Method for controlling with 100aste newsprint paper deinked pulp esterase

A technology of newsprint and ink pulp ester, which is applied in the field of environment and resources, can solve the problems of complex components of stickies and not necessarily obvious effects of chemical fixatives, etc., and achieve the effect of increasing vehicle speed and output, and enhancing operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

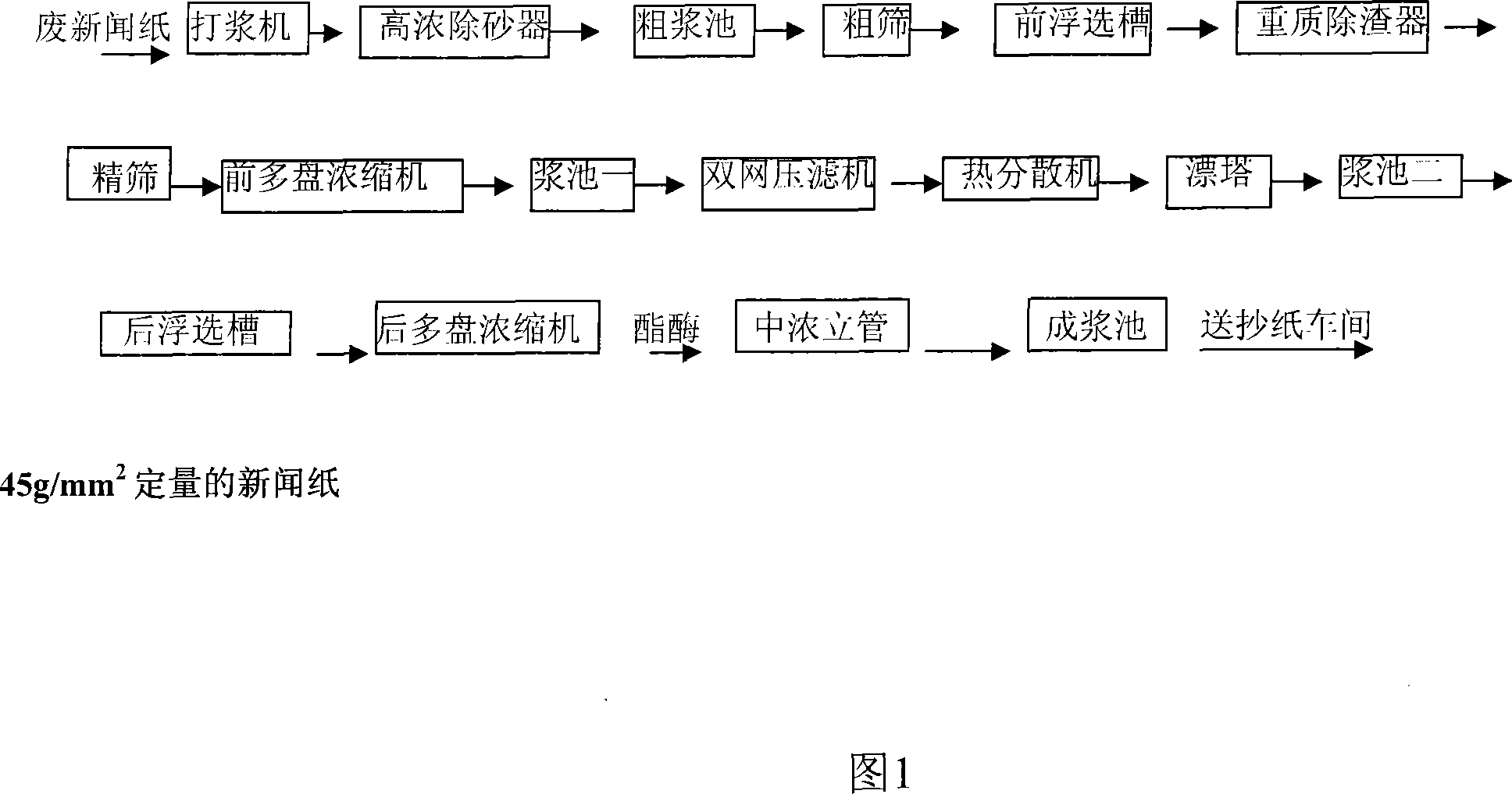

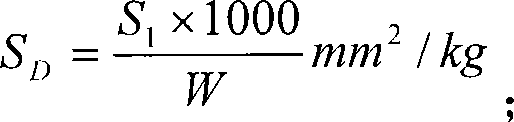

[0027] Adopt Optimyze525 enzyme product of Buckman company to produce 45g / mm in 100% ONP (waste newsprint) deinking pulp 2 Control of newsprint stickies.

[0028] (1) Waste newsprint (8# American waste paper 55%, waste forest paper 8%, European waste paper 13%, domestic waste paper 16%, 10# American waste paper 8%) mix evenly, then crush in a beater Pulp, control pulp concentration 15%, get 100% waste newsprint deinking pulp, then add NaOH 0.6%, NaOH 2 SiO 3 2.0%, H 2 o 2 0.4%, industrial soap 0.5%, deinking agent GOD1230 (Kunshan Zhongxuan Chemical Factory) 0.035%, adjust the pH value to 6.5, control the temperature at 50°C, and grind for 30 minutes to obtain a pulp solution.

[0029](2) above-mentioned pulping solution controls pulp concentration 12% in high concentration desander successively; Control pulp concentration in coarse stock pool is 3.5%; Control pulp concentration in coarse screen is 3.5%, inlet pressure is 250kPa, outlet pressure 110kPa; control the pulp...

Embodiment 2

