Automatic calibration line and method for intelligent type low-tension current transformers

A low-voltage current, transformer technology, applied in the field of power metering and testing, can solve problems such as connection and disconnection errors, poor automation, affecting the verification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

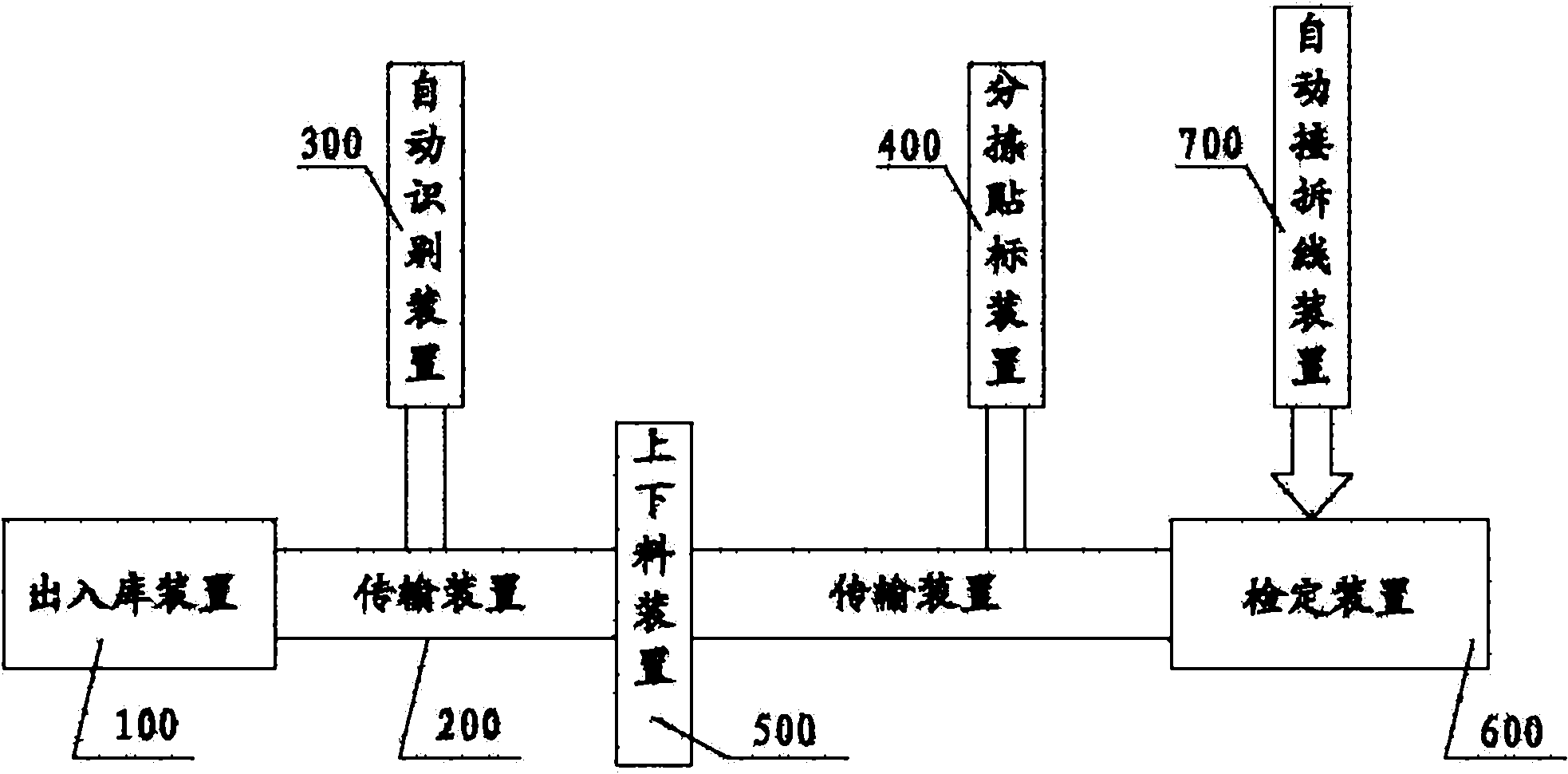

[0083] Such as figure 1 , the intelligent low-voltage current transformer automatic verification line of the present invention includes a storage and storage device 100, a transmission device 200, an automatic identification device 300, a sorting and labeling device 400, a loading and unloading device 500, an automatic connection and disconnection device 700, and a verification device 600 . Combine below figure 1 illustrate.

