Automatic assembling device and implementation method thereof

A technology for assembling devices and driving devices, which is applied in the field of automation, can solve the problems of multiple manpower and high manpower investment costs, and achieve the effects of reducing personnel costs, improving efficiency, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

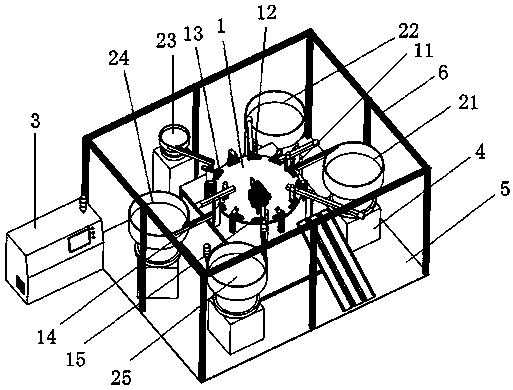

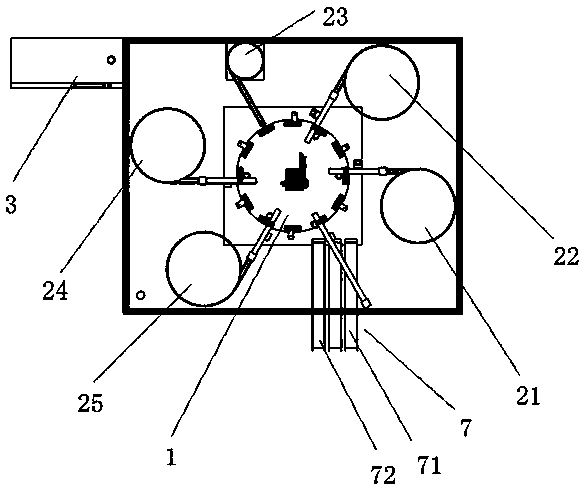

[0051] The invention discloses an automatic assembly device, such as figure 1 with figure 2 As shown, the device includes a turntable 1, and a first station 11, a second station 12, a third station 13, a fourth station 14 and a fifth station 15 are arranged on the circumferential direction of the turntable. The cover of the automatic assembly device is provided with an equipment sealing wall 6, and one side of the equipment sealing wall 6 is provided with an openable pick-and-place window for picking and placing items.

[0052] One side of each sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com