Cold-rolled steel coil core welding method based on joint robot

A welding method and robot technology, applied in the field of metallurgy, can solve problems such as personal health hazards, improve welding quality and welding efficiency, save labor costs, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

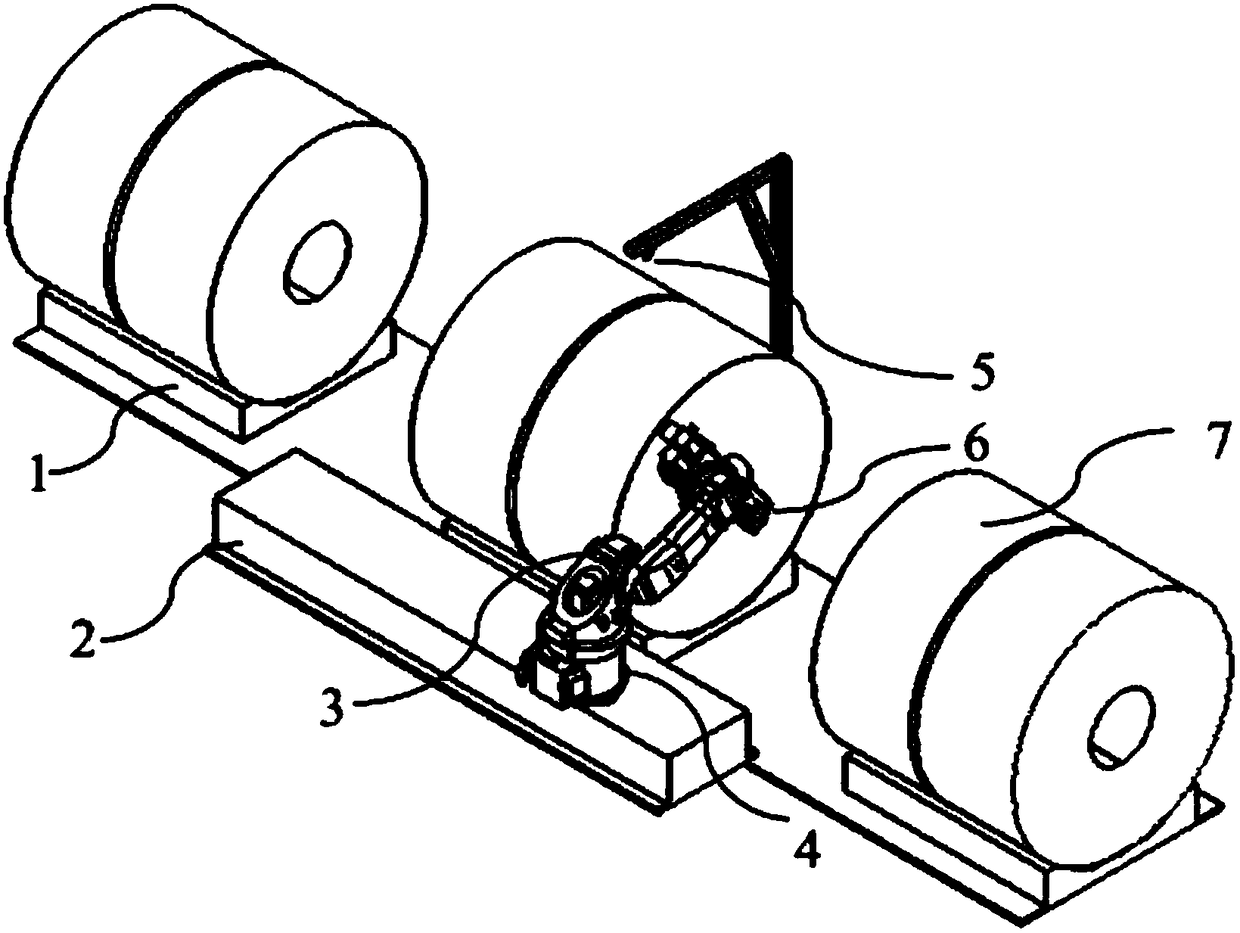

Method used

Image

Examples

specific Embodiment

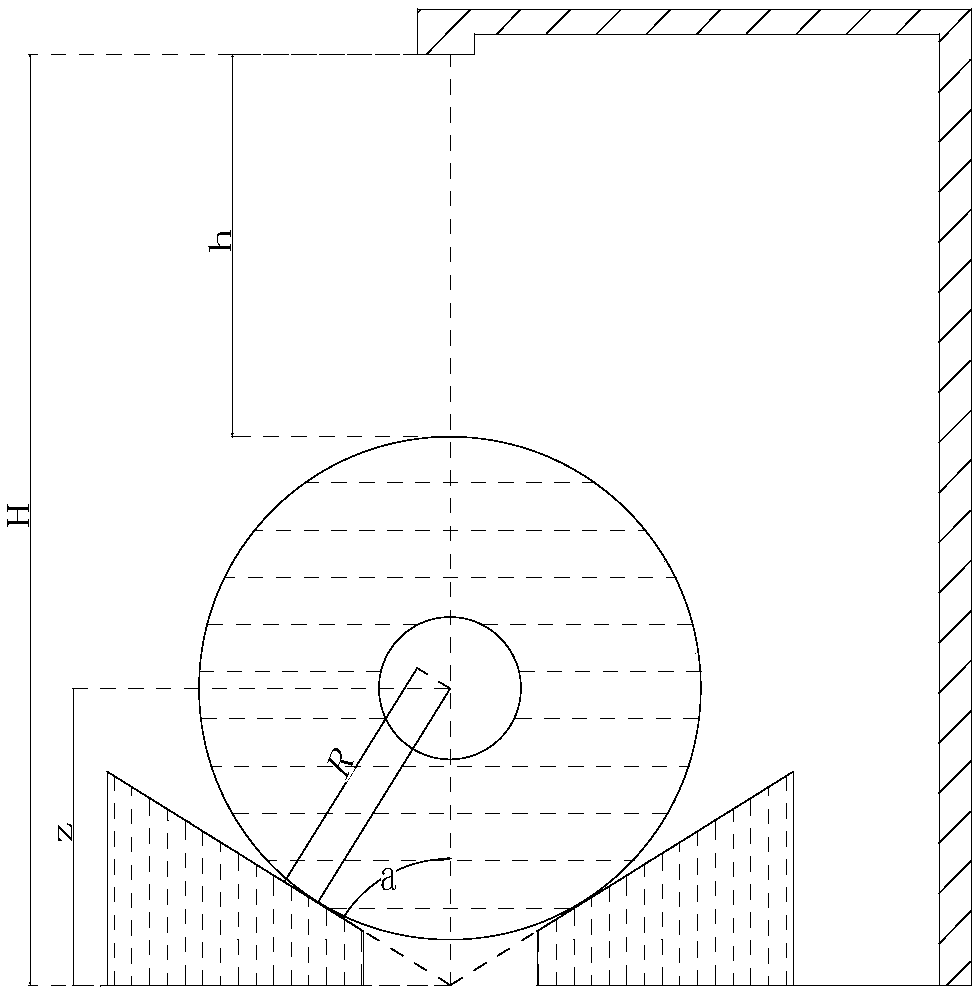

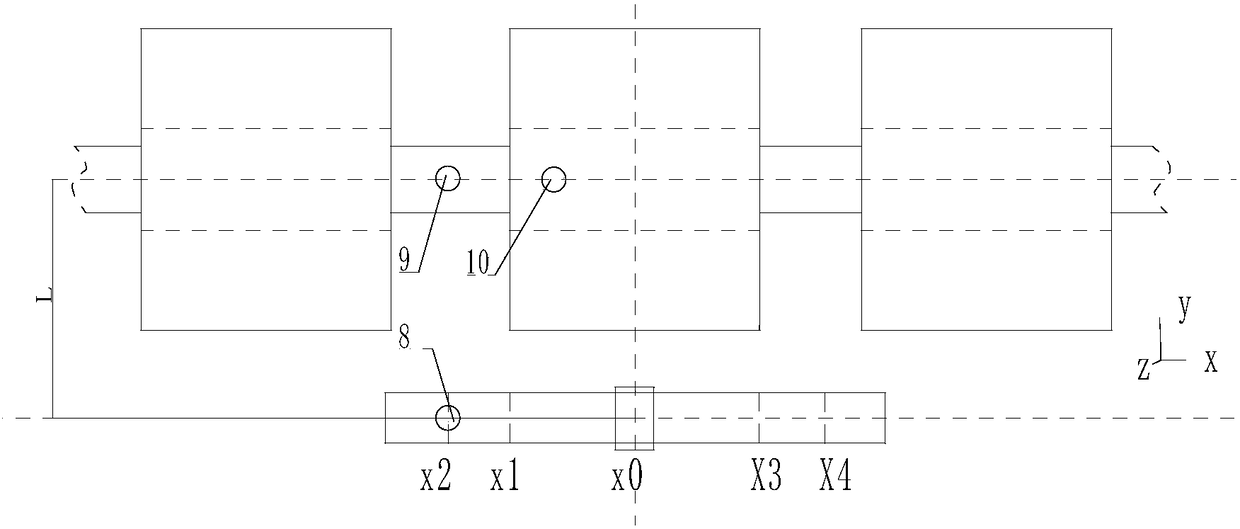

[0033] Steel coil core welding process design: steel coil width 500mm ~ 2000mm, steel coil diameter 1000mm ~ 2000mm, steel strip thickness 0.3mm ~ 3.0mm; resistance spot welding is adopted, the inner ring of the coil core is welded 2 ~ 3 layers, the number of solder joints 2 to 12; the distance from the solder joints to the end face of the steel coil s=50mm to 200mm, and the solder joints are evenly distributed along the circumferential direction of the winding core.

[0034] In this embodiment, the following welding process parameters are used: the width of the steel coil is 1000mm, the diameter of the steel coil is 1200mm, and the thickness of the steel strip is 1.0mm; resistance spot welding is adopted, the inner ring of the coil core is welded in 2 layers, and the number of solder joints is 4; The end face distance s = 100mm, and the solder joints are evenly distributed along the circumferential direction of the winding core.

[0035] Steel coil height detection, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com