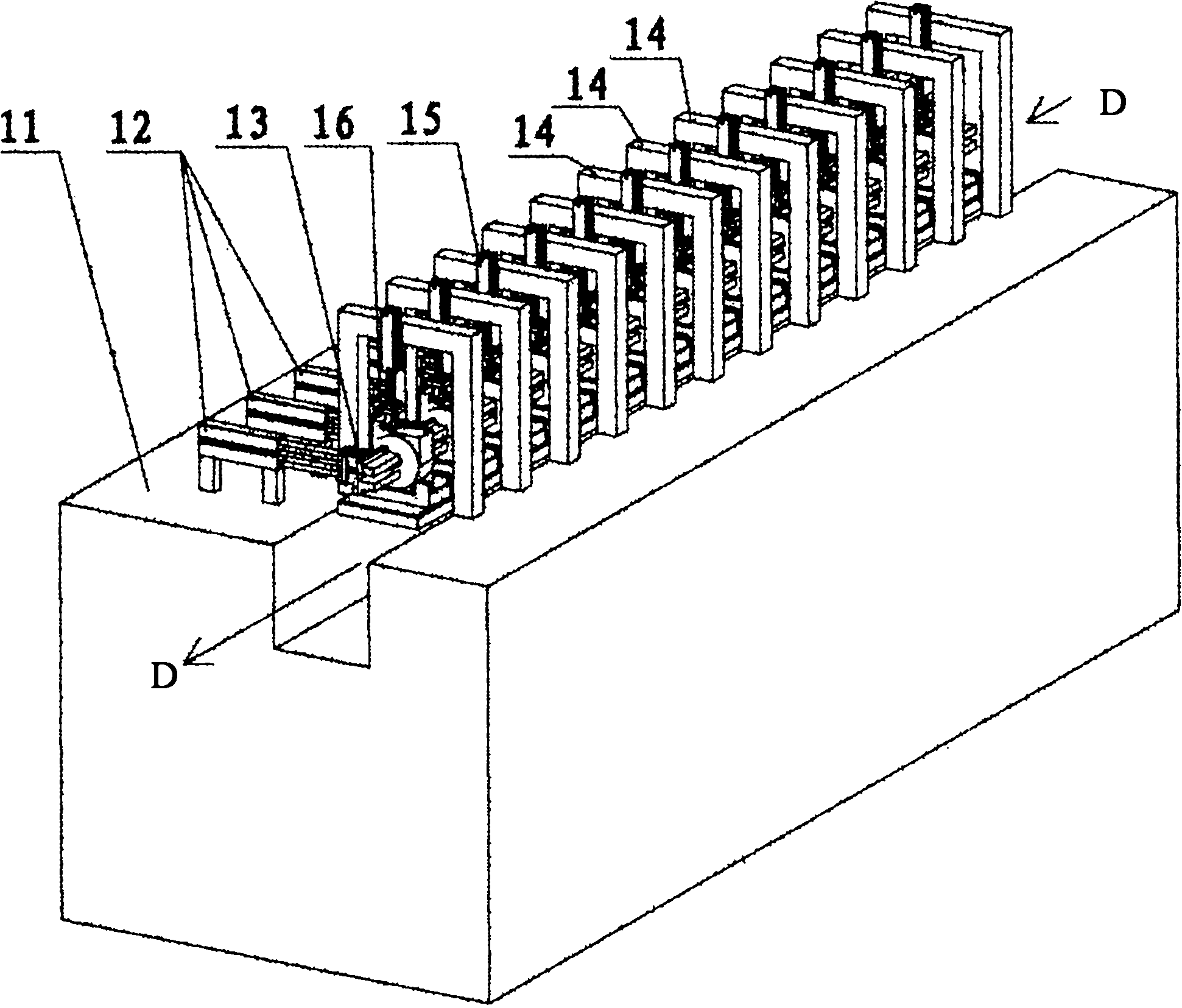

[0084] The warehouse-in and out-out device 100 is used to unstack the stacks of packing boxes output from the logistics warehouse of the transformer before the verification of the verification device, disassemble them into individual packing cases, and place them in the preset position of the outgoing packing boxes, and in the verification device After the verification is completed, multiple pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com