Silin bottle automatic drawing mechanism used for freeze-drying machine

An automatic discharge device and vial technology, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of high labor intensity, increased pollution costs of processing operators, and large pollution sources of sterile drugs. , to achieve the effect of increasing labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

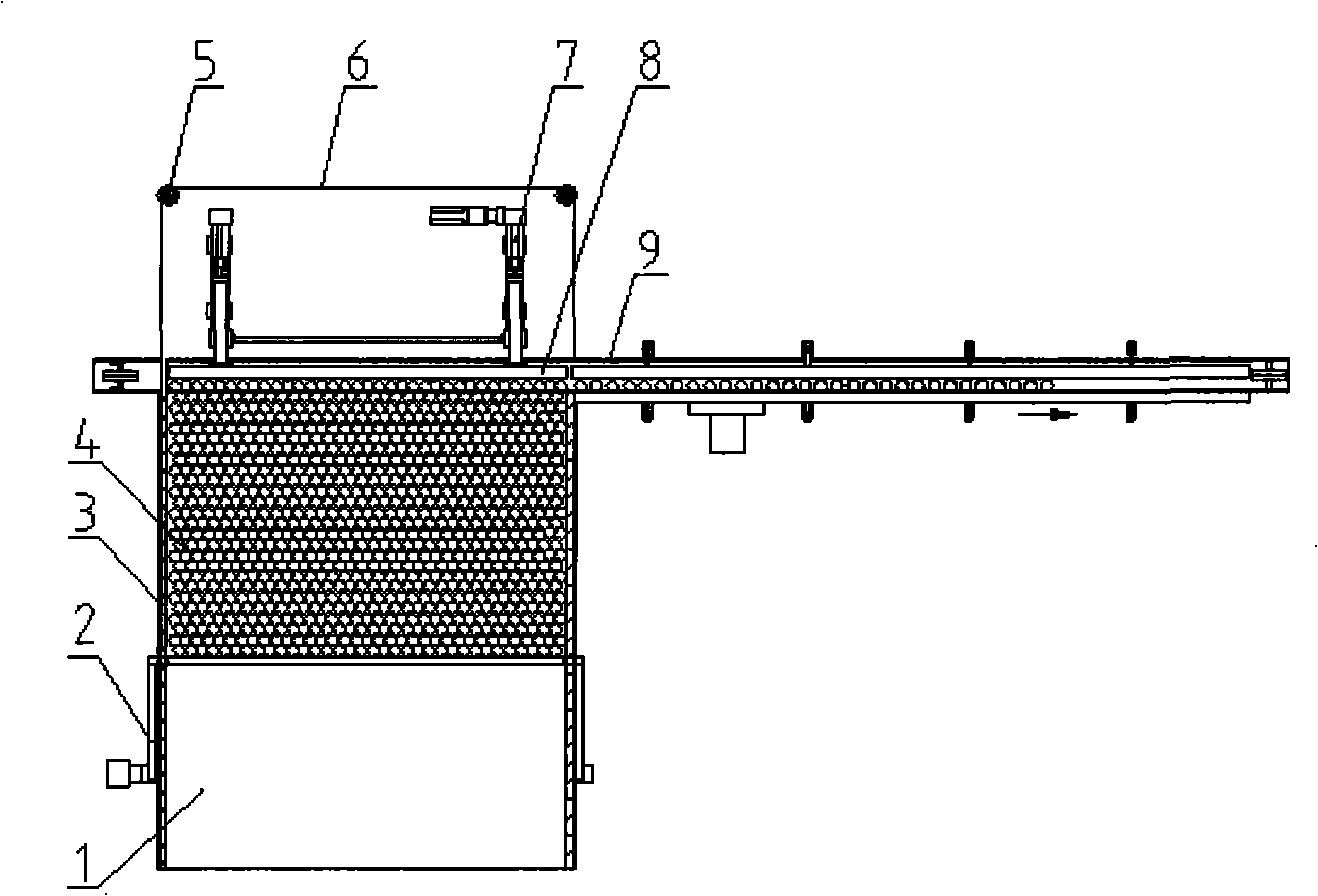

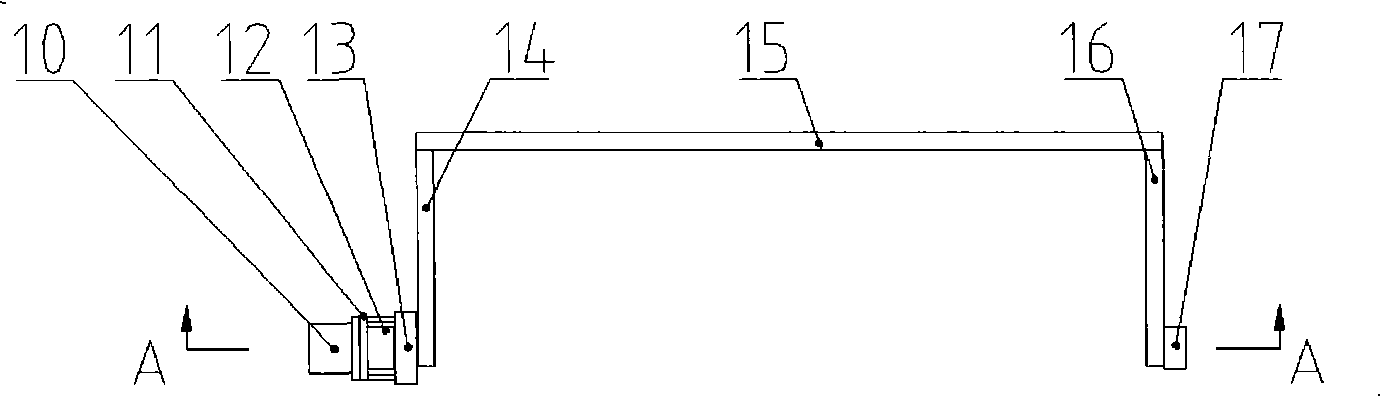

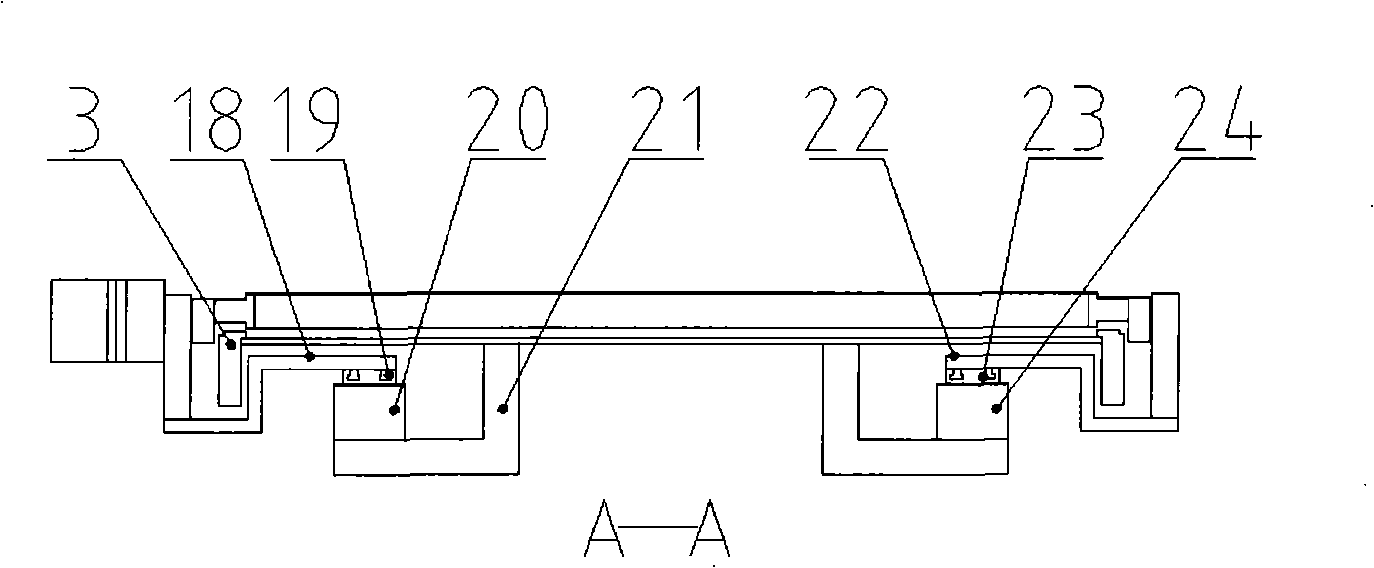

[0020] like figure 1 As shown, it is a structural schematic diagram of an automatic vial discharge device for a freeze dryer, and the described automatic vial discharge device for a freeze dryer consists of a loading table 1 and a discharge system component 2 , guide track 3, vial 4, support frame 5, decorative plate 6, propeller system component 7, push rod component 8 and conveyor system component 9.

[0021] Whole loading table 1, decorative plate 6 and pusher assembly 7 are supported by finely adjustable support frame 5, and conveyor system assembly 9 is connected with the end of loading table 1 to realize that vials 4 on loading table 1 can be moved from The conveyor system assembly 9 is transported out, the propeller system assembly 7 is arranged on the decorative plate 6 at the side end of the conveyor system assembly 9, the push rod assembly 8 is connected with the slider in the propeller system assembly 7, and the propeller system assembly 7 drives The push rod assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com