Automatic secondary-packaging molding production line

A production line, automatic technology, applied in secondary battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of large personnel input, large production cost, easy safety accidents, etc., to increase the production capacity of the whole machine, Improve production efficiency and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

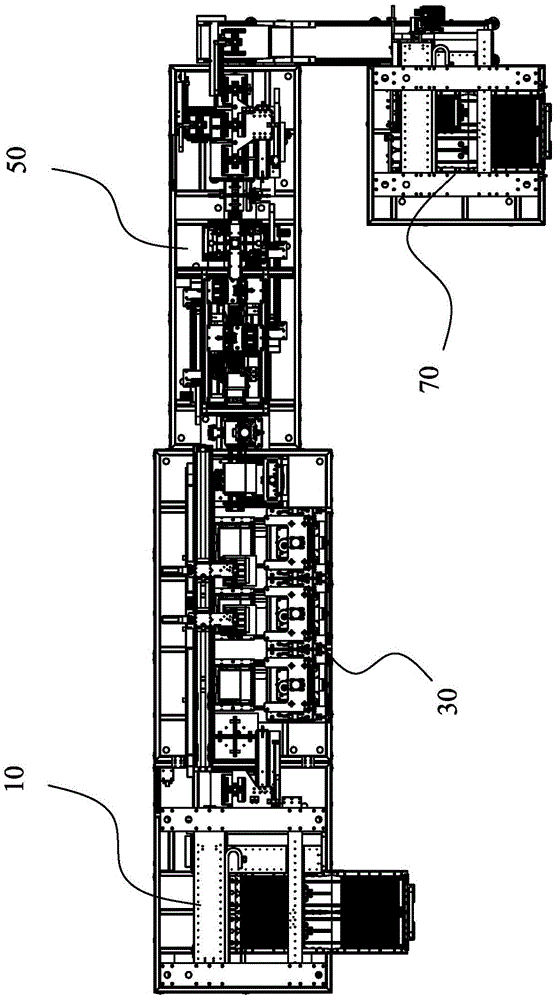

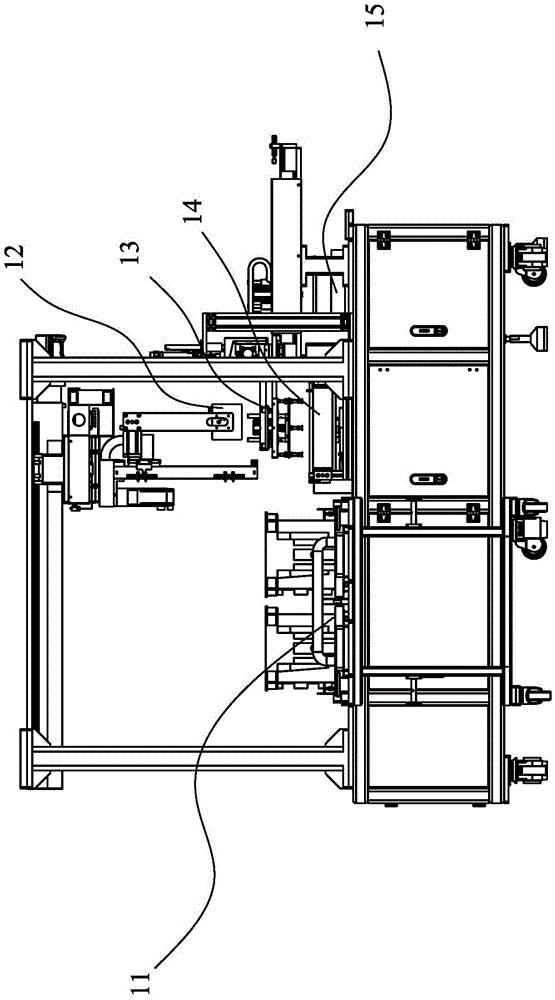

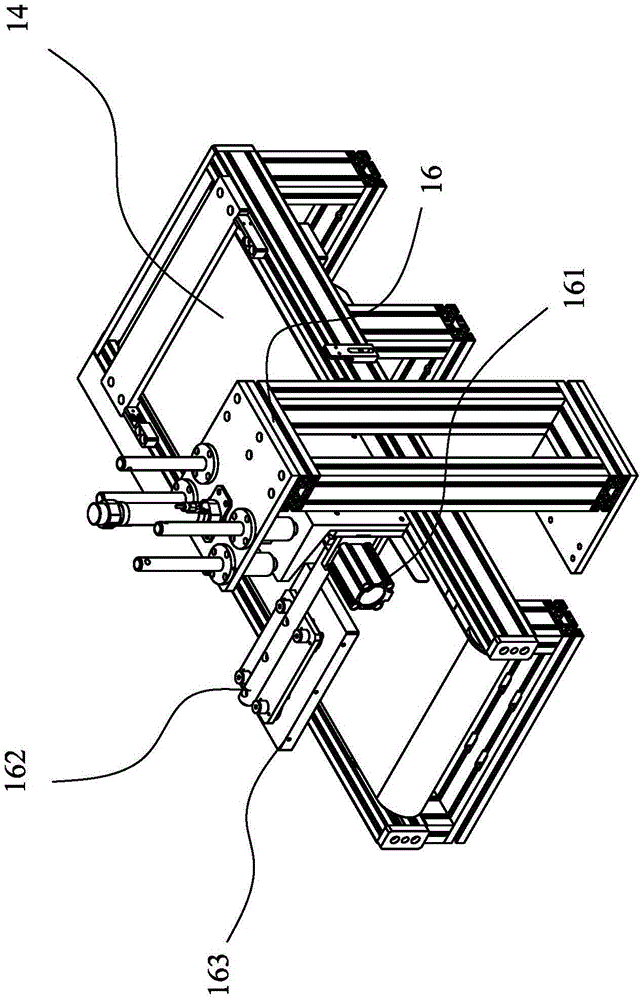

[0027] Such as figure 1 As shown, an automatic two-sealing molding production line includes a feeding unit 10 , a packaging unit 30 , a molding unit 50 and a feeding unit 70 arranged in the direction of cell conveyance. The feeding unit 10 includes a feeding trolley 11 and a feeding pull belt 14, the feeding trolley 11 is provided with a tray for storing batteries, and the front end of the feeding pulling belt 14 is provided with a feeding trolley. 11 compatible loading fixing position and a retrieving mechanism for transferring the battery cells from the feeding tray of the feeding trolley 11 to the feeding pull belt 14, the rear end of the feeding pull belt 14 is provided with a pair of packaging The first weighing station 15 for weighing the batteries in front and the initial sealing calibration station 31 for calibrating the batteries, and the batteries are transferred to the first weighing station 15 and the initial sealing calibration station 31 respectively The dual ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com