Fully automatic loudspeaker cone pasting machine

A laminating machine and fully automatic technology, which is applied to lamination devices, sensors, electrical components, etc., can solve problems such as waste, potential safety hazards, and low manual operation efficiency, and achieve the effect of improving production efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

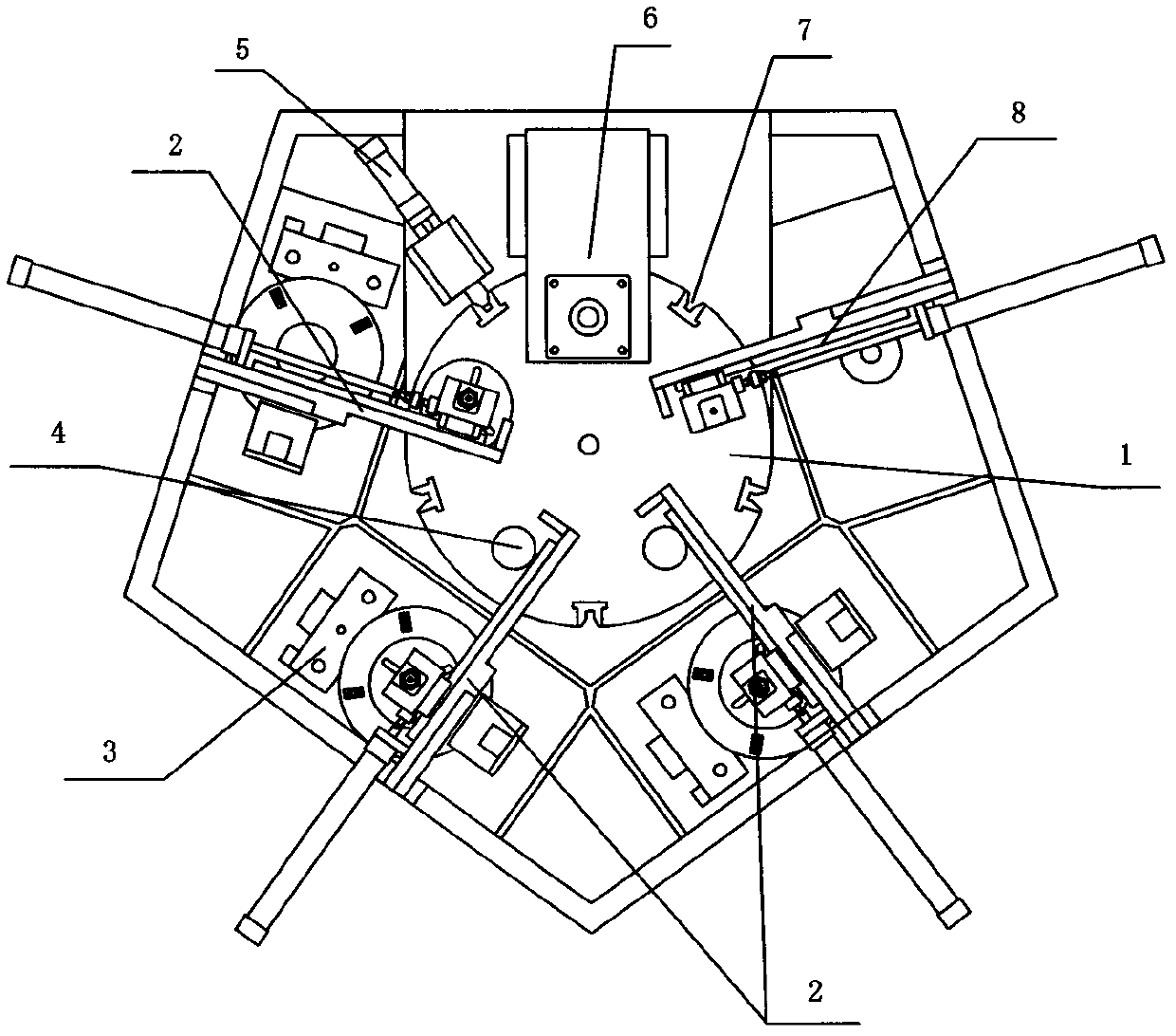

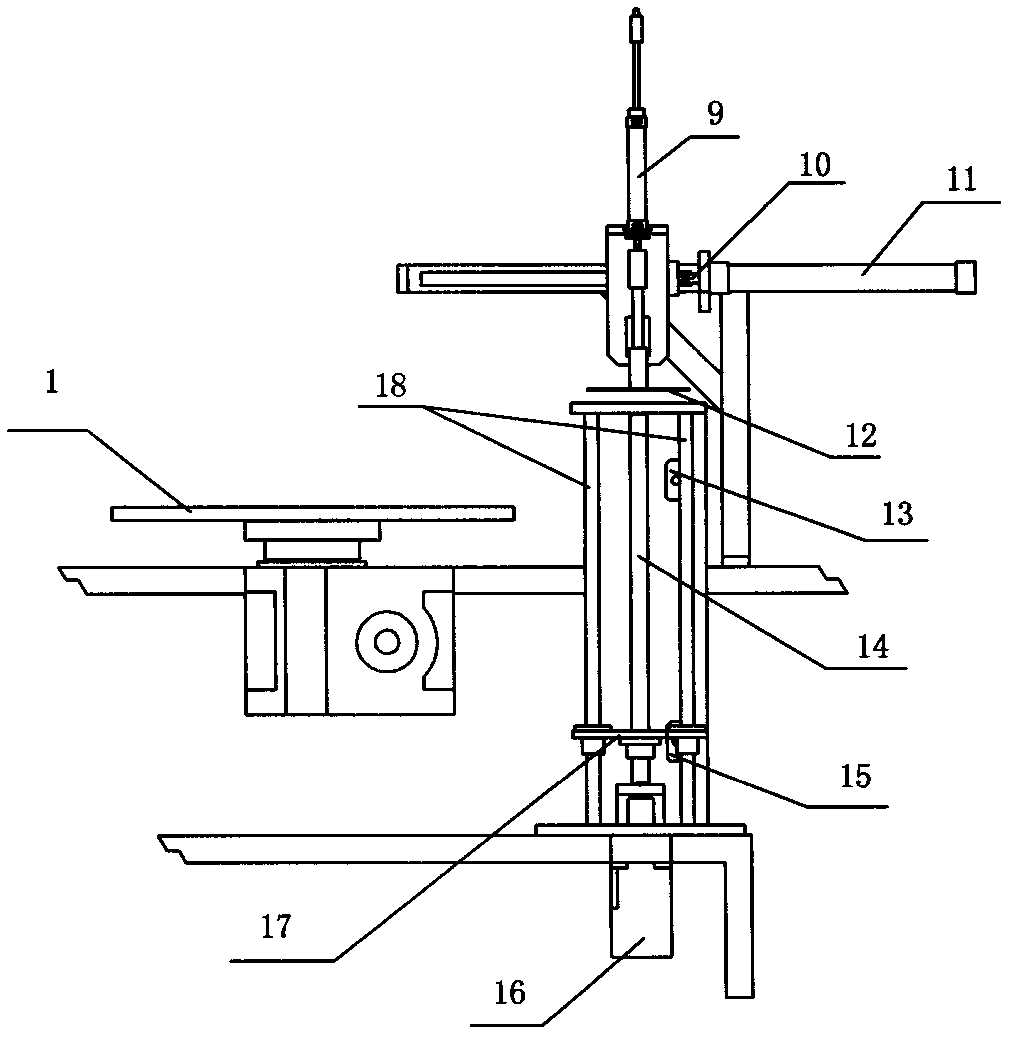

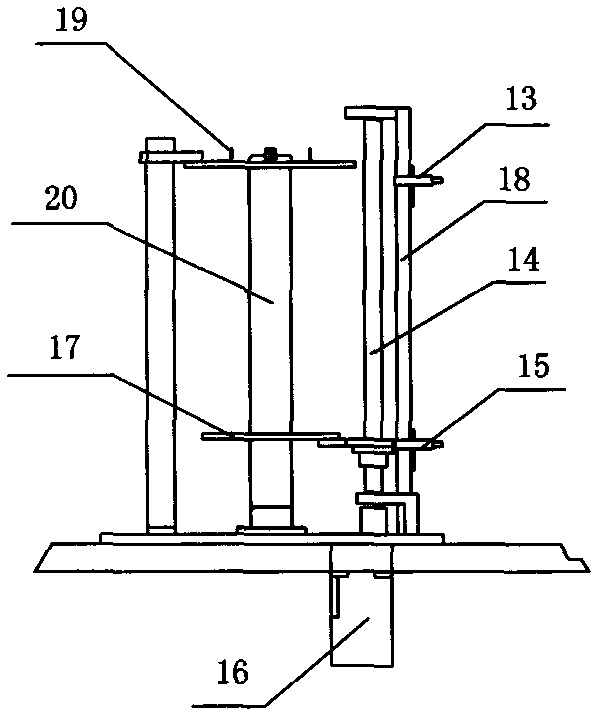

[0020] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a main table top 1, a frame is arranged under the main table top, and the main table top 1 is a circular turntable, and 5 symmetrically arranged stations are arranged on the circular turntable, which are successively the paper cone station and the layering station. position, side setting station, laminating station and finished product station, the lower mold 4 is placed on the station, and the turntable positioning device 5 is fixedly installed on the frame, and the turntable positioning device includes a cylinder and a The positioning head fixedly connected to the piston rod of the cylinder, the positioning groove 7 formed by five gaps is symmetrically arranged on the edge of the circular turntable, and the positioning head extends into the positioning groove 7 to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com