Electric cooker with post-fermentation function and making method of fermented foods

A technology for electric cooking utensils and fermented food, which can be used in household utensils, food science, kitchen utensils, etc., and can solve problems such as stopping work and being unable to use fermented food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

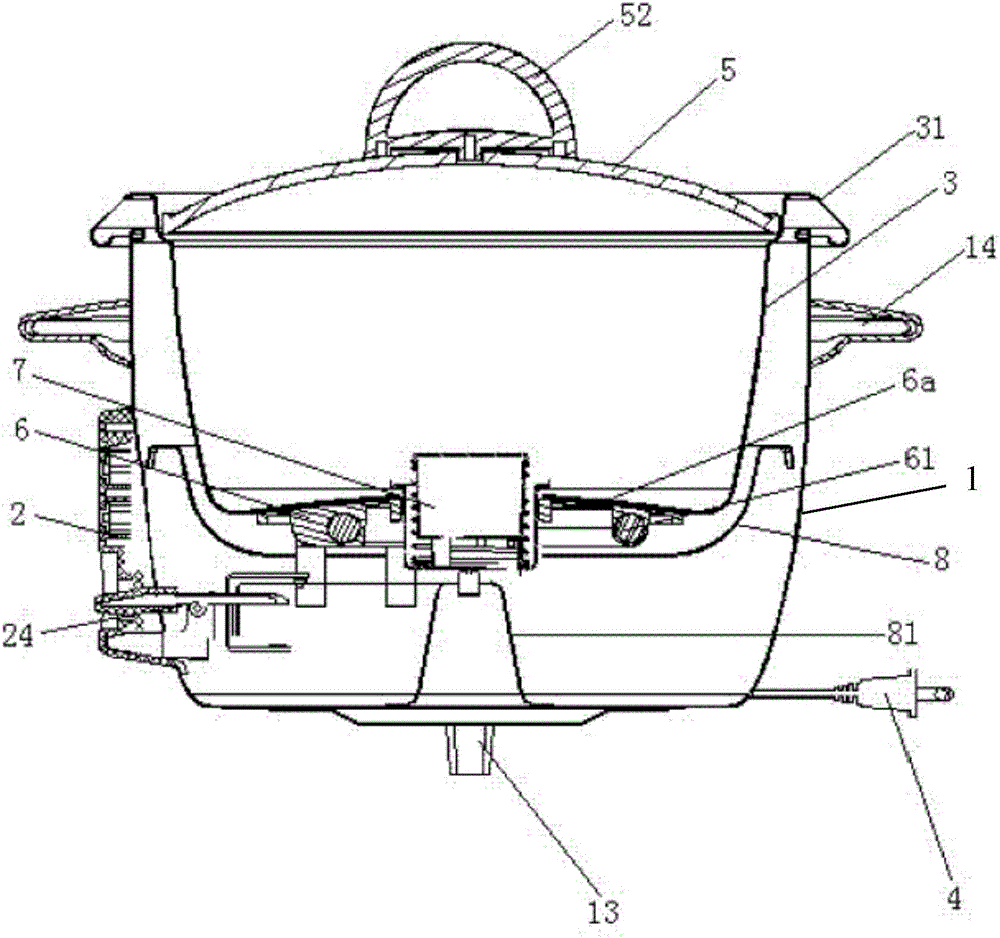

[0086] The fermented food production method provided in this example is to modify the structure of the rice cooker disclosed in ZL201310554429.0 slightly to become an electric cooker with a post-fermentation function, and use the control device on it to control the heating device to heat the inner pot. The food material is made into fermented food, thus completing the production process. figure 1 It is a schematic diagram of the structure of this electric rice cooker, such as figure 1 As shown, this electric cooker mainly includes a pot shell 1, a cooking switch 2, a pot aluminum liner 3, a pot cover 5, a heating plate 6, a support tray 8, a support foot 81 and a control device; wherein the pot shell 1 is provided with a pot Cavity, the pot aluminum liner 3 is housed in the pot cavity, the pot cover 5 is installed on the pot aluminum liner 3, the heating plate 6 is installed at the position below the pot aluminum liner 3 in the pot cavity, the inner surface of the bottom surfa...

