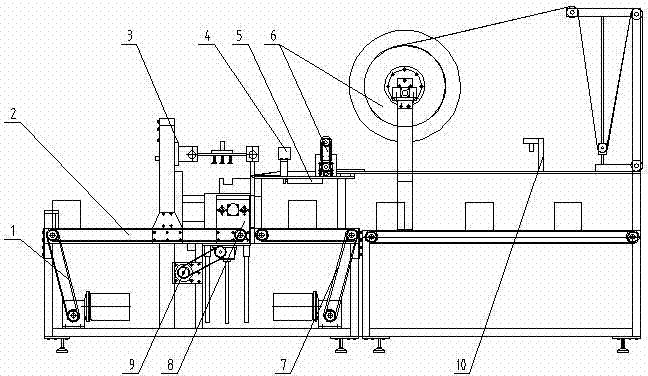

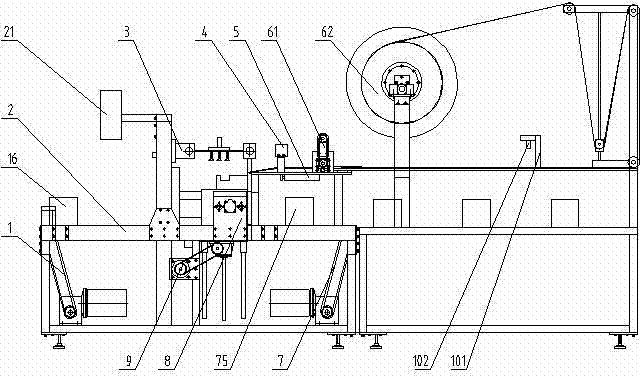

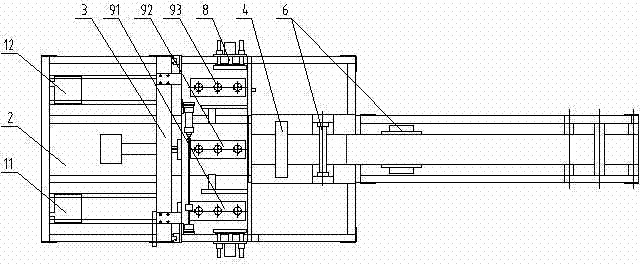

[0039] Such as figure 1 , figure 2 As shown, a new type of full-automatic numerical control plate wrapping machine, including plate conveying device 1, plate ordering device 8, plate lifting device 9, plate absorbing device 3, separator paper conveying device 6, and separator paper cutting device 4. Packing device 5 , plate group conveying device 7 and frame 2 . The pole plate conveying device 1 is installed on the lower left side of the frame 2, and is used to convey the pole plate stack 16; The left and right sides are pressed together; the pole plate lifting device 9 is installed under the frame 2 for lifting the pole plate stack 16 or the pole plate group 75, and cooperates with the pole plate suction device 3 to work. The pole plate suction device 3 is installed above the pole plate lifting device 9, and is used to absorb the pole plate arranged by the pole plate ordering device 8, and transport the pole plate to the plate wrapping device 5 for wrapping; the separator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com