Full-automatic pulp-molding roller molding machine

A pulp molding and forming machine technology, applied in textiles and papermaking, etc., can solve the problems of high labor intensity of workers, increase production costs, low cost performance, etc., and achieve the effects of protecting the environment, saving resources and overcoming waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

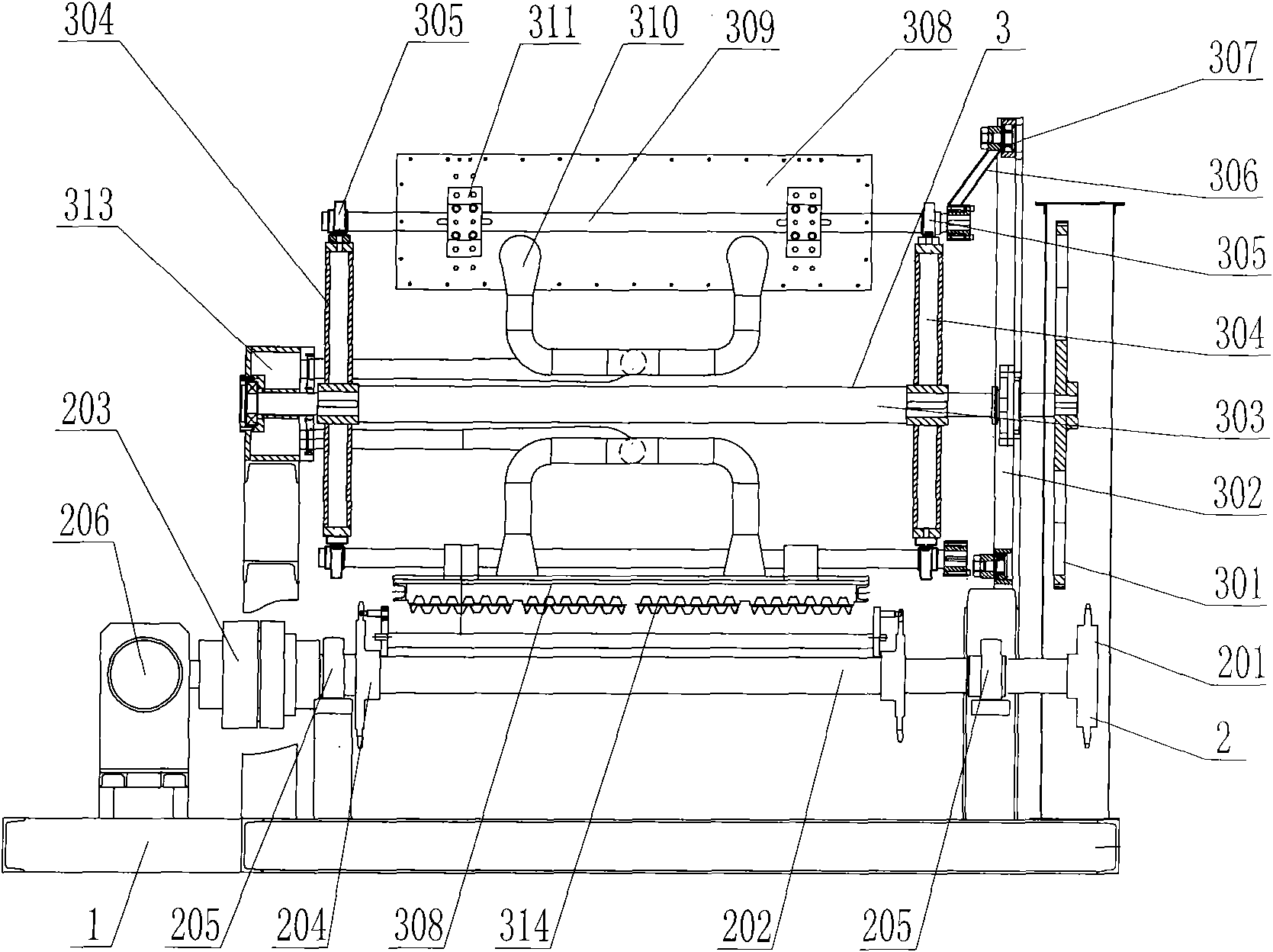

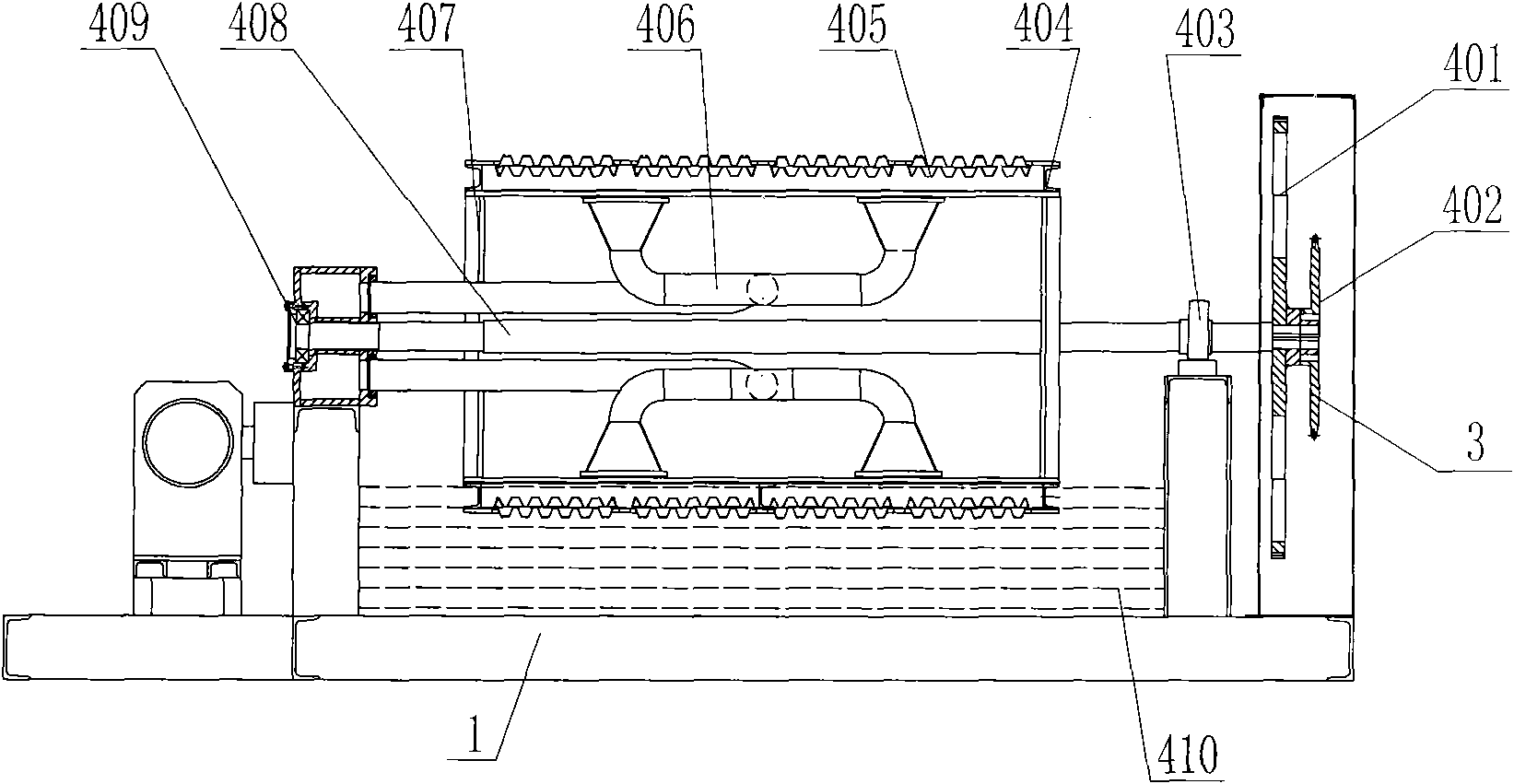

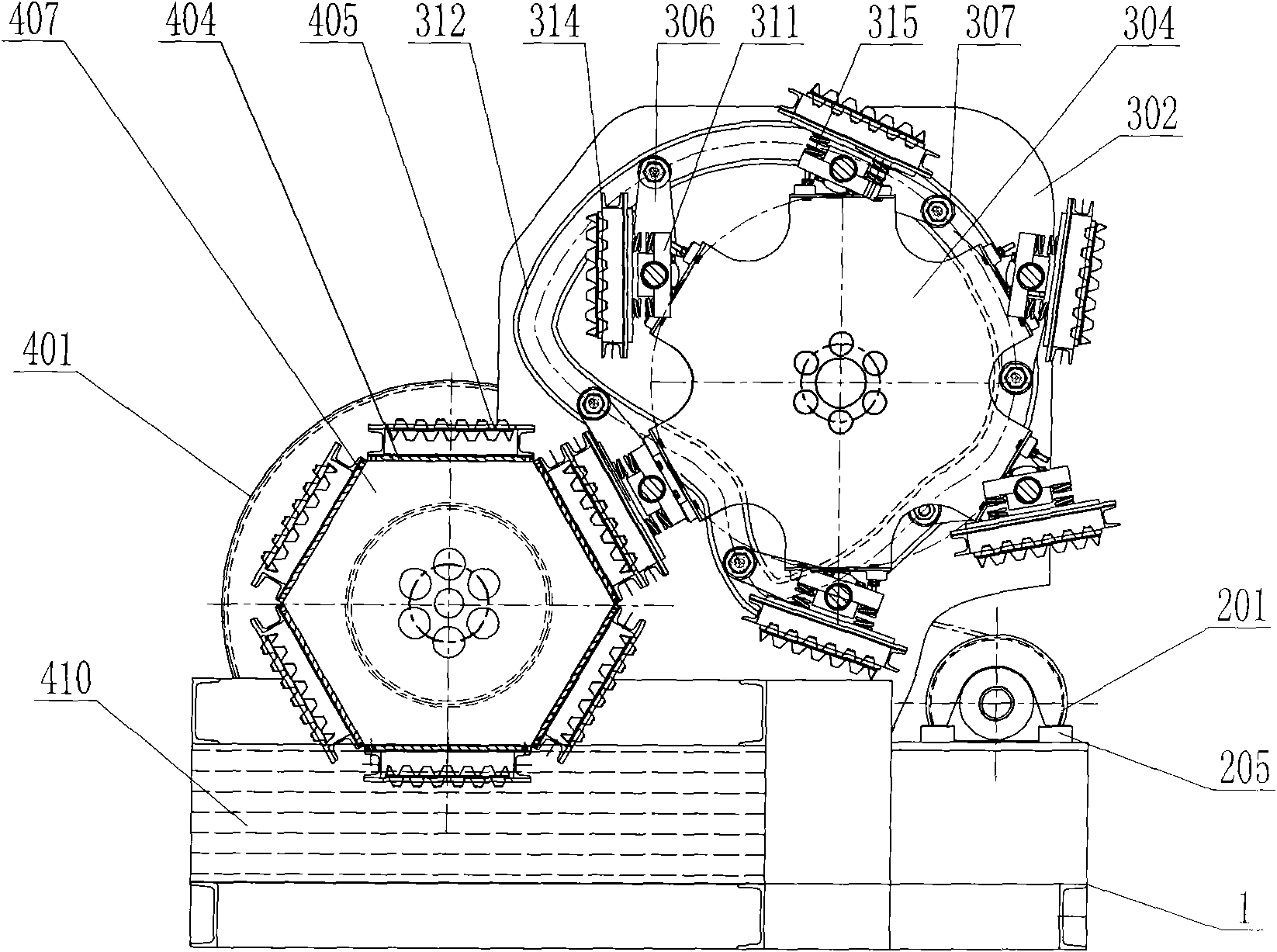

[0025] by attached figure 1 , figure 2 , image 3 , Figure 4 As shown, a fully automatic pulp molding machine is composed of a frame 1, a drying transmission device 2, a transfer drum 3, and a slurry suction drum 4; the drying transmission device 2 includes a small sprocket 201 solid Installed on one end of the transmission shaft 202, the transmission shaft 202 is movably connected with the two bearing seats I205, the other end of the transmission shaft 202 is connected to the speed reducer 203, the speed reducer 203 is connected to the speed regulating motor 206, and two transmission pulleys 204 are fixedly installed on the transmission shaft 202; Drum 3 includes a gear 301 fixed on one end of the upper main shaft 303, one side of the upper main shaft 303 is movably installed on the side frame 302, and the other side is movably installed in the bearing of the pulp distribution box 313, and the two sides of the upper main shaft 303 are fixedly supported Frame 304, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com