Embodiment 2

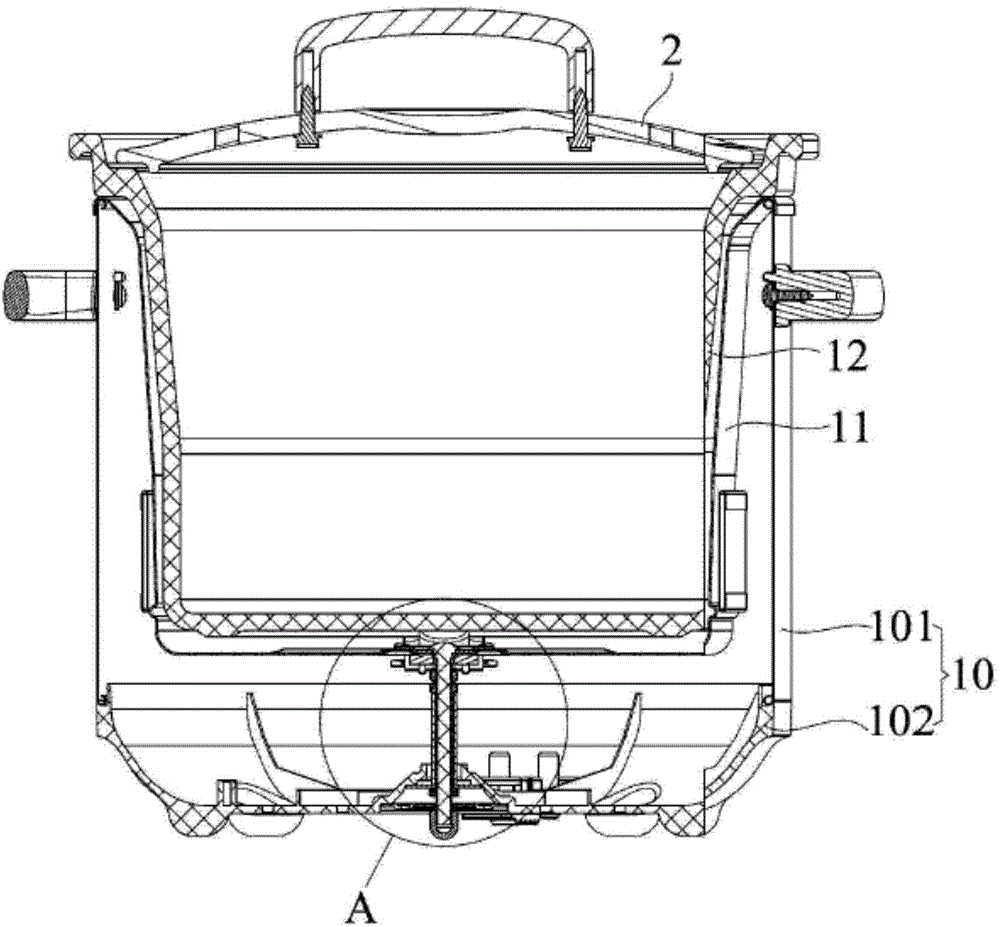

[0092] The fermented food production method provided in this embodiment is to slightly modify the structure of the electric saucepan disclosed in ZL201320471489.1 to become an electric cooker with a post-fermentation function, and use the control device on it to control the heating device to heat the inner pot. The ingredients in the pot are made into fermented food, thus completing the production process. figure 2 It is a schematic diagram of the structure of this electric saucepan, such as figure 2 As shown, this electric saucepan mainly includes a pot body, a pot cover 2, an inner pot 12, a heating device and a control device; wherein the pot body includes an outer pot 11 and a casing 10; the casing 10 includes a side shell 101 and a base 102; The heating device is installed between the outer pot 11 and the casing 10 , while the control device is arranged on the side casing 101 .

