Loading robot

A technology of robots and manipulators, applied in the field of cargo loading and unloading, can solve the problems of incomplete loading automation, incomplete automatic loading, mutual superposition, etc., to achieve the effects of saving manpower, easy unloading, and improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

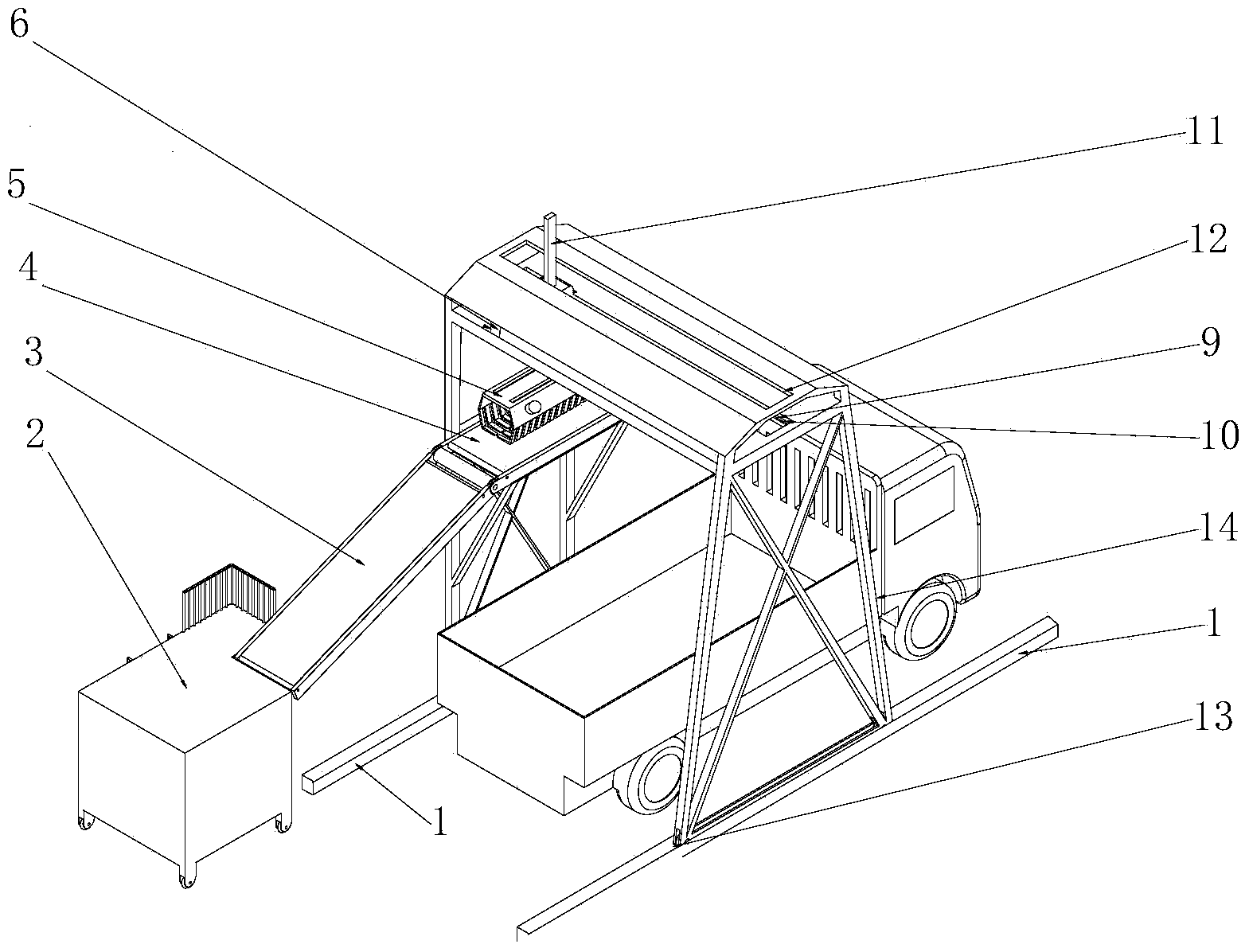

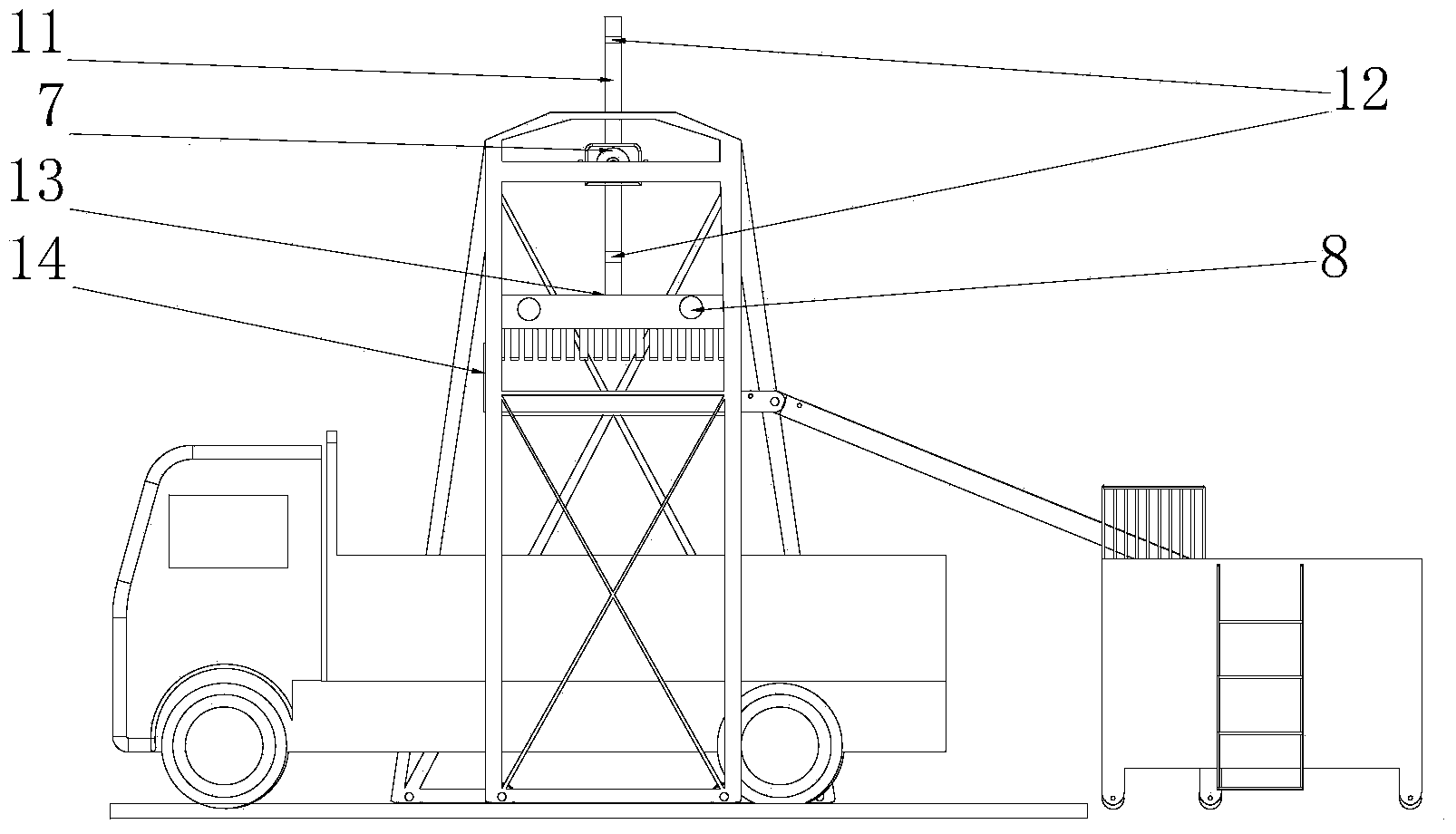

[0040] Such as Figure 1 ~ Figure 2 Shown: a loading robot disclosed in this embodiment, including

[0041] A main body frame 6 for fixing various mechanisms and other components;

[0042] A manipulator 5 for rotating and grabbing goods;

[0043] An up and down movement mechanism 11, connected to the upper end of the manipulator 5, used to drive the manipulator 5 to move up and down;

[0044] A left and right moving mechanism 9 is installed on the upper end of the main frame 6 and connected to the up and down moving mechanism 11 through the slider 10 to drive the manipulator 5 to move left and right;

[0045] A power pack 7 includes a rotary servomotor for controlling the rotation of the manipulator 5, a vertical servomotor for controlling the movement of the vertical movement mechanism 11, and a left and right servomotor for controlling the movement of the left and right movement mechanism 9;

[0046] An inductive control device, including a cargo position sensor, a blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com