Veneering water-proofing multi-layer solid wood floor

A solid wood floor and veneer technology, applied in the direction of floors, insulating layers, buildings, etc., can solve the problems of surface hardness, lack of wear resistance, complex surface paint production process, black surface color, mildew and other problems, to achieve resistance to The effect of high grinding degree, protection of precious trees and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

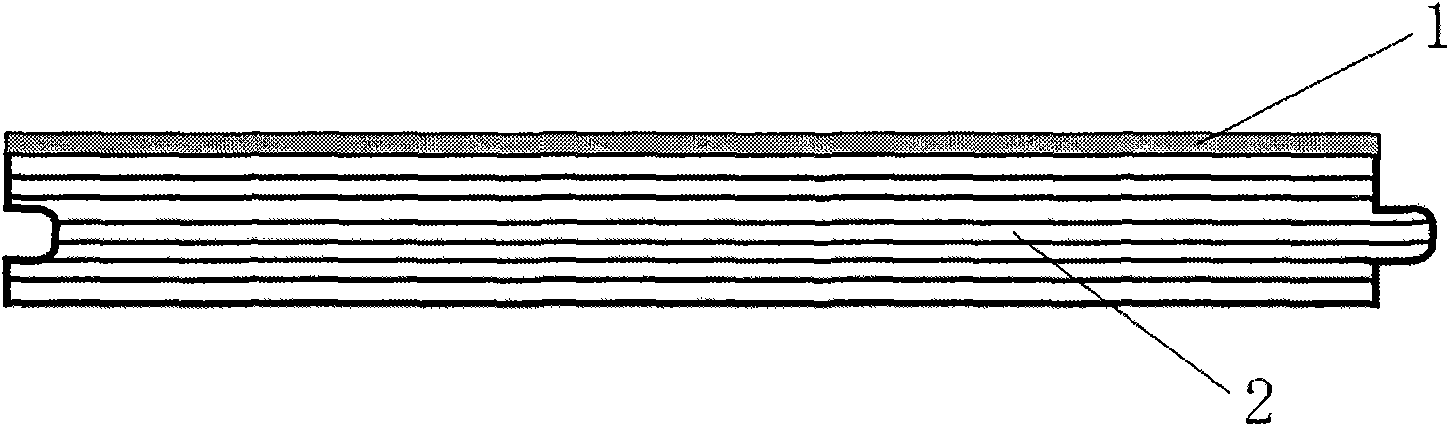

[0027] Such as figure 1 As shown, a veneer waterproof multilayer solid wood floor includes a base material board 2, which is a multilayer solid wood composite board, and the wood grains of adjacent solid wood single-layer boards of the multilayer solid wood composite board are crisscrossed in a crisscross pattern. , The layers are bonded by adhesive and hot pressed into a whole.

[0028] The thickness of the substrate plate 2 can be set according to the requirements of the finished product, and is generally selected to be 8 mm to 25 mm, and is preferably 18 mm in this embodiment.

[0029] The production of the base material board 2 adopts some small-caliber woods, which are cut into single-layer laminates of the required thickness (each 2 thickness is 1mm-3mm), and the single-pieces are glued and laid vertically and horizontally to the required thickness (The compression ratio of the thickness should be sufficient when the press is pressed), which is formed by high temperature and ...

Embodiment 2

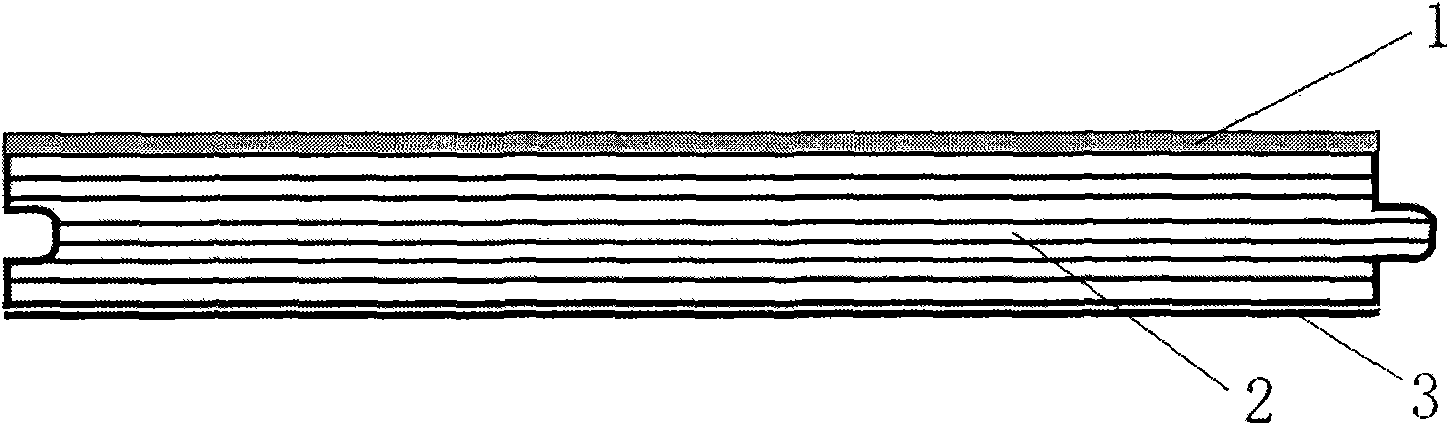

[0032] The difference between this embodiment and the first embodiment is: figure 2 As shown, the bottom surface of the base plate 2 is also provided with a moisture-proof film 3 to further prevent the intrusion of water vapor. The moisture-proof film 3 may be an aluminum-plastic composite film.

Embodiment 3

[0034] The difference between this embodiment and the first embodiment is that the bottom surface of the base material plate 2 is also provided with a plastic wear-resistant PVC finish, which can prevent the intrusion of moisture and maintain the balance of the floor, and the floor is not easy to warp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com