[0043] (1) waste newsprint (55% of 8# American waste paper, 8% of waste forest paper, 13% of European waste paper, 16% of domestic waste paper, 8% of 10# American waste paper) mix well, and pulp in the beater , pulp concentration 16%, get 100% waste newsprint deinking pulp, then add NaOH 0.7%, NaOH 2 SiO 3 2.2%, H 2 o 2 0.6%, industrial soap 0.55%, deinking agent GOD1230 (Kunshan Zhongxuan Chemical Factory) 0.035%, the pH range is 10, the temperature is controlled at 60° C., and the pulping time is 45 minutes; a pulping solution is obtained.

[0044] (2) above-mentioned pulping solution controls pulp concentration 15% in high concentration desander successively; Control pulp concentration in coarse stock pool is 5%; Control pulp concentration in coarse screen is 3.0%, inlet pressure is 280kPa, outlet pressure 120kPa; control the pulp concentration to 1.2% in the front flotation tank, add industrial soap 0.09%; control the pulp concentration to 1.2% in the heavy slag remov...

Embodiment 3

[0052] (1) waste newsprint (55% of 8# American waste paper, 8% of waste forest paper, 13% of European waste paper, 16% of domestic waste paper, 8% of 10# American waste paper) mix well, and pulp in the beater , pulp concentration 18%, get 100% waste newsprint deinking pulp, then add NaOH 0.75%, NaOH 2 SiO 3 2.5%, H 2 o 2 1.0%, industrial soap 0.6%, deinking agent GOD1230 (Kunshan Zhongxuan Chemical Factory) 0.035%, the pH range is 8, the temperature is controlled at 55° C., and the pulping time is 40 minutes; a pulping solution is obtained.

[0053] (2) above-mentioned pulping solution controls pulp concentration 13% in the high-concentration desander successively; Control pulp concentration in coarse stock pool is 4%; Control pulp concentration in coarse screen is 5.0%, inlet pressure is 260 kPa, The outlet pressure is 115kPa; the pulp concentration is controlled at 1.5% in the front flotation tank, and 0.1% of industrial soap is added; the pulp concentration is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com