Automatic feeding, testing and sorting system and operation method thereof

A sorting system and automatic material feeding technology, which is applied in the fields of communication and electronic product manufacturing, to reduce the number of equipment visits, solve data collection and uploading, and improve computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

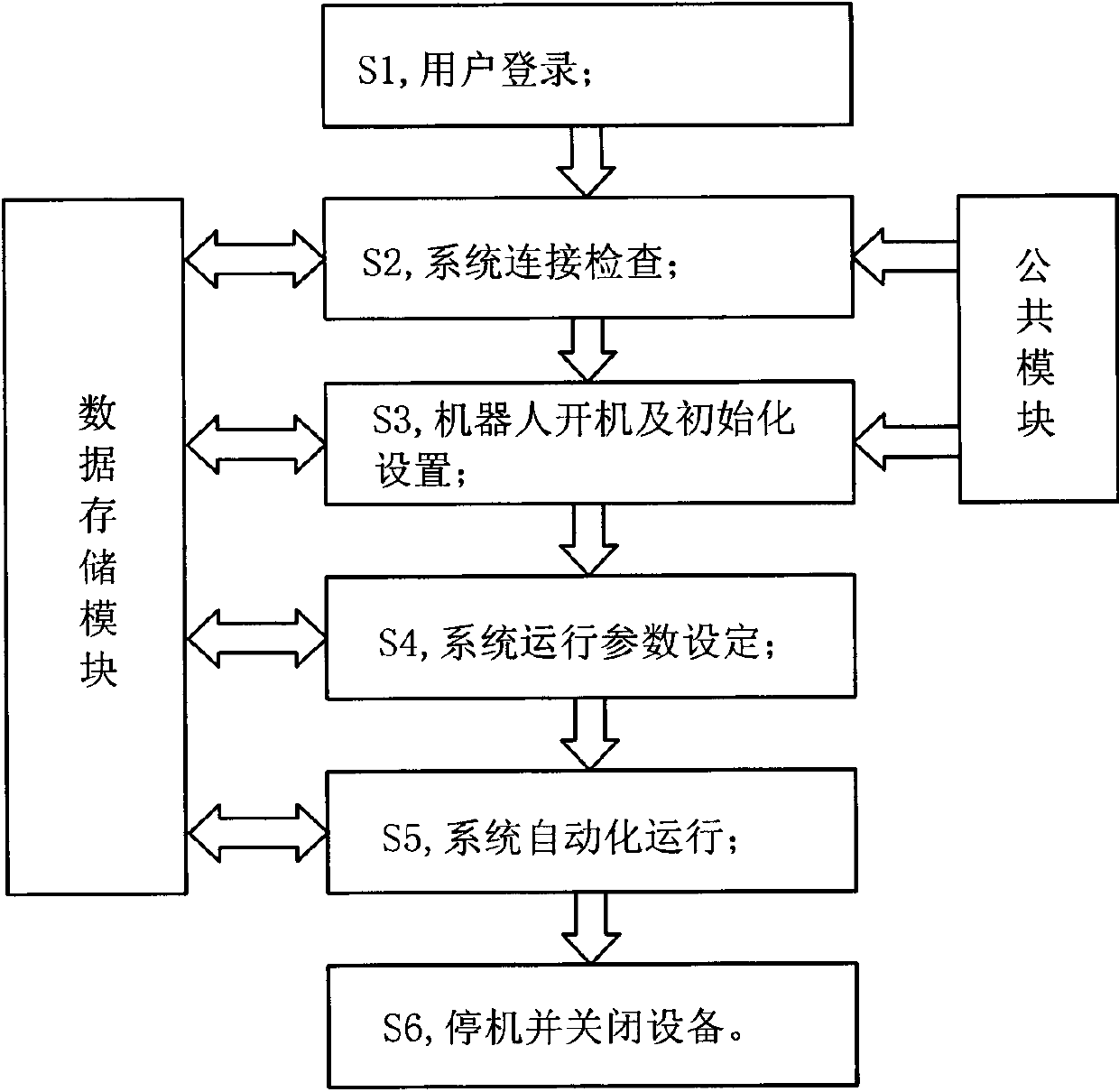

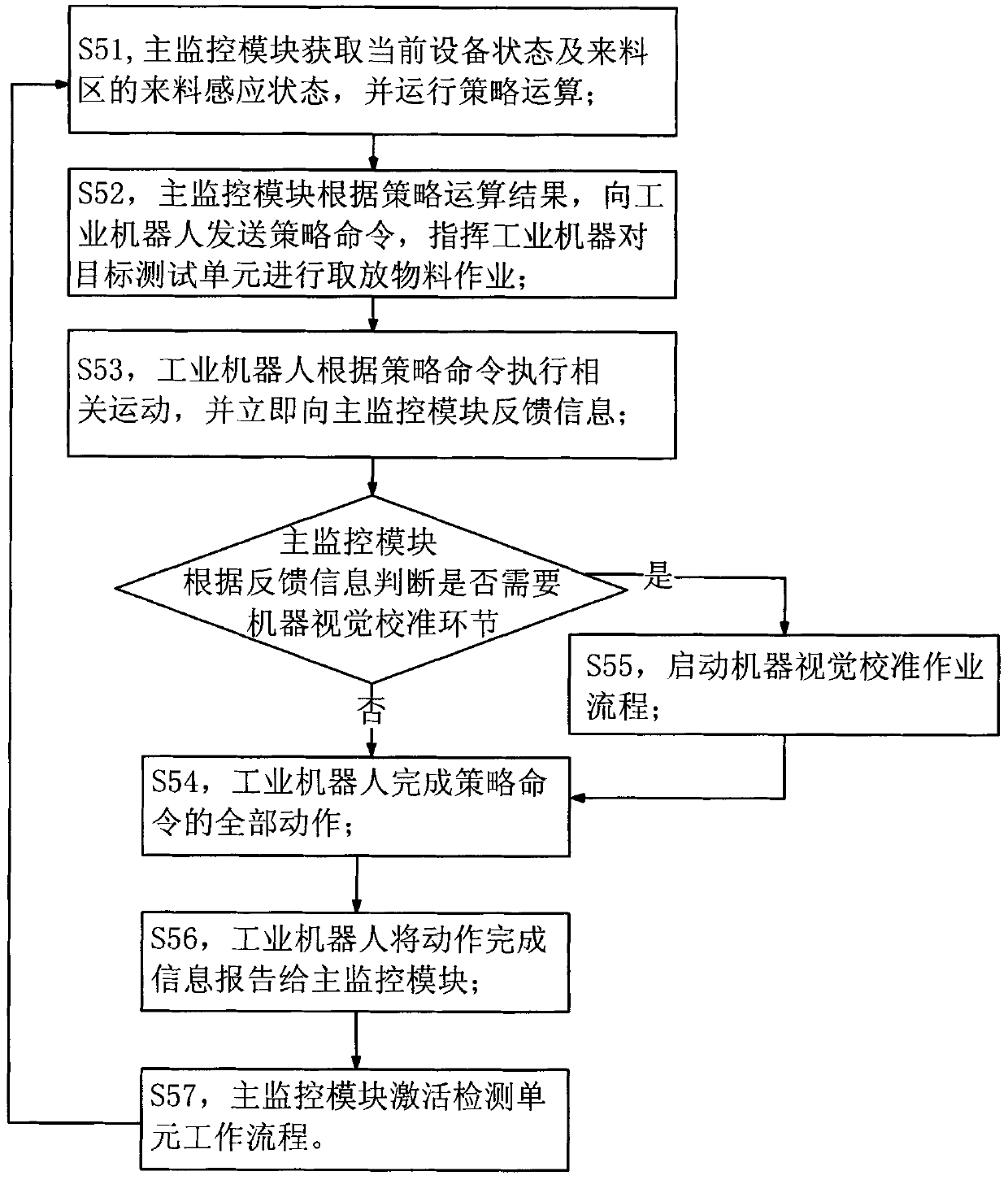

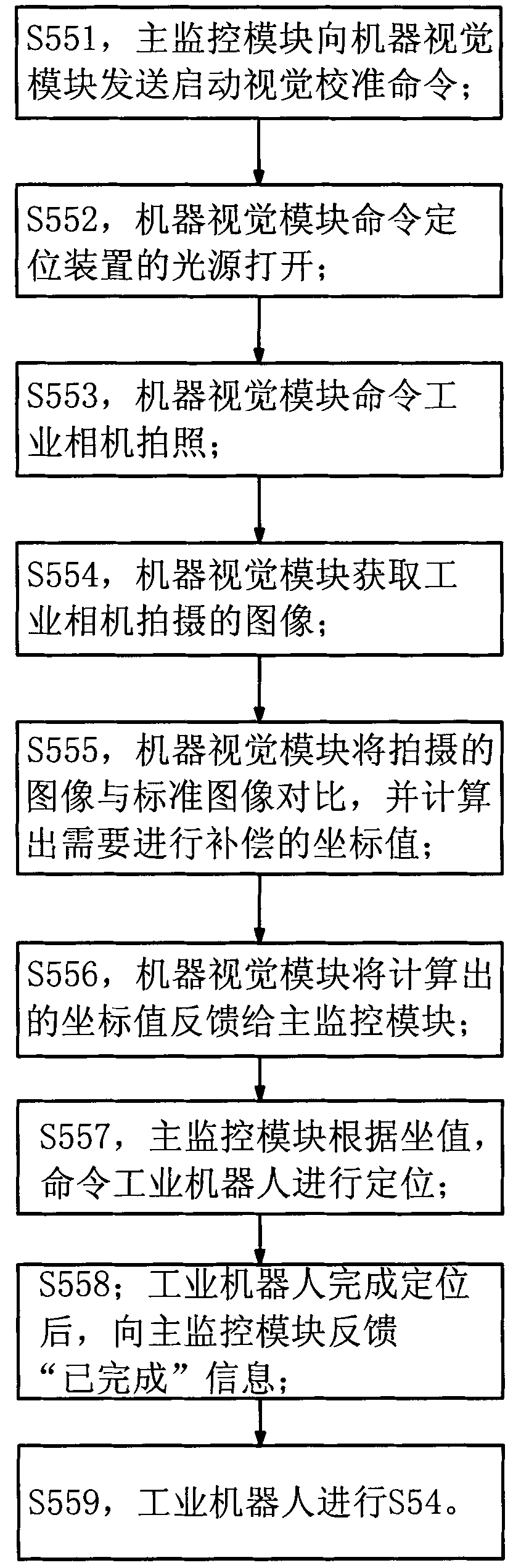

[0070] For the operation method of the automatic feeding, testing and sorting system provided by the present invention, please refer to Figure 1 to Figure 5 , including the following steps:

[0071] S1, user login;

[0072] S2, system connection check, including checking the connection status of PLC, checking the connection status of the test container and checking the connection status of the test computer, and judging whether there is a device that fails to connect according to the detected situation, if so, remind the user to deal with it on the main monitoring interface, if otherwise Go directly to the next step; in this step, you can call the required program from the public module of the thread program with global properties, or call or rewrite the key variables required by the system running in the data s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com