[0093] In this embodiment, at least one vent hole is formed on the pot cover 2 of the abov...

Embodiment 3

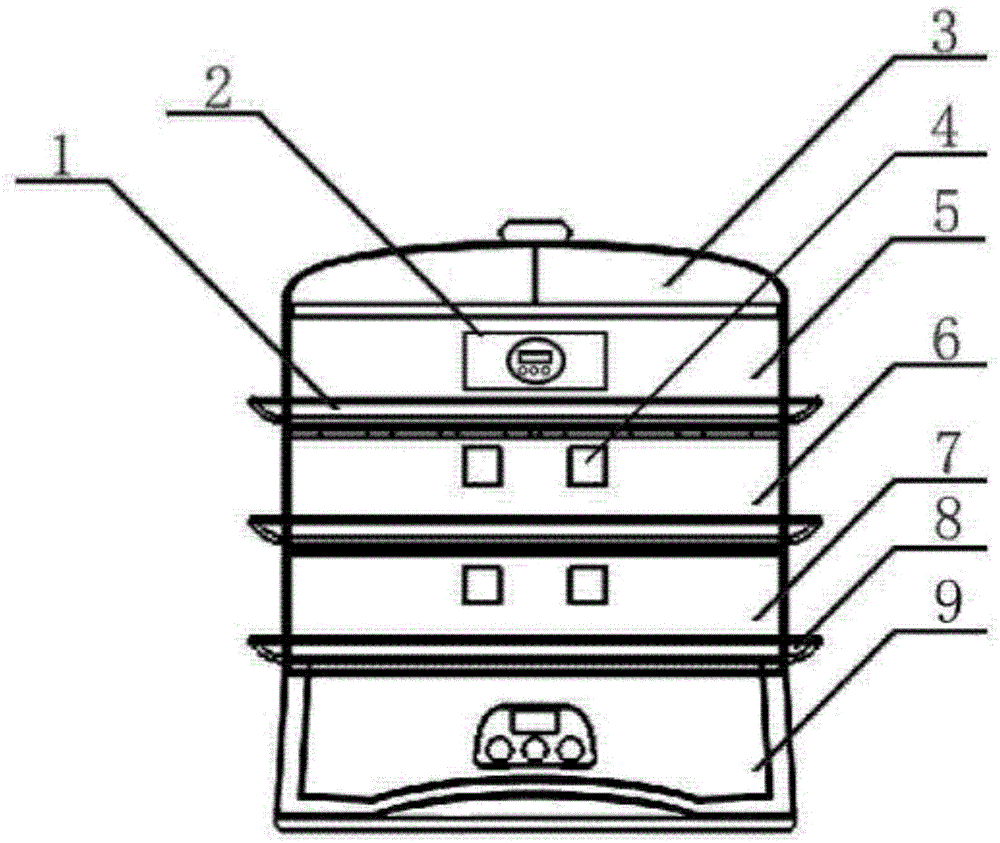

[0098] The fermented food production method provided in this embodiment is to slightly modify the structure of the electric steamer disclosed in ZL201320399015.0 to become an electric cooker with a post-fermentation function, and use the control device on it to control the heating device to heat the steamed food. The food material in the layer (ie steaming tray) is made into fermented food, thereby completing the production process. image 3 It is a schematic diagram of the structure of this electric steamer, such as image 3 As shown, this electric steamer mainly includes a base 9, a steaming layer 1, a pot cover 3, a control device and a heating device; wherein the steaming layer 1 is composed of multi-layer steaming layer units, stacked on the base 9; the pot cover 3 is placed On the steaming layer 1; the control device and the heating device are arranged in the base 9.

[0099]In this embodiment, at least one ventilation hole is formed on the lid 3 of the electric steamer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com