Automatic coal rock identification method based on multi-tranducer data fusion

A data fusion and multi-sensor technology, applied in the direction of driving devices, earthwork drilling, slitting machinery, etc., can solve the problems of top and bottom coal remaining thick, lower recovery rate, and lower quality of raw coal, so as to improve efficiency and recovery rate , realize the effect of automatic height adjustment and reduce downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

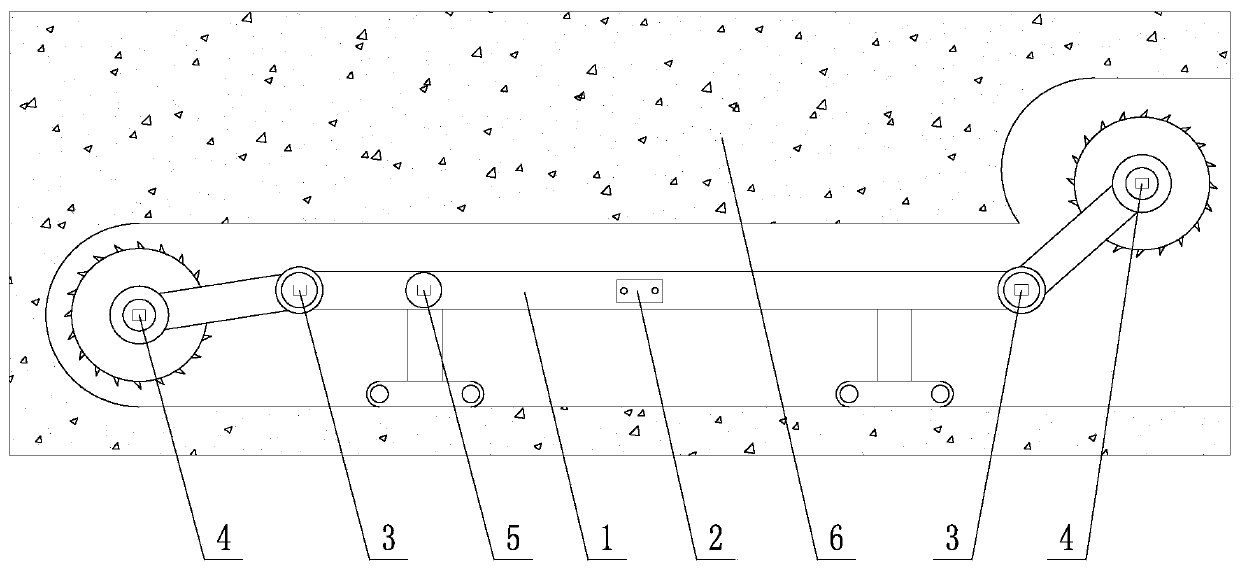

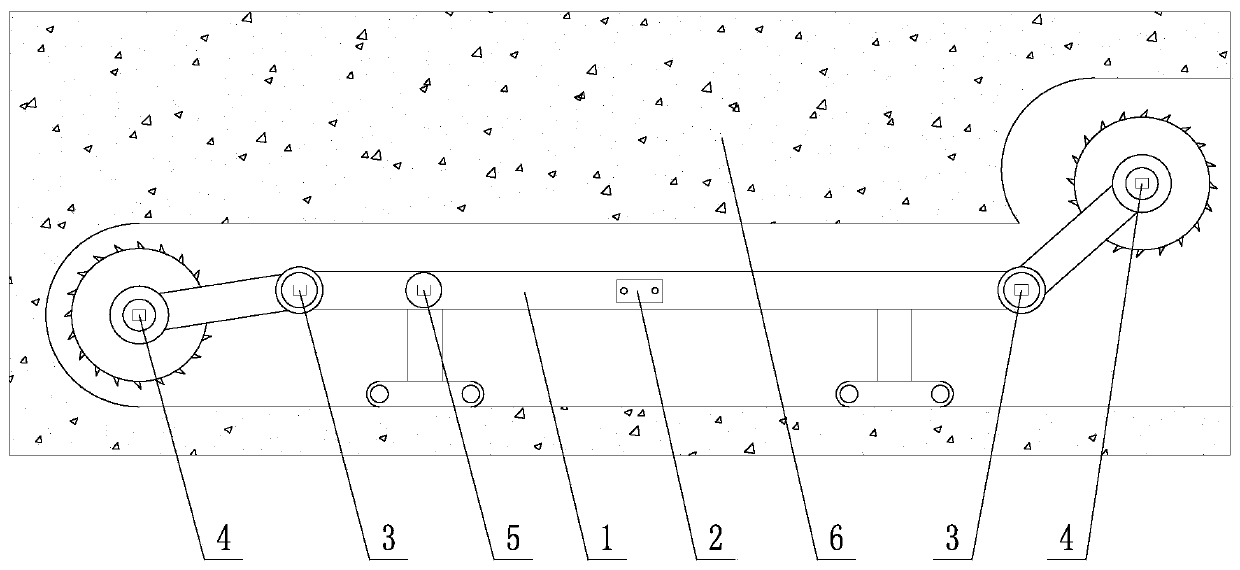

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] In this embodiment, the sensitivity of the piezoelectric acceleration sensor 3 is 35 pC / g, the frequency range is 0.2 Hz to 8000 Hz, the maximum lateral sensitivity ratio is less than 5%, there are two types of lead wires at the top and side ends, and the sensor shell is insulated from the ground. It has explosion-proof characteristics; the applicable working environment temperature of the speed torque sensor 4 is 0-55°C, the maximum torque allowed to be measured is 120% of the rated value, and the sensor housing has explosion-proof characteristics; the accuracy level of the Hall high-current sensor 5 is ≤1.0%. F.S, the linearity is better than 0.2%, the frequency characteristic is 0~100kHz, the applicable working environment temperature is -10℃~50℃, and there is no frost when the humidity is 20%~90%. The sensor shell has explos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com