Automatic production line for goods stacking and packaging

An automatic production line and stacking technology, which is applied in the direction of packaging, binding objects, conveyor objects, etc., can solve the problems of low automation, serious health hazards, and large pollution, so as to improve production efficiency, liberate labor force, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

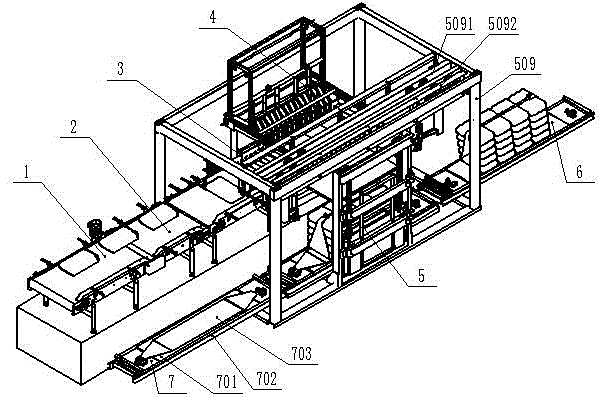

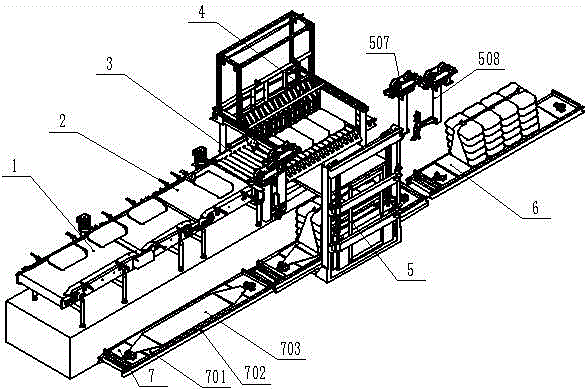

[0023] as attached figure 1 and 2 As shown, the automatic production line for stacking and packaging of goods includes an input mechanism 1, a posture adjustment mechanism 2, an arrangement mechanism 3, a push mechanism 4, a material stacking and packaging mechanism 5, an output mechanism 6, and a pallet input mechanism 7. The input mechanism 1 passes through The roller conveyor or conveyor belt inputs the small bag materials filled upstream to the production line; the posture adjustment mechanism 2 pulls the materials apart for posture adjustment; the arrangement mechanism 3 completes the orderly arrangement of the materials; the push mechanism 4 will The materials are pushed to the next process for stacking and packing; the stacking and packing mechanism 5 is used for stacking and packing the materials, and sends the packed materials to the next process.

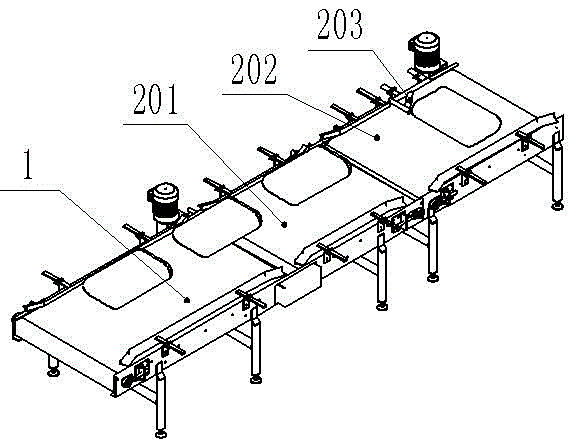

[0024] as attached image 3 As shown, the posture adjustment mechanism 2 includes a pull distance mechanism 201, a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com