Coal-cutter roller automatic height-adjusting system

A shearer drum and shearer technology, which is applied to cutting machinery, earthwork drilling, slitting machinery, etc., can solve the problem of not automatically adjusting the height, and achieve the effect of avoiding application restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

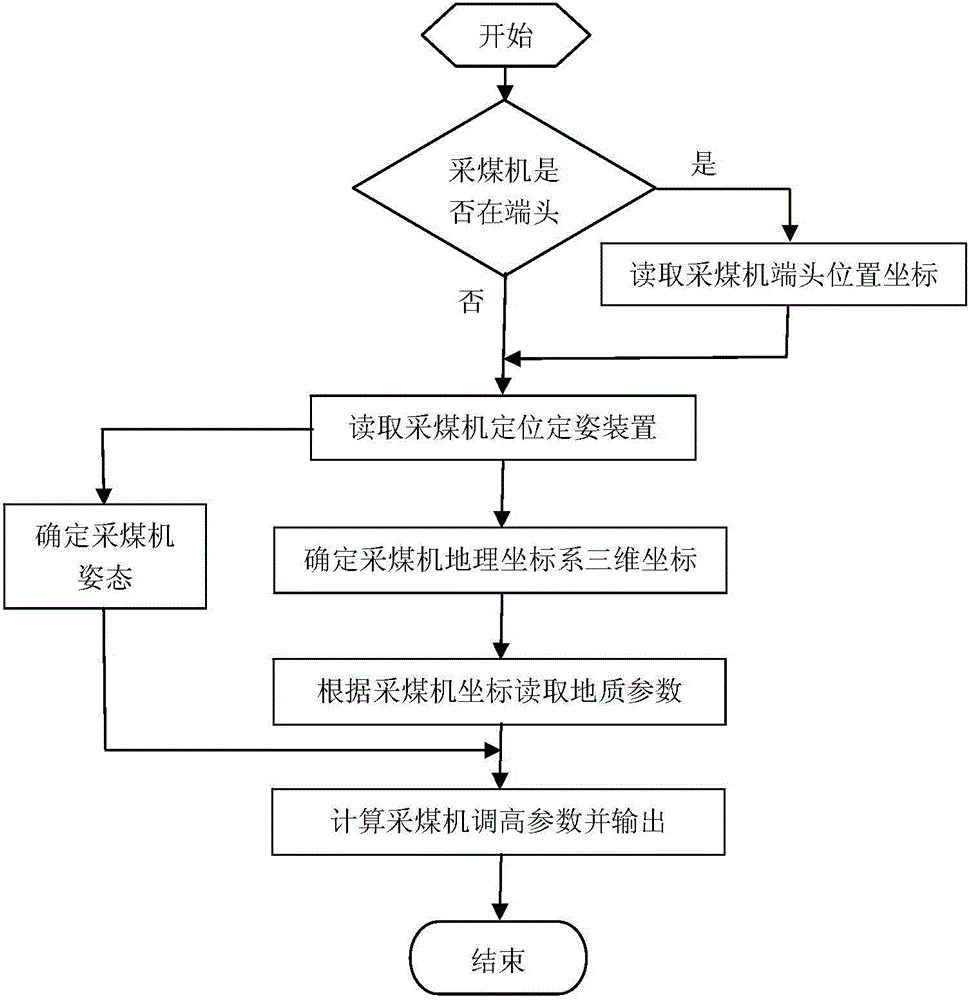

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

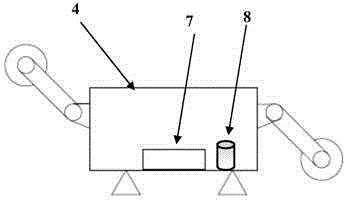

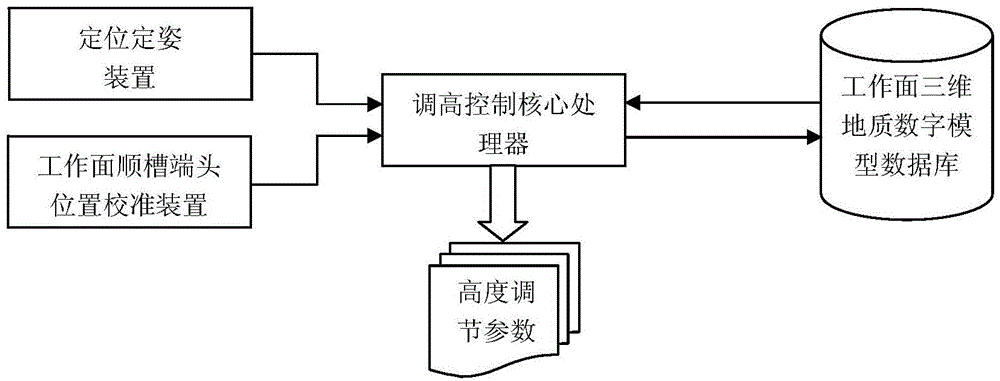

[0024] Such as figure 1 , figure 2 Shown is an automatic height adjustment system for a shearer drum, including a positioning and attitude determination device, a device for calibrating the position of the end of the working face along the trough, a database of three-dimensional geological digital models of the working face, and a core processor for height adjustment control, in which:

[0025] The positioning and attitude determination device uses the combination of the inertial navigation element and the shaft encoder of the shearer walking part to measure the position and attitude of the shearer in real time under the coordinate system of the shearer carrier, and converts the shearer to The coordinates in the carrier coordinate system are transformed into the coordinates in the geographic coordinate system to realize the determination of the position and attitude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com