AutomaticSteel bar on-line steel barautomatic counting and splitting system

An automatic counting and bar technology, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems that restrict the application and promotion of the bar counting and separating system, difficulty in achieving accuracy, and imperfect steel separating equipment. Achieve huge practical application value, save manpower, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

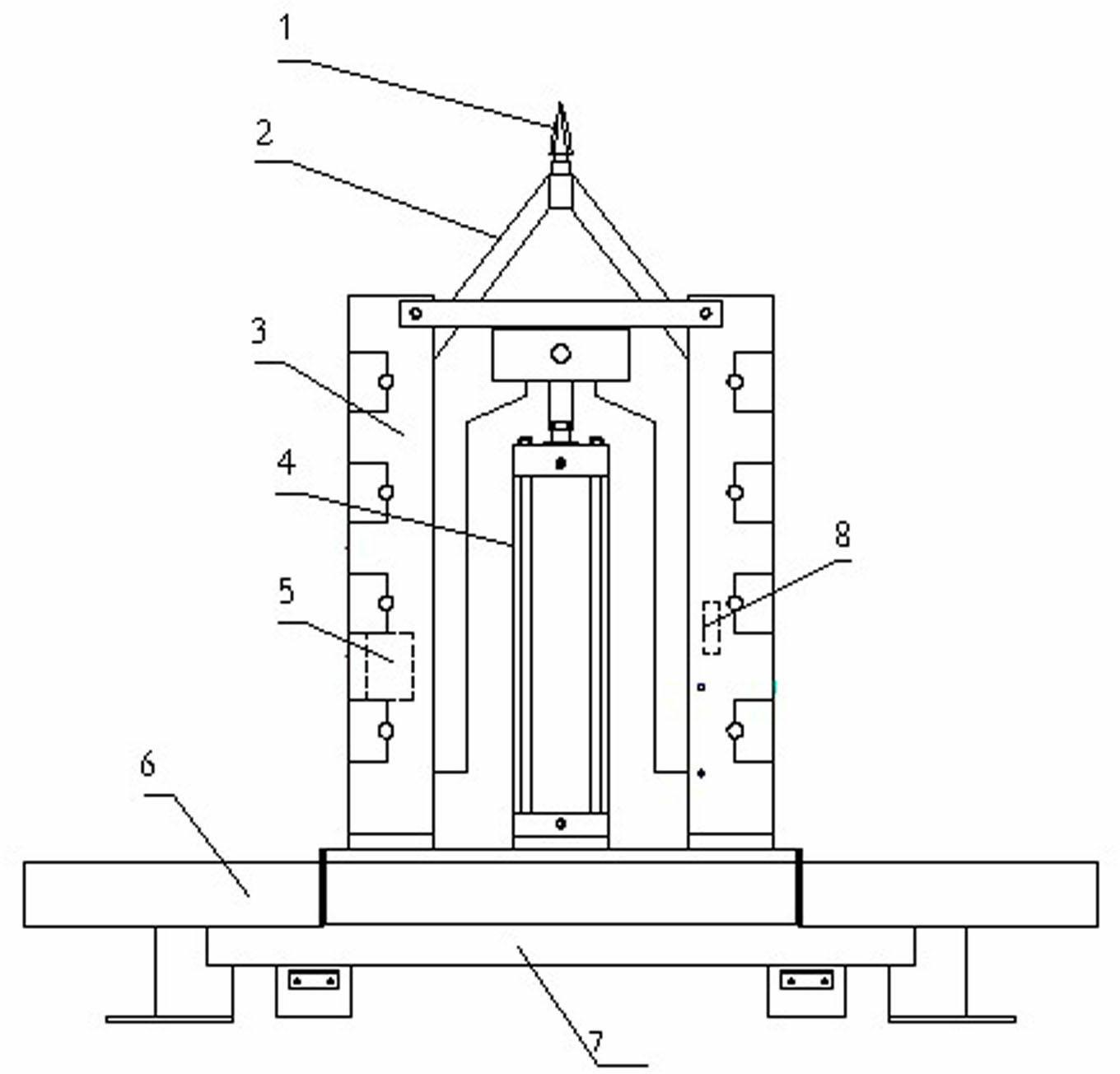

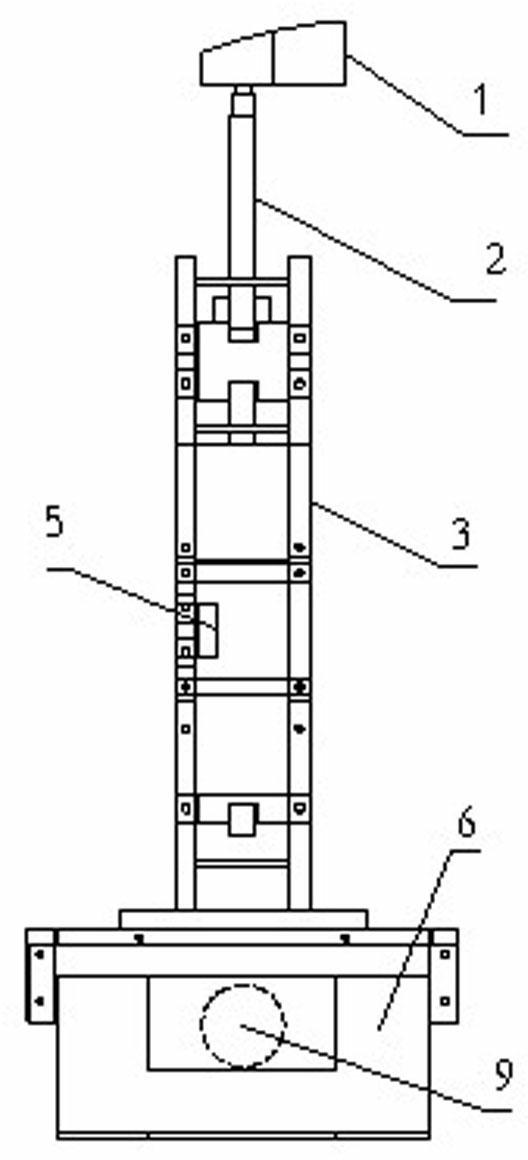

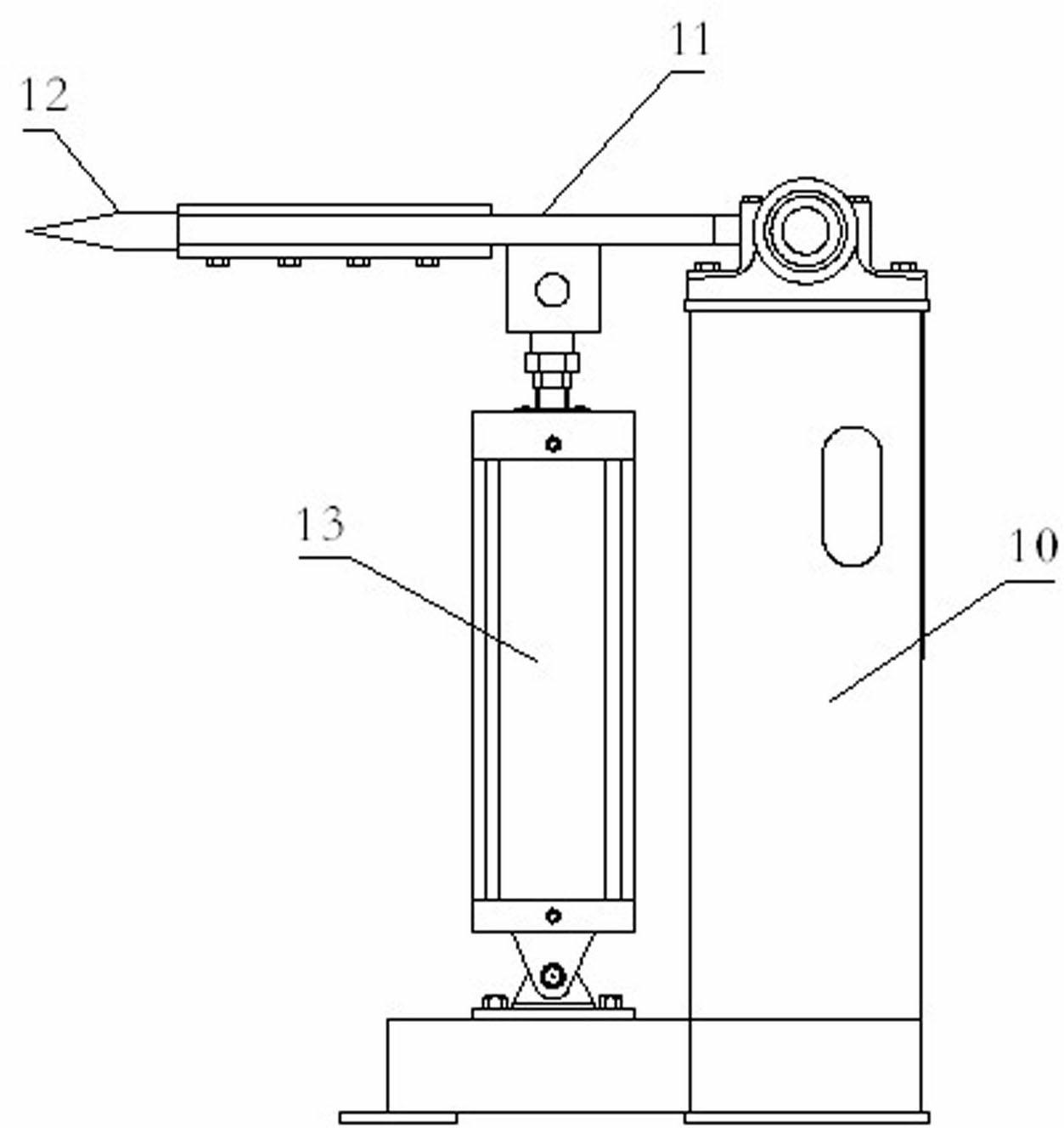

[0029] Such as figure 1 , 2 , 3, 4, 5, and 6 show: a bar online automatic counting and steel division system of the present invention,

[0030] Including automatic counting system and automatic steel sorting system, automatic steel sorting system includes end steel sorting machine A, follow-up complete steel sorting machine B and steel sorting visual feedback system.

[0031] The end steel splitter A is arranged on the outside of the conveyor chain, including a base 6, which is provided with a transverse guide

[0032] Rail 7, servo motor 9 and transmission device, the servo motor 9 is driven and connected with the gate-shaped guide frame 3 that can move along the horizontal guide rail 7 through the transmission device, and the gate-shaped guide frame 3 is provided with arc-shaped guide grooves and longitudinal telescopic power device I4 , the edge of the sub-steel wedge 2 is provided with an arc-shaped guide wheel that matches the guide groove, and the top of